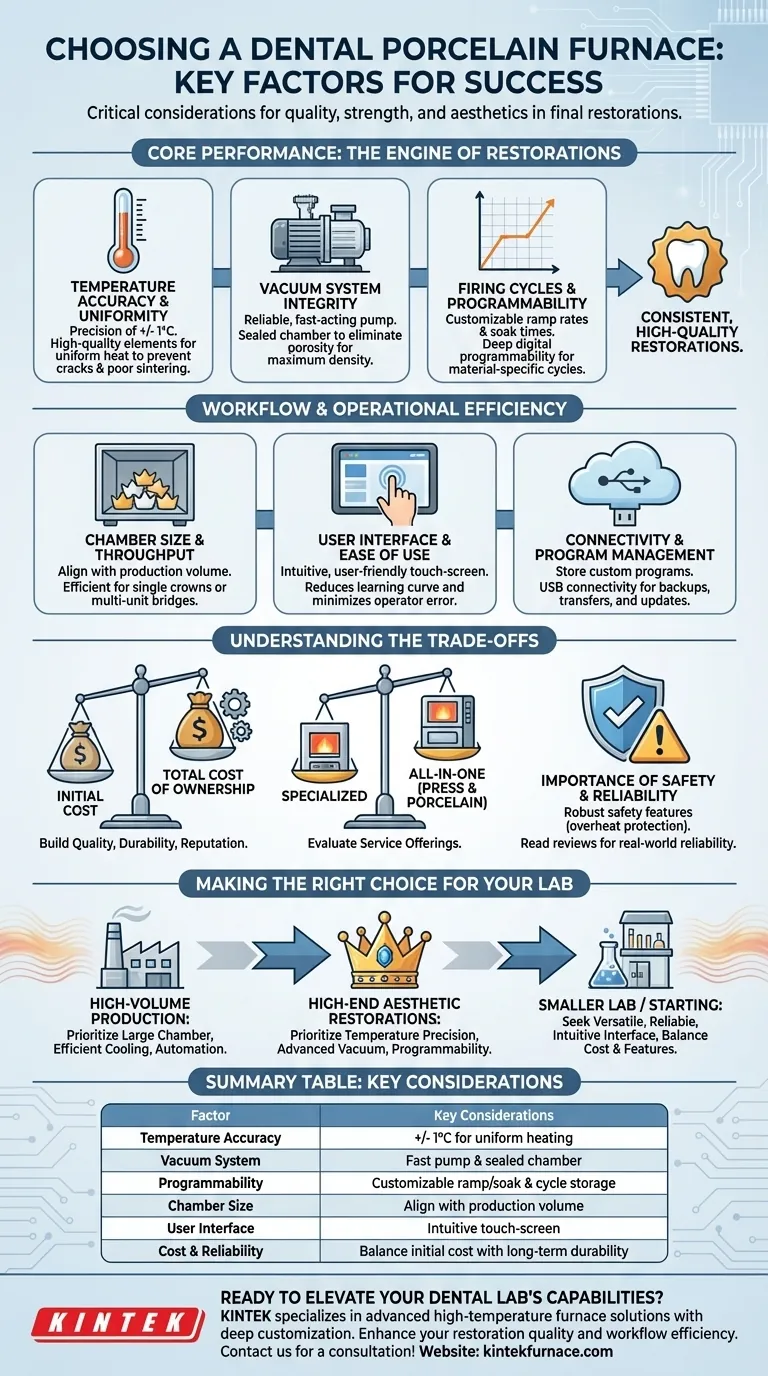

When selecting a dental porcelain furnace, the most critical factors are its temperature accuracy, vacuum system integrity, and the level of programmability it offers. These core features directly determine the quality, strength, and aesthetics of the final restoration, making them the foundation of a sound investment for any dental laboratory or practice.

The choice of a dental furnace is not merely a technical specification check. It is a decision that fundamentally impacts clinical outcomes, material compatibility, and workflow efficiency, defining your lab's capacity for producing consistent, high-quality restorations.

Core Performance: The Engine of Your Restorations

The primary function of a furnace is to execute a firing cycle with absolute precision. Any deviation can compromise the final product, leading to costly remakes and wasted time.

Temperature Accuracy and Uniformity

The furnace's ability to hit and hold a precise temperature is paramount. Look for systems that guarantee accuracy within +/- 1°C.

This precision relies on high-quality heating elements, such as silicon carbide, and an advanced chamber design that ensures uniform heat distribution. Uneven heating is a primary cause of cracks, poor sintering, and inconsistent shading.

Vacuum System Integrity

Many modern porcelains require a vacuum during the firing cycle to eliminate porosity and achieve maximum density and translucency.

A reliable, fast-acting vacuum pump and a perfectly sealed chamber are non-negotiable. The system must be able to pull a strong vacuum and maintain it without leakage throughout the cycle.

Firing Cycles and Programmability

Modern dental materials have highly specific firing requirements, including precise heating speeds (ramp rates), holding periods (soak times), and controlled cooling.

A furnace must offer deep digital programmability to customize and save these complex cycles. This ensures that you can perfectly match the firing parameters to the material manufacturer's instructions, every single time.

Workflow and Operational Efficiency

A furnace must integrate seamlessly into your lab's daily operations. A powerful machine that is difficult to use will only slow you down.

Chamber Size and Throughput

The furnace chamber size must align with your lab's production volume. A chamber that is too small will create a bottleneck, while an oversized one can be inefficient for smaller batches.

Consider both the current and future needs of your lab when evaluating the capacity for single crowns versus multi-unit bridges.

User Interface and Ease of Use

An intuitive, user-friendly interface, often a touch-screen, dramatically reduces the learning curve and minimizes the risk of operator error.

Clear displays and logical menu navigation allow technicians to select or program cycles quickly and confidently.

Connectivity and Program Management

The ability to store a large number of custom programs is essential for a lab working with diverse materials.

Modern features like USB connectivity simplify the process of backing up programs, transferring them between furnaces, or updating the furnace with new cycles provided by material manufacturers.

Understanding the Trade-offs

Making a wise investment requires looking beyond the spec sheet and considering the long-term implications of your choice.

Initial Cost vs. Total Cost of Ownership

A cheaper furnace may be appealing, but it can lead to higher long-term costs through frequent repairs, poor reliability, and failed restorations.

Prioritize build quality, durability, and brand reputation. A well-built furnace from a reputable manufacturer is an investment in consistency and peace of mind.

Specialized vs. All-in-One Furnaces

Some furnaces are designed purely for sintering and glazing, while others include pressing capabilities for materials like lithium disilicate.

Evaluate your service offerings. An all-in-one press and porcelain furnace can be a space-efficient and cost-effective solution for a versatile lab, but a dedicated furnace may offer superior performance for a specialized workflow.

The Importance of Safety and Reliability

The furnace operates at extreme temperatures and is a critical piece of your production line. Look for robust safety features, such as overheat protection and a well-insulated casing.

Consult with experienced peers and read reviews to gauge the real-world reliability and customer support offered by the manufacturer.

Making the Right Choice for Your Lab

Your final decision should be guided by your specific operational goals and the types of restorations you produce.

- If your primary focus is high-volume production: Prioritize a large chamber, a robust and efficient cooling system, and user-friendly automation features to maximize throughput.

- If your primary focus is high-end aesthetic restorations: Prioritize exceptional temperature precision, advanced vacuum control, and deep programmability to master complex materials.

- If you are a smaller lab or just starting: Seek a versatile, reliable furnace with an intuitive interface that balances cost with the features needed for a wide range of common materials.

Ultimately, choosing the right furnace is an investment in your lab's reputation and its ability to deliver excellence.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Temperature Accuracy | Must be within +/- 1°C for uniform heating and crack prevention |

| Vacuum System | Fast-acting pump and sealed chamber to eliminate porosity |

| Programmability | Customizable ramp rates, soak times, and cycle storage |

| Chamber Size | Align with production volume for crowns or bridges |

| User Interface | Intuitive touch-screen for ease of use and error reduction |

| Cost and Reliability | Balance initial cost with long-term durability and brand reputation |

Ready to elevate your dental lab's capabilities? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored for dental professionals. Leveraging our exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, and Vacuum Furnaces with deep customization to meet your unique needs for precise temperature control, reliable vacuum systems, and programmable cycles. Enhance your restoration quality and workflow efficiency—contact us today for a consultation and discover how our solutions can drive your success!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations