When selecting a zirconia sintering furnace, the decision hinges on a balance of clinical requirements, workflow efficiency, and long-term operational costs. Key factors include the furnace's temperature precision, processing capacity, and compatibility with the specific zirconia materials you use, as these directly impact the quality and consistency of your final restorations.

Your goal is not to buy the furnace with the most features, but the one that best aligns with your specific production volume and clinical objectives. A thoughtful choice is an investment in predictable outcomes, operational efficiency, and the long-term reliability of your practice or lab.

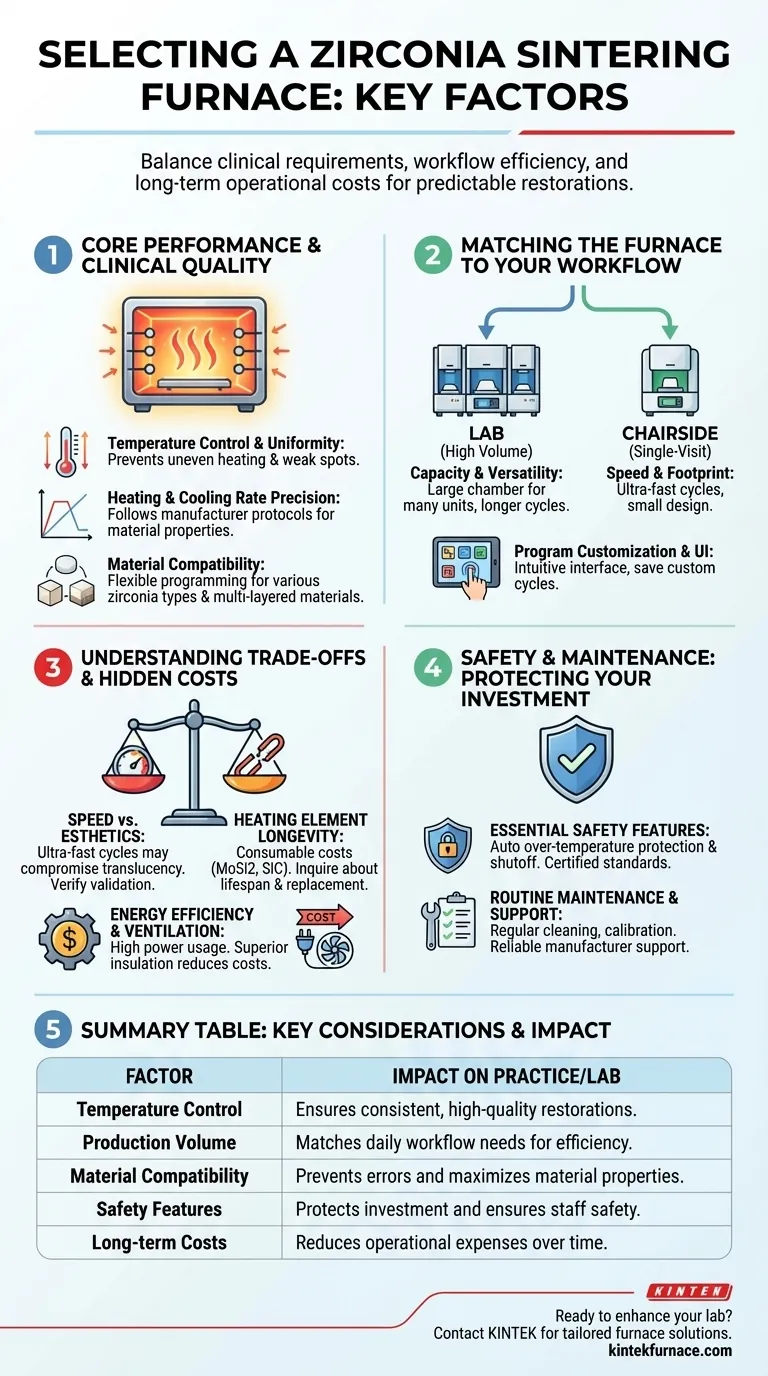

Core Performance and Clinical Quality

The primary function of a sintering furnace is to transform a milled zirconia restoration into a dense, strong, and esthetic final product. The furnace's ability to precisely control the environment is what determines success.

Temperature Control and Uniformity

A furnace must not only reach a target temperature, like 1550°C, but also maintain that temperature uniformly across the entire sintering chamber. Uneven heating creates internal stresses and inconsistent shrinkage, resulting in weak spots or restorations that do not fit. High-quality furnaces use multiple, well-placed thermocouples to monitor and regulate heat distribution for consistent densification.

Heating and Cooling Rate Precision

The rate at which the furnace heats up and cools down is just as critical as the peak temperature. Different types of zirconia—from high-strength to high-translucency—require specific heating and cooling profiles to achieve their intended properties. A furnace with precise, programmable control over these rates ensures you can follow the material manufacturer’s exact protocol, preventing thermal shock and maximizing esthetics.

Material Compatibility

Not all furnaces are optimized for all zirconia materials. A furnace's programming must be flexible enough to handle the specific sintering cycles required by your chosen brands. Before purchasing, verify that the furnace can accurately execute the temperature profiles for the zirconia you use most often, especially for newer multi-layered materials that may have complex requirements.

Matching the Furnace to Your Workflow

Beyond clinical output, the right furnace must integrate seamlessly into your daily operations. This involves matching its capacity, speed, and usability to the demands of your practice or lab.

Production Volume (Capacity vs. Speed)

Consider your daily and weekly production needs. A high-volume dental lab requires a furnace with a large chamber capable of sintering many units at once. In contrast, a dental practice focused on single-visit chairside restorations will prioritize a smaller, more compact furnace capable of ultra-fast sintering cycles.

Program Customization and User Interface

A modern, intuitive user interface is crucial for minimizing errors and improving efficiency. Look for furnaces with pre-loaded programs for common materials, as well as the ability to easily create and save custom cycles. This flexibility allows you to adapt to new materials and protocols without being locked into a limited set of options.

Chairside vs. Lab Applications

The distinction is significant. Furnaces designed for chairside use are engineered for speed and a small footprint, enabling same-day dentistry. Lab furnaces are workhorses built for volume, versatility, and running longer, more nuanced sintering cycles overnight. The components and design priorities for each are fundamentally different.

Understanding the Trade-offs and Hidden Costs

An objective evaluation requires looking past the marketing claims and understanding the inherent compromises and long-term expenses associated with any furnace.

The Speed vs. Esthetics Compromise

Ultra-fast sintering cycles are a major advantage for chairside workflows, but they can sometimes compromise the final esthetic properties, particularly the translucency, of certain zirconia materials. Always confirm that your zirconia is validated by the manufacturer for the specific rapid cycle you intend to use.

Heating Element Longevity

Heating elements, typically made of molybdenum disilicide (MoSi2) or silicon carbide (SiC), are consumable components with a finite lifespan. Their longevity is impacted by the frequency of use and the temperatures run. Inquire about the expected lifespan and replacement cost of the heating elements, as this is a significant long-term operational expense.

Energy Efficiency and Ventilation

A high-temperature furnace consumes a substantial amount of electricity. Models with superior insulation and more efficient heating technology can significantly reduce long-term energy costs. Additionally, all sintering furnaces require proper ventilation to safely manage heat and potential off-gassing, which may necessitate modifications to your facility.

Safety and Maintenance: Protecting Your Investment

A furnace is a major capital investment that requires proper care and safety protocols to ensure its longevity and protect your staff.

Essential Safety Features

Non-negotiable safety features include automatic over-temperature protection to prevent overheating and a reliable auto-shutoff mechanism. Ensure the furnace is certified by recognized safety standards and includes clear guidelines for safe operation.

Routine Maintenance and Manufacturer Support

To ensure consistent performance, furnaces require regular maintenance, including cleaning the chamber, inspecting the heating elements, and periodic temperature calibration. Choose a manufacturer with a strong reputation for reliability and responsive technical support to minimize downtime when service is inevitably required.

Making the Right Choice for Your Practice

Your decision should be guided by your primary operational goal.

- If your primary focus is single-visit, chairside restorations: Prioritize a compact, ultra-fast furnace specifically validated for rapid sintering of your chosen material.

- If you are a high-volume dental lab: Focus on a large-capacity furnace with robust, long-lasting heating elements and versatile programming for multiple zirconia types.

- If you are a boutique lab prioritizing esthetics: Emphasize furnaces with exceptionally precise temperature control and the flexibility to run slower, more complex sintering profiles.

- If you are a budget-conscious startup: Balance the initial purchase price with long-term operational costs like energy consumption and heating element replacement.

Ultimately, a well-chosen furnace becomes a silent, reliable partner in delivering consistent, high-quality restorations for years to come.

Summary Table:

| Factor | Key Consideration | Impact on Practice/Lab |

|---|---|---|

| Temperature Control | Precision and uniformity in heating | Ensures consistent, high-quality restorations |

| Production Volume | Capacity and speed of sintering cycles | Matches daily workflow needs for efficiency |

| Material Compatibility | Support for specific zirconia types | Prevents errors and maximizes material properties |

| Safety Features | Over-temperature protection and certifications | Protects investment and ensures staff safety |

| Long-term Costs | Heating element lifespan and energy efficiency | Reduces operational expenses over time |

Ready to enhance your dental lab's capabilities with a tailored zirconia sintering furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering reliable performance and cost savings. Contact us today to discuss how our furnaces can optimize your workflow and boost your success!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time