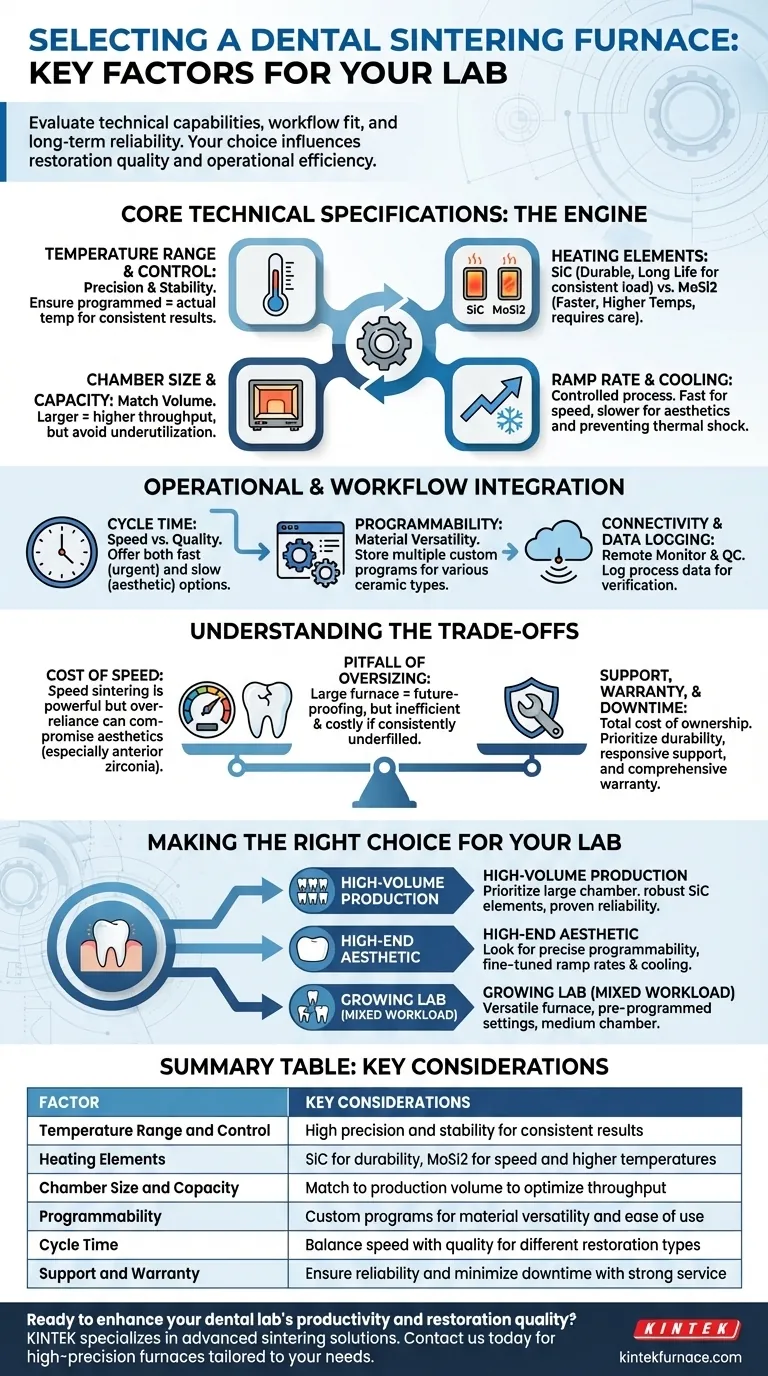

Selecting the right dental sintering furnace requires a balanced evaluation of its technical capabilities, its fit with your lab's specific workflow, and the long-term reliability of the manufacturer. The core factors are temperature precision, the type of heating elements used, chamber capacity, and programmability, all of which directly influence the quality of your restorations and the efficiency of your operations.

Your decision goes beyond a simple feature comparison. The optimal choice is a furnace that not only meets the technical demands of your current materials, like zirconia, but also aligns with your lab's production volume, future growth, and workflow efficiency.

Core Technical Specifications: The Engine of Your Furnace

The technical foundation of a furnace determines its performance ceiling. These specifications are non-negotiable indicators of the quality and consistency you can expect from your sintered restorations.

Temperature Range and Control

The ability to reach and hold precise temperatures is the single most important function of a sintering furnace. Inconsistent temperatures lead to weak or aesthetically flawed restorations.

Look for furnaces that guarantee high precision and stability, ensuring that the programmed temperature is the actual temperature inside the chamber, cycle after cycle.

Heating Elements: The Heart of the Furnace

The heating elements generate the thermal energy required for sintering. The two most common types are Silicon Carbide (SiC) and Molybdenum Disilicide (MoSi2).

SiC elements are known for their durability and long service life, making them a reliable choice for labs with consistent, heavy workloads.

MoSi2 elements can often heat up faster and reach higher temperatures, but may be more susceptible to contamination and require more careful handling.

Chamber Size and Capacity

The internal chamber size dictates your lab's throughput. This choice must be aligned with your daily production volume.

A larger chamber allows you to sinter more units at once, increasing efficiency for high-volume labs. However, consistently running a large, half-empty chamber is inefficient and wastes energy.

Ramp Rate and Cooling

The ramp rate is the speed at which the furnace heats up. While a faster ramp rate can shorten the total cycle time, some advanced zirconia materials require a slower, more controlled heating process to achieve optimal translucency and prevent thermal shock.

Efficient and controlled cooling is equally important for preventing cracks and ensuring the final strength of the restoration.

Operational and Workflow Integration

A technically superior furnace is only valuable if it integrates seamlessly into your lab's daily operations. Consider how the furnace will function within your existing workflow.

Cycle Time: Speed vs. Quality

Total cycle time—from heating to cooling—is a critical metric for lab productivity. Manufacturers often promote "speed sintering" cycles that can be completed in just a few hours.

These fast cycles are excellent for urgent cases, but they can sometimes compromise the final aesthetic properties, particularly the translucency of anterior zirconia. You need a furnace that provides both fast and slow, high-quality cycle options.

Programmability and Material Versatility

Your lab likely works with multiple types of ceramic materials, each with a unique, manufacturer-recommended sintering profile.

A furnace with a user-friendly interface and the ability to store multiple custom programs is essential. This adaptability ensures you can consistently achieve the best results for everything from high-strength posterior zirconia to highly translucent anterior materials.

Connectivity and Data Logging

Modern furnaces often include connectivity features like Wi-Fi or Ethernet ports. This allows for remote monitoring of cycle progress and, crucially, the logging of process data.

Data logs serve as an internal quality control record, verifying that every restoration was sintered according to the correct parameters.

Understanding the Trade-offs

An informed decision requires acknowledging the potential downsides and hidden costs associated with certain features. True value comes from balancing performance with practicality.

The True Cost of Speed

A furnace capable of extremely fast cycles is a powerful tool, but it's not a universal solution. Over-relying on speed sintering for all cases, especially high-aesthetic anterior crowns, can lead to remakes if the final shade and translucency don't meet expectations.

The Pitfall of Oversizing

Investing in the largest furnace available may seem like future-proofing, but it can be a significant drain on resources. A large chamber consumes more power per cycle, and the pressure to fill it can disrupt an otherwise efficient single-case workflow.

Support, Warranty, and Downtime

The purchase price is only one part of the total cost of ownership. A furnace breakdown means immediate, costly downtime for your lab.

Prioritize brands with a strong reputation for durability, responsive customer support, and a comprehensive warranty. This is your insurance policy against lost production and revenue.

Making the Right Choice for Your Lab

Your final selection should be a strategic decision based on your lab’s unique priorities and goals.

- If your primary focus is high-volume production: Prioritize a furnace with a large chamber, robust SiC heating elements, and a proven record of reliability for continuous use.

- If your primary focus is high-end aesthetic restorations: Look for a furnace with precise programmability, offering fine-tuned control over ramp rates and cooling to maximize material translucency.

- If you are a growing lab with a mixed workload: A versatile furnace with pre-programmed settings for various materials and a medium-sized chamber offers the best balance of flexibility and efficiency.

By moving beyond a simple feature list and focusing on how the furnace integrates with your specific workflow, you are investing not just in a piece of equipment, but in the consistent quality and future growth of your lab.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Temperature Range and Control | High precision and stability for consistent results |

| Heating Elements | SiC for durability, MoSi2 for speed and higher temperatures |

| Chamber Size and Capacity | Match to production volume to optimize throughput |

| Programmability | Custom programs for material versatility and ease of use |

| Cycle Time | Balance speed with quality for different restoration types |

| Support and Warranty | Ensure reliability and minimize downtime with strong service |

Ready to enhance your dental lab's productivity and restoration quality? KINTEK specializes in advanced sintering solutions tailored for dental laboratories. Leveraging exceptional R&D and in-house manufacturing, we offer a range of high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong deep customization capability, we can precisely meet your unique experimental and production needs. Contact us today to discuss how our reliable, high-precision furnaces can support your lab's growth and efficiency!

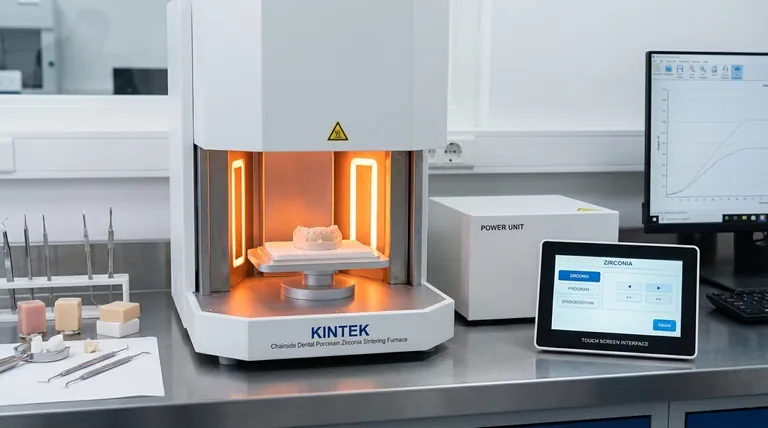

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time