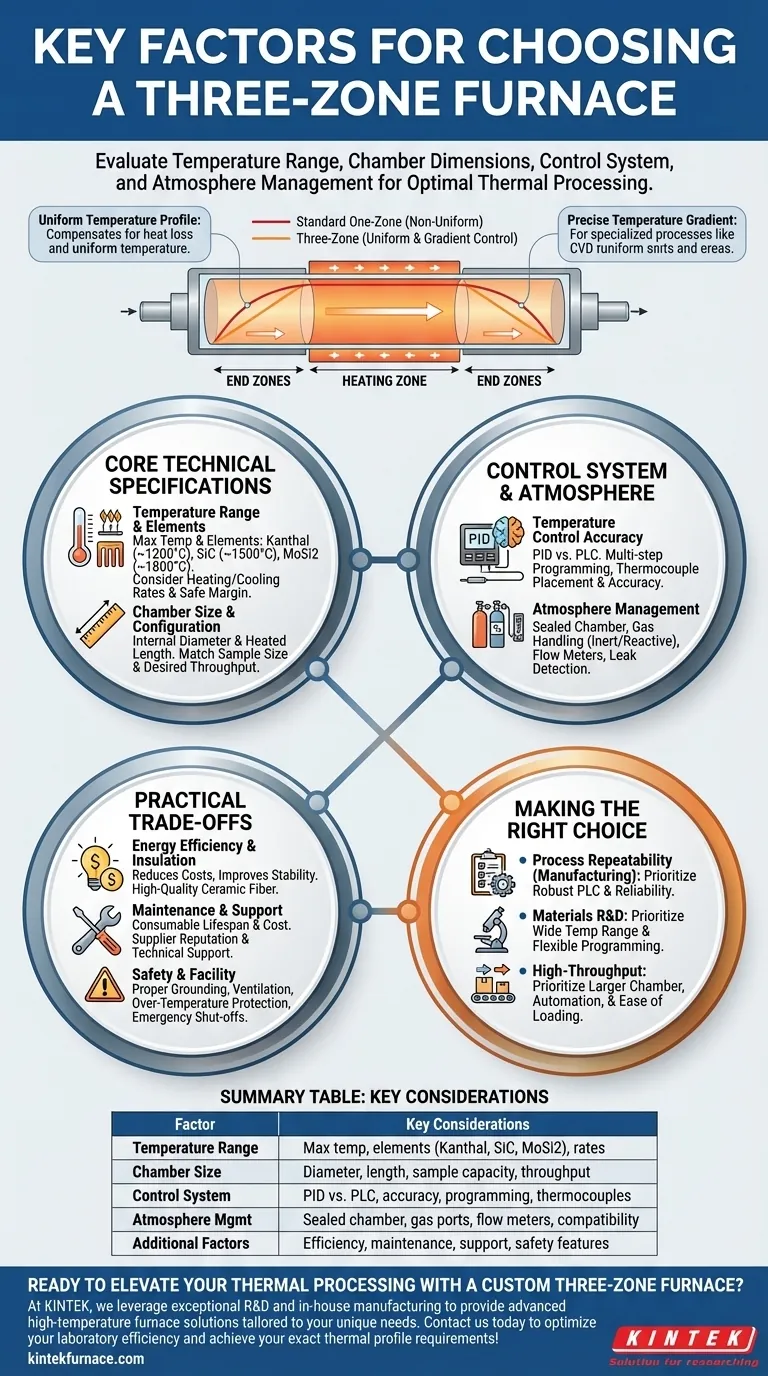

When purchasing a three-zone furnace, the most critical factors to evaluate are its temperature range, chamber dimensions, control system precision, and its ability to manage specific gas atmospheres. These four pillars dictate the furnace's suitability for your specific thermal processing application, from its physical capacity to the chemical environment it can create.

The goal is not simply to buy a furnace that gets hot, but to procure a precision instrument that can reliably and repeatedly execute your exact thermal profile. A mismatched furnace leads to failed processes, wasted materials, and compromised research.

Why a Three-Zone Furnace?

A standard furnace has one heating zone, which often results in temperature drop-off near the ends. A three-zone furnace solves this by using a central heating zone flanked by two end zones, each with its own independent controller and sensor.

The Principle of Thermal Gradient Control

This multi-zone design allows you to achieve two primary outcomes. First, you can create a highly uniform temperature profile across a longer length of the chamber by setting the end zones to a slightly higher temperature, compensating for natural heat loss.

Second, you can intentionally create a precise temperature gradient. This is essential for specialized applications like chemical vapor deposition (CVD) or crystal growth, where different temperature stages are required within a single process.

Core Technical Specifications

These are the non-negotiable specifications that form the foundation of your decision. An error here means the furnace will be fundamentally incompatible with your work.

Temperature Range and Heating Elements

The furnace's maximum temperature is determined by its heating elements. Common types include Kanthal (up to ~1200°C), Silicon Carbide (SiC, up to ~1500°C), and Molybdenum Disilicide (MoSi2, up to ~1800°C).

Ensure the furnace's maximum rated temperature provides a safe margin above your highest required process temperature. Also, consider the heating and cooling rates, as rapid cycling can be crucial for some applications but may stress certain materials.

Chamber Size and Configuration

The internal chamber, often a ceramic tube, must accommodate your samples. Consider the required internal diameter and overall heated length.

Think in terms of both sample dimensions and desired throughput. A larger chamber can process more or bigger samples at once but will have higher energy consumption and may heat more slowly.

The Brain of the Operation: Control and Atmosphere

Modern furnaces are defined by their control systems. This is what transforms a simple heat source into a precision scientific tool.

Temperature Control and Accuracy

The furnace's controller executes your temperature commands. A basic PID (Proportional-Integral-Derivative) controller is standard, but a PLC (Programmable Logic Controller) offers more robust and complex automation possibilities.

Accuracy is paramount. Look for systems that allow for multi-step programming to create complex thermal cycles. The placement and type of thermocouples are also critical for ensuring the measured temperature reflects the actual sample temperature.

Atmosphere Management

Many processes require a specific gaseous environment. If you need to prevent oxidation or introduce reactive gases, the furnace must have a sealed chamber and gas handling capabilities.

This includes inlet and outlet ports, a flow meter, and compatibility with inert gases (like Argon or Nitrogen) or reducing gases. Ensure the seals and components are rated for your specific process gases.

Understanding the Practical Trade-offs

A furnace's datasheet only tells part of the story. You must also consider the long-term operational and facility implications.

Energy Efficiency and Insulation

A well-insulated furnace not only reduces operational costs by minimizing heat loss but also contributes to a more stable and uniform thermal environment. High-quality ceramic fiber insulation is the industry standard.

The Hidden Costs: Maintenance and Support

Heating elements and thermocouples are consumables with a finite lifespan. Inquire about the cost and availability of replacements.

Furthermore, evaluate the supplier's reputation and after-sales support. When a multi-thousand-dollar piece of equipment fails, prompt and knowledgeable technical support is invaluable.

Safety and Facility Requirements

These are not features but prerequisites. The furnace requires proper grounding to prevent electrical hazards and must be installed in a well-ventilated area, away from any flammable materials.

If you are using process gases, you must have leak detection systems and safe gas storage and handling protocols in place. Always ensure the system includes over-temperature protection and emergency shut-offs.

Making the Right Choice for Your Application

Your final decision should be guided by your primary objective.

- If your primary focus is process repeatability and quality control (e.g., manufacturing): Prioritize a robust PLC control system with data logging and a furnace from a supplier with a strong reputation for reliability.

- If your primary focus is materials research and development: Prioritize a wide temperature range, versatile atmosphere control capabilities, and a flexible programming interface.

- If your primary focus is high-throughput sample processing: Prioritize a larger chamber size, ease of loading and unloading, and potential automation features.

Ultimately, selecting the right three-zone furnace is an exercise in precisely matching the equipment's capabilities to your scientific or production goals.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Temperature Range | Max temperature, heating elements (e.g., Kanthal, SiC, MoSi2), heating/cooling rates |

| Chamber Size | Internal diameter, heated length, sample capacity, throughput |

| Control System | PID vs. PLC controllers, thermocouples, multi-step programming, accuracy |

| Atmosphere Management | Sealed chamber, gas ports, flow meters, compatibility with inert/reactive gases |

| Additional Factors | Energy efficiency, maintenance costs, supplier support, safety features |

Ready to elevate your thermal processing with a custom three-zone furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're in research, manufacturing, or high-throughput processing, we ensure precise temperature control, uniform heating, and reliable performance. Contact us today to discuss how we can optimize your laboratory efficiency and achieve your exact thermal profile requirements!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What materials can be used to make the rotating tube assembly of these furnaces? Choose the Best for Your High-Temp Needs

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing