To ensure the longevity of a muffle furnace, you must look beyond the maximum temperature and chamber size. The most critical factors are the design features that protect core components from heat and chemical corrosion, such as the placement of heating elements, the quality of the insulation, and the presence of an effective ventilation system. These elements, combined with a precise controller, are the true indicators of a durable and reliable instrument.

A long-lasting muffle furnace is not simply one that is well-built; it is one where the construction materials and design are correctly matched to the specific chemical and thermal stresses of your intended application.

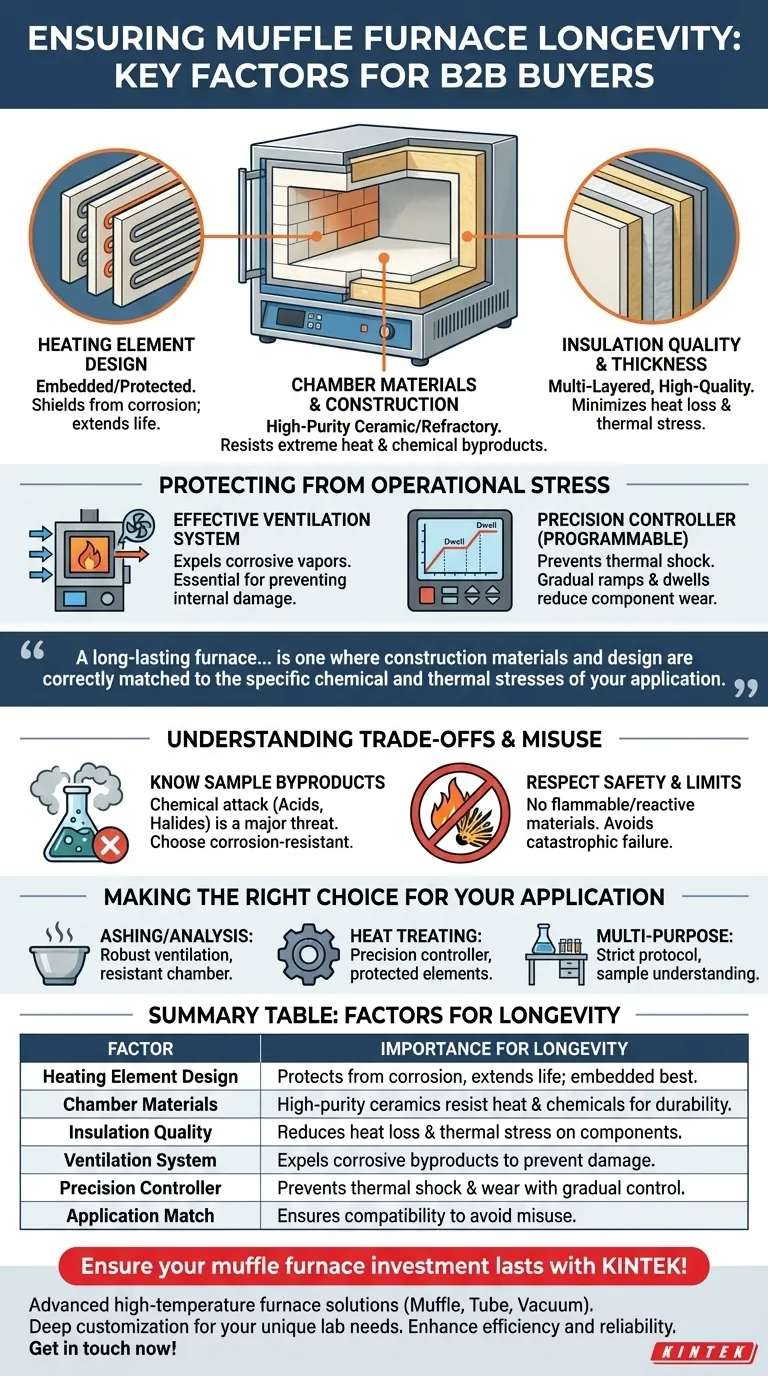

Core Components That Define Durability

The lifespan of a muffle furnace is fundamentally determined by the quality and design of its essential components. Scrutinizing these areas will reveal how well the furnace is built to withstand repeated, high-temperature use.

Heating Element Design and Placement

Heating elements are the heart of the furnace and a common point of failure. Their longevity is directly tied to their protection.

Elements embedded within the insulation or placed behind a ceramic plate are shielded from corrosive vapors and accidental contact. This design significantly extends their life compared to exposed-wire elements.

Chamber Materials and Construction

The furnace chamber must endure extreme thermal cycling. The material it's made from is therefore critical.

Look for chambers constructed from high-purity ceramic fiber or dense refractory brick. These materials offer excellent resistance to high temperatures and the chemical byproducts that may be released from your samples.

Insulation Quality and Thickness

Effective insulation does more than save energy; it protects the entire furnace structure.

High-quality, multi-layered insulation minimizes heat loss, which keeps the outer casing cool and reduces thermal stress on electronic components and the furnace body. This stability contributes directly to a longer operational life.

Protecting Your Investment from Operational Stress

How a furnace manages the byproducts of its own operation is just as important as its static build quality. Features that mitigate operational stress are a hallmark of a well-engineered, long-lasting unit.

The Critical Role of Ventilation

Many heating processes, such as ashing, release vapors, fumes, and gases. If not properly managed, these byproducts will aggressively corrode the chamber and heating elements.

A built-in, adjustable air vent is not an optional feature; it is essential for longevity. It allows you to expel these harmful substances, preserving the integrity of the furnace interior.

Precision Control for Reduced Wear

The controller dictates the heating and cooling cycles. A basic controller can introduce thermal shock, which stresses all furnace components.

A programmable, multi-stage controller allows for gradual temperature ramps and dwells. This precision prevents thermal shock from rapid temperature changes and avoids overshooting the setpoint, reducing wear on the heating elements and chamber materials over thousands of cycles.

Understanding the Trade-offs and Misuse

Even the best furnace will fail prematurely if used improperly. Understanding its limitations is key to ensuring a long service life.

Know Your Sample's Byproducts

The single greatest threat to a muffle furnace is chemical attack from an incompatible sample.

Materials that release acids, halides (like chlorides), or heavy metals can rapidly degrade insulation and heating elements. If your application involves such materials, you must select a furnace specifically designed with corrosion-resistant components.

Respecting Safety and Operational Limits

A muffle furnace is designed for controlled atmospheric heating, not for volatile reactions.

Never place flammable, explosive, or highly reactive materials inside the furnace. Such misuse is not only extremely dangerous but can cause catastrophic failure of the unit.

Muffle Furnace vs. Vacuum Furnace

It is critical to use the right tool for the job. A muffle furnace is designed to operate in air.

If your process requires an inert atmosphere or a vacuum, you need a vacuum furnace. Attempting to create a vacuum in a muffle furnace is ineffective and can damage the seals and chamber.

Making the Right Choice for Your Application

Use your specific process as the primary guide for your selection.

- If your primary focus is ashing or material analysis: Prioritize a furnace with robust ventilation and a chemically resistant chamber to handle corrosive byproducts.

- If your primary focus is general heat treating or annealing: Emphasize a precision controller for gradual thermal cycles and well-protected heating elements for maximum durability.

- If your primary focus is for a multi-purpose lab: Select a versatile unit but instill a strict protocol of understanding sample characteristics before each use to prevent damage.

By matching the furnace's design features to your specific application, you are making an investment in long-term reliability.

Summary Table:

| Factor | Importance for Longevity |

|---|---|

| Heating Element Design | Protects from corrosion and extends life; embedded elements are best. |

| Chamber Materials | High-purity ceramics resist heat and chemicals for durability. |

| Insulation Quality | Reduces heat loss and thermal stress on components. |

| Ventilation System | Expels corrosive byproducts to prevent internal damage. |

| Precision Controller | Prevents thermal shock and wear with gradual temperature control. |

| Application Match | Ensures compatibility with sample types to avoid misuse. |

Ensure your muffle furnace investment lasts for years with KINTEK! We specialize in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Leveraging exceptional R&D and in-house manufacturing, we offer deep customization to precisely meet your lab's unique needs—whether for ashing, heat treating, or multi-purpose applications. Contact us today to discuss how our durable, tailored furnaces can enhance your lab's efficiency and reliability. Get in touch now!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control