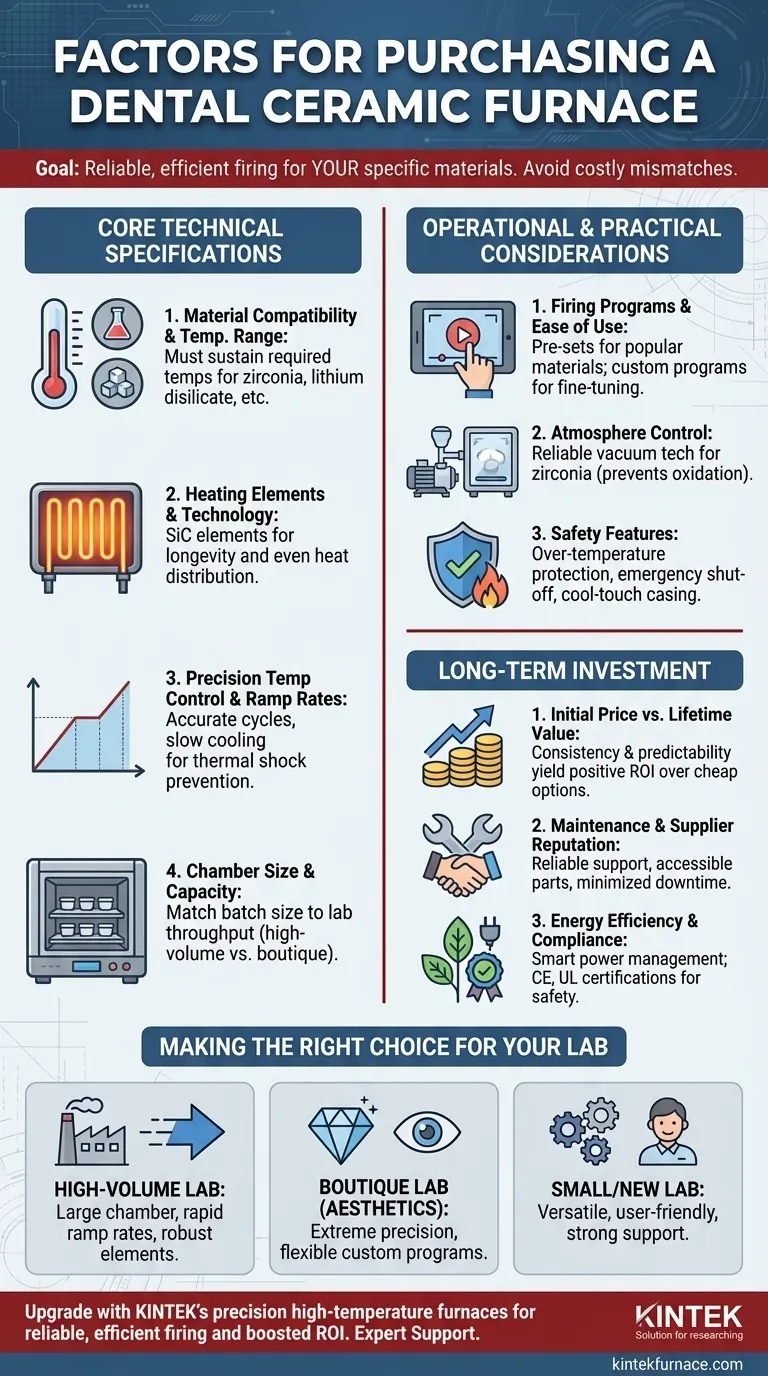

When purchasing a dental ceramic furnace, the key factors to consider are its material compatibility, temperature precision, heating technology, and chamber size. These elements directly impact the quality, consistency, and efficiency of your dental restorations, making the decision a critical investment in your lab's capabilities.

The ultimate goal is not to buy the furnace with the most features, but the one that most reliably and efficiently fires the specific ceramic materials your lab depends on. A mismatch between furnace capabilities and material requirements is the most common and costly mistake, leading to remakes and inconsistent results.

Core Technical Specifications

The technical capabilities of a furnace determine the final physical and aesthetic properties of the ceramic. These specifications are not negotiable and must align with your materials.

Material Compatibility and Temperature Range

This is the most crucial factor. Different dental ceramics, such as lithium disilicate, zirconia, and layered porcelains, require very specific firing temperatures and cycles.

The furnace you choose must be capable of reaching and sustaining the temperatures required by the materials you use most. Check the manufacturer's specifications for both the furnace and your ceramic materials to ensure they are compatible.

Heating Elements and Technology

The heating elements are the engine of the furnace. They are responsible for generating heat evenly and consistently.

Elements made from materials like silicon carbide (SiC) are often preferred for their longevity and ability to maintain stable temperatures, even after extensive use. The quality of the elements directly affects the predictability of your firing outcomes.

Precision Temperature Control and Ramp Rates

Aesthetic success in ceramics depends on precision. The furnace's control system must be able to follow a programmed firing cycle with minimal deviation.

The ramp rate—the speed at which the furnace heats up and cools down—is also critical. Slow, controlled cooling is essential for some materials to prevent thermal shock and cracking, while rapid heating can improve efficiency.

Chamber Size and Capacity

The internal size of the firing chamber dictates your lab's throughput. Consider the number and size of the restorations you typically produce in a single batch.

A larger chamber is ideal for high-volume production labs, while a smaller, more compact furnace may be more energy-efficient and suitable for a boutique lab or a dental office.

Operational and Practical Considerations

Beyond the core technology, you must evaluate how the furnace will fit into your daily workflow and long-term operations.

Firing Programs and Ease of Use

Modern furnaces often come with pre-set programs for popular materials, which simplifies operation and reduces the risk of human error.

However, the ability to create and save custom programs is invaluable for experienced technicians who wish to fine-tune their results. An intuitive user interface and clear display reduce the learning curve and improve daily efficiency.

Atmosphere Control

Some advanced ceramic processes, particularly for zirconia, require firing in a specific atmosphere, such as a vacuum, to prevent oxidation and achieve the desired translucency and strength.

If you work with these materials, ensure the furnace has reliable vacuum pump technology and sealing capabilities.

Safety Features

A furnace operates at extremely high temperatures, making safety non-negotiable. Look for essential features like over-temperature protection, which prevents overheating, and an emergency shut-off.

A well-insulated casing that stays cool to the touch is also a critical safety and energy-efficiency feature.

Understanding the Long-Term Investment

A furnace is a long-term asset, and the initial purchase price is only one part of its total cost of ownership.

Initial Price vs. Lifetime Value

An inexpensive furnace that produces inconsistent results is a liability. The cost of remakes, wasted materials, and dissatisfied clients will quickly eclipse any initial savings.

Invest in a furnace that delivers predictable and repeatable results. This consistency is what produces a positive return on investment.

Maintenance and Supplier Reputation

Regular maintenance, such as cleaning the chamber, calibrating temperature sensors, and eventually replacing heating elements, is essential.

Choose a manufacturer with a strong reputation for reliability and responsive technical support. Knowing you can get parts and service quickly is crucial for minimizing downtime.

Energy Efficiency and Compliance

An energy-efficient furnace will reduce your lab's operating costs over the long term. Look for models with superior insulation and smart power management.

Furthermore, ensure the furnace has the necessary certifications (like CE or UL) to comply with local safety and electrical standards.

Making the Right Choice for Your Lab

Your choice should be guided by your lab's specific operational needs and clinical goals.

- If your primary focus is a high-volume production lab: Prioritize a furnace with a large chamber, rapid ramp rates, and robust, long-lasting heating elements to maximize throughput.

- If your primary focus is a boutique lab specializing in high-aesthetics: Emphasize a furnace with extremely precise temperature control and the flexibility for custom firing programs to perfect shade and translucency.

- If your primary focus is a small or new lab: Focus on a versatile, user-friendly furnace from a reputable brand that can handle common materials and offers excellent technical support.

Ultimately, the right furnace is a direct extension of your skill, enabling you to consistently deliver high-quality, aesthetic restorations to your clients.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Material Compatibility | Must match specific ceramics (e.g., lithium disilicate, zirconia) and required temperature ranges |

| Temperature Precision | Essential for aesthetic outcomes; requires accurate control and programmable ramp rates |

| Heating Technology | Silicon carbide elements for longevity and even heating; affects firing consistency |

| Chamber Size | Dictates throughput; choose based on lab volume (e.g., large for high-volume, small for boutique) |

| Ease of Use | Pre-set and custom firing programs with intuitive interfaces to reduce errors |

| Safety Features | Over-temperature protection, emergency shut-off, and cool-touch insulation |

| Long-Term Value | Consider maintenance, supplier support, energy efficiency, and certifications (e.g., CE, UL) |

Upgrade your dental lab with KINTEK's precision high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like Muffle, Tube, and Vacuum Furnaces, tailored to your unique needs. Whether you're a high-volume production lab, a boutique specialist, or a small startup, our deep customization ensures reliable, efficient firing for materials like zirconia and lithium disilicate. Contact us today to enhance your restoration quality and boost ROI with our expert support!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations