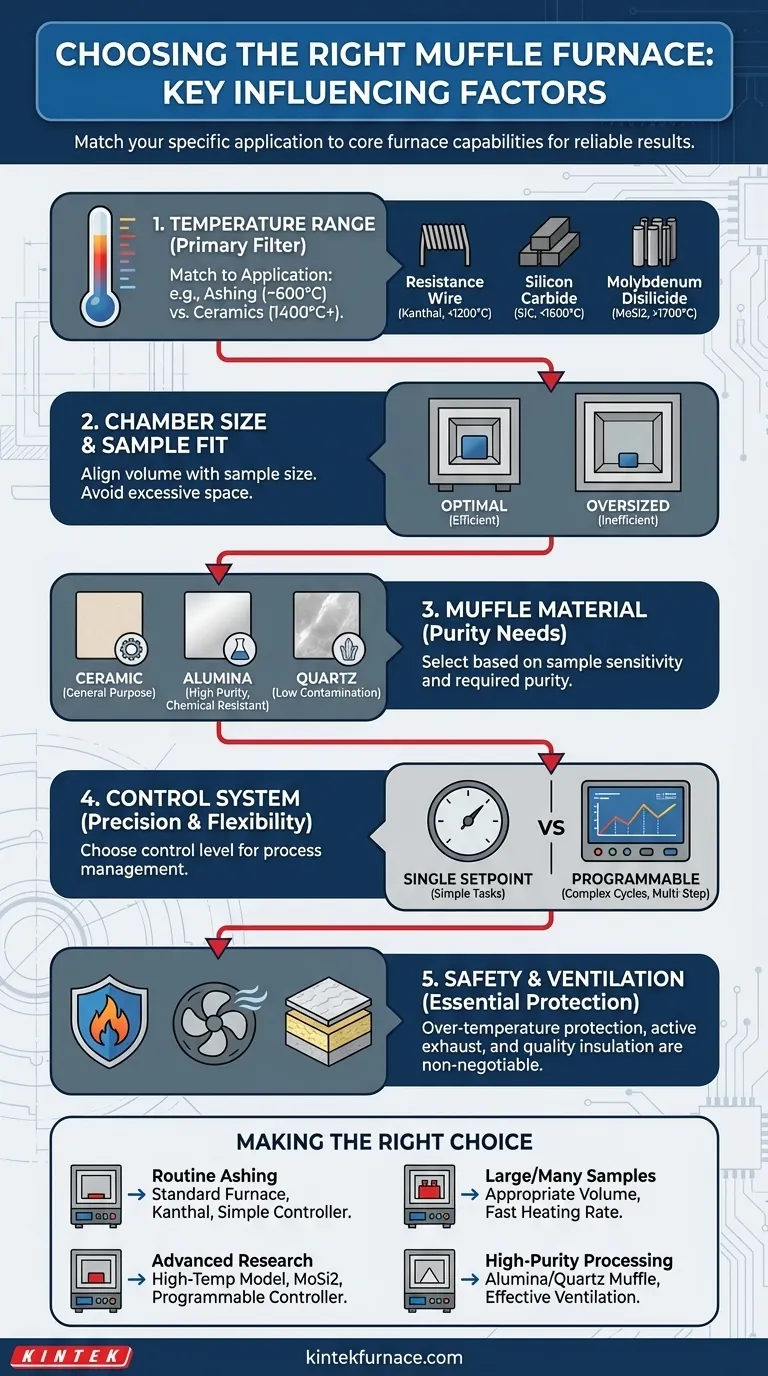

Choosing the right muffle furnace involves a systematic evaluation of your specific application against the furnace's core capabilities. The most critical factors are the required temperature range, the size and nature of your samples, the necessary heating performance and control precision, and essential safety features. Understanding these elements ensures you select a tool that delivers reliable and repeatable results for your work.

A muffle furnace is not a one-size-fits-all device. The optimal choice is not the furnace with the highest specifications, but the one whose temperature range, chamber material, and control system are precisely matched to the demands of your specific material and process.

Defining Your Core Requirement: Temperature

The maximum operating temperature is the first and most important filter in your selection process. It dictates the types of materials you can process and directly influences the furnace's construction and cost.

Match Temperature to Your Application

Different processes have distinct thermal requirements. For example, general ashing of organic matter might only require 600°C, while testing certain polymer or ceramic compounds can demand temperatures of 1400°C or higher.

Using a furnace with an inadequate temperature range can lead to incomplete reactions or sample degradation, compromising the integrity of your results.

The Role of Heating Elements

The furnace's temperature capability is determined by its heating elements.

- Resistance Wire (Kanthal, Nichrome): Common in general-purpose furnaces, typically reaching up to 1200°C.

- Silicon Carbide (SiC): Used for higher temperature applications, often up to 1500°C or 1600°C.

- Molybdenum Disilicide (MoSi2): Found in high-performance furnaces capable of exceeding 1700°C.

Choosing a furnace with elements rated significantly above your required temperature can provide a longer service life, as they will not be operating at their absolute limit.

Sizing the Furnace: Chamber and Sample

The physical dimensions of the furnace must accommodate your samples, but "bigger" is not always better.

Align Chamber Volume with Sample Size

Select a chamber size that comfortably fits your largest sample or batch without excessive empty space. An oversized chamber is less energy-efficient, takes longer to heat up, and has a higher initial cost.

Conversely, a chamber that is too small can restrict airflow, lead to uneven heating, and limit your sample throughput.

Consider the Muffle Material

The internal chamber, or muffle, isolates the sample from the heating elements. Its material is critical.

- Refractory Ceramic: The most common material, suitable for a wide range of applications.

- Alumina: Offers higher purity and better resistance to chemical attack at high temperatures.

- Quartz: Used when even trace contamination from the chamber walls is a concern, though it often has a lower maximum temperature limit.

Evaluating Performance and Control

Beyond just reaching a temperature, how the furnace gets there and maintains it is crucial for process control.

Heating Rate and Uniformity

The heating rate (°C per minute) determines how quickly the furnace reaches its setpoint, impacting overall process time. Equally important is temperature uniformity, which ensures the entire sample experiences the same thermal conditions.

Check for specifications on temperature uniformity and consider if a fan-assisted model is necessary for your application to ensure consistent heating.

The Controller: From Simple to Complex

The furnace's control system is its brain.

- Single Setpoint Controller: Allows you to set a single target temperature. This is sufficient for simple processes like drying or ashing.

- Programmable Controller: Enables you to create multi-step programs with different temperatures, hold times, and heating/cooling rates. This is essential for complex heat-treating, sintering, or materials synthesis protocols.

Understanding the Trade-offs and Safety Imperatives

A reliable furnace is a safe furnace. Non-negotiable safety features protect the user, the sample, and the equipment itself.

Prioritizing Essential Safety Features

Your furnace must have over-temperature protection, which automatically shuts down power if the temperature exceeds a preset safety limit. Other key features include electrical circuit breakers and audible alarms.

The Need for Ventilation

Many high-temperature processes release fumes, gases, or moisture. An exhaust port or system is critical for safely venting these byproducts from the chamber and the lab environment.

Insulation and Energy Efficiency

The quality of the insulation (typically ceramic fiber or mineral wool) directly impacts heat loss. Better insulation means the furnace is more energy-efficient, has a lower external surface temperature, and can maintain its setpoint more accurately. This often represents a trade-off between upfront cost and long-term operating expense.

Making the Right Choice for Your Goal

Select your furnace by prioritizing the features that align with your primary objective.

- If your primary focus is routine ashing or burnout: A standard furnace with Kanthal elements, a ceramic muffle, and a simple setpoint controller is a cost-effective choice.

- If your primary focus is advanced materials research: Prioritize a high-temperature model with MoSi2 elements and a fully programmable controller for complex thermal cycles.

- If your primary focus is processing large or numerous samples: Select a furnace with the appropriate chamber volume and a fast heating rate to maximize throughput.

- If your primary focus is high-purity processing: Invest in a furnace with a high-purity alumina or quartz muffle and ensure it has an effective ventilation system.

By systematically matching these factors to your specific process, you ensure your investment yields accurate, repeatable, and safe results.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Temperature Range | Match to application (e.g., 600°C for ashing, 1400°C+ for ceramics); heating elements (Kanthal, SiC, MoSi2) define limits |

| Chamber Size | Align with sample dimensions; avoid oversizing for efficiency and uniform heating |

| Muffle Material | Choose based on purity needs: ceramic (general), alumina (high purity), quartz (low contamination) |

| Control System | Select from single setpoint (simple tasks) to programmable (complex cycles) for precise temperature management |

| Safety Features | Ensure over-temperature protection, ventilation, and insulation for user and equipment safety |

Ready to find the perfect muffle furnace for your lab? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need precise temperature control, enhanced safety, or tailored designs, we deliver reliable, efficient solutions. Contact us today to discuss how we can optimize your thermal processes and boost your research outcomes!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary use of a muffle furnace in the assembly of side-heated resistive gas sensors? Expert Annealing Guide

- Why is a muffle furnace used to determine the ash content of biochar? Master Your Material Purity Analysis

- How does a muffle furnace contribute to kaolin-modified biochar? Optimize Pyrolysis & Mineral Integration

- What is the primary role of a muffle furnace in the annealing process of AlCrTiVNbx alloys? Enhance Alloy Strength

- What role does a muffle furnace play in analyzing the combustion residues? Optimize Your Composite Char Analysis