The essential electrical safety measures for a muffle furnace center on three core principles: proper grounding, the use of a dedicated and correctly rated power circuit, and having an accessible means to disconnect all power. These safeguards are non-negotiable as they protect operators from electric shock and the facility from fire by managing the high electrical loads and potential fault conditions inherent to high-temperature equipment.

Muffle furnaces combine high voltage with extreme temperatures, making electrical safety the foundational layer of all operational procedures. A failure in the electrical system not only poses a direct risk of shock and fire but can also trigger secondary thermal and mechanical failures.

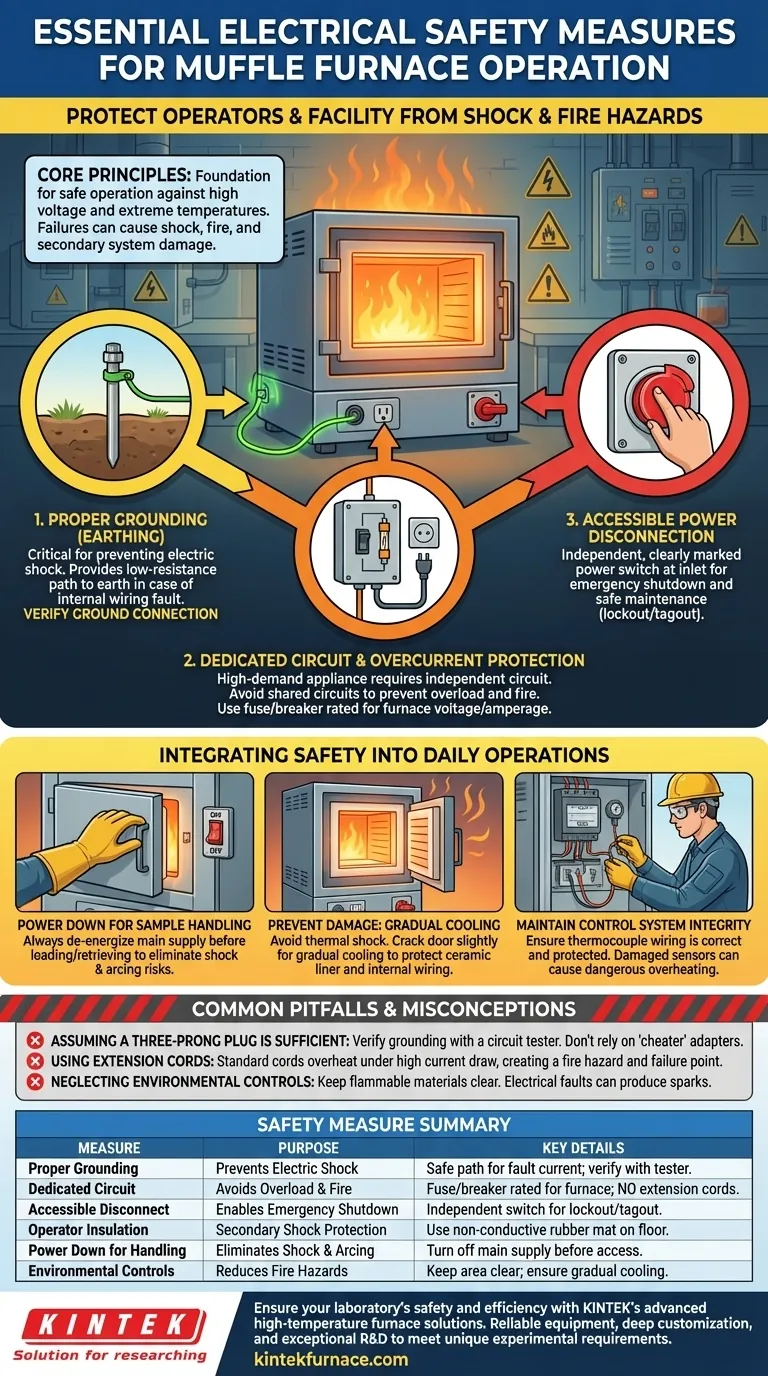

Foundational Electrical Safeguards

To operate a muffle furnace safely, the electrical installation must be treated with the same seriousness as the high temperatures it produces. These primary safeguards are the bedrock of protection.

The Critical Role of Grounding (Earthing)

Proper grounding is your single most important defense against electric shock. It provides a safe, low-resistance path for electrical current to flow to the earth in the event of an internal wiring fault.

Without a reliable ground connection, a fault could energize the entire metal chassis of the furnace. Anyone touching the unit would then become the path to ground, resulting in severe or fatal electrocution. Both the furnace and its external controller must be connected to a verified ground wire.

Dedicated Circuits and Overcurrent Protection

A muffle furnace is a high-demand appliance that should never share a circuit with other equipment. It must be powered by a dedicated circuit with a fuse or circuit breaker rated specifically for the furnace's voltage and amperage requirements.

Using a shared circuit or an improperly rated one can lead to overload, causing wires to overheat and creating a significant fire hazard. It can also cause voltage drops that impair the furnace's performance and damage its components.

Accessible Power Disconnection

An independent, clearly marked power switch must be installed at the power line inlet. This main disconnect allows you to cut all power to the unit in an emergency without having to fumble with the controller or unplug the unit.

This switch is also essential for performing maintenance safely, enabling a proper lockout/tagout procedure to ensure the furnace cannot be accidentally energized while being serviced.

Operator Insulation and Environment

As an additional layer of protection, a thick, non-conductive rubber mat should be placed on the floor in front of the furnace. This insulates the operator from the ground, providing secondary protection if a fault occurs and the primary grounding fails.

Integrating Electrical Safety into Daily Operations

Electrical safety isn't just about installation; it's woven into the fabric of how you use the furnace every day. Procedural discipline is key to preventing accidents.

Powering Down for Sample Handling

Always turn off the main power supply before loading or retrieving samples. This de-energizes the heating elements, eliminating the risk of electric shock from accidental contact and preventing arcing that could damage the furnace or ignite flammable materials.

Preventing Damage That Creates Electrical Hazards

The procedure for cooling the furnace is also a safety measure. Never open the furnace door fully immediately after a cycle. The resulting thermal shock can crack the ceramic furnace chamber.

A cracked liner could, over time, expose internal heating elements or wiring, creating a future electrical hazard that is not immediately obvious. Always crack the door slightly to allow for gradual cooling first.

Maintaining Control System Integrity

The thermocouple is the furnace's nerve center. Ensure its wiring is correctly installed—especially the positive and negative poles—and protected from physical damage.

An incorrectly wired or damaged thermocouple can send false temperature readings to the controller, leading to a dangerous overheating condition that presents a major fire risk.

Common Pitfalls and Misconceptions

Even with the best intentions, common oversights can undermine your safety protocol. Being aware of these pitfalls is critical for creating a truly safe environment.

Pitfall: Assuming a Three-Prong Plug Is Sufficient

Never assume a three-prong outlet is properly grounded, especially in older buildings. Use a circuit tester to verify that the outlet's ground connection is intact and functional. A "cheater" adapter or a faulty outlet provides a false sense of security.

Pitfall: Using Extension Cords

Do not use an extension cord to power a muffle furnace. Standard extension cords are not rated for the sustained high current draw, causing them to overheat and become a severe fire hazard. They also introduce another potential point of failure in the electrical connection.

Pitfall: Neglecting Environmental Controls

An electrical fault can easily produce sparks. Storing flammable or explosive materials anywhere near the furnace turns a minor electrical issue into a potential catastrophe. The area around the furnace must be kept clear of all combustible materials.

Finalizing Your Safety Protocol

Your specific safety actions should be guided by your primary operational goal. Use this framework to build a robust protocol for your lab or workshop.

- If your primary focus is preventing electric shock: Your protocol must mandate verified grounding, the use of an insulating floor mat, and a strict rule to de-energize the furnace before opening the door.

- If your primary focus is preventing fire: Prioritize the use of a dedicated, properly rated circuit, a ban on extension cords, and maintaining a clear, non-flammable workspace around the unit.

- If your primary focus is long-term reliability and safety: Enforce procedures for gradual cooling to protect the furnace liner, perform regular inspections of wiring and thermocouples, and never operate the unit beyond its maximum rated temperature.

By treating electrical safety as the foundation of your entire protocol, you ensure the protection of both your equipment and, more importantly, your personnel.

Summary Table:

| Safety Measure | Purpose | Key Details |

|---|---|---|

| Proper Grounding | Prevents electric shock | Provides safe path for fault current; verify with circuit tester |

| Dedicated Circuit | Avoids overload and fire | Use fuse/breaker rated for furnace; no extension cords |

| Accessible Power Disconnect | Enables emergency shutdown | Install independent switch for lockout/tagout |

| Operator Insulation | Secondary shock protection | Place non-conductive rubber mat in front of furnace |

| Power Down for Handling | Eliminates shock and arcing risks | Turn off main supply before loading/unloading samples |

| Environmental Controls | Reduces fire hazards | Keep area clear of flammable materials; ensure gradual cooling |

Ensure your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental requirements, minimizing risks and maximizing performance. Don't compromise on safety—contact us today to discuss how our solutions can protect your personnel and enhance your operations!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO