At its core, a combination dental furnace is distinguished by its dual-functionality. Unlike specialized units, it is engineered to perform both the high-temperature firing of layered ceramics and the pressure-based pressing of pressable ceramic ingots within a single, versatile machine.

The essential difference isn't just about features; it's a strategic choice between versatility and specialization. A combination furnace consolidates two critical laboratory processes, offering space and cost efficiency at the potential expense of workflow throughput.

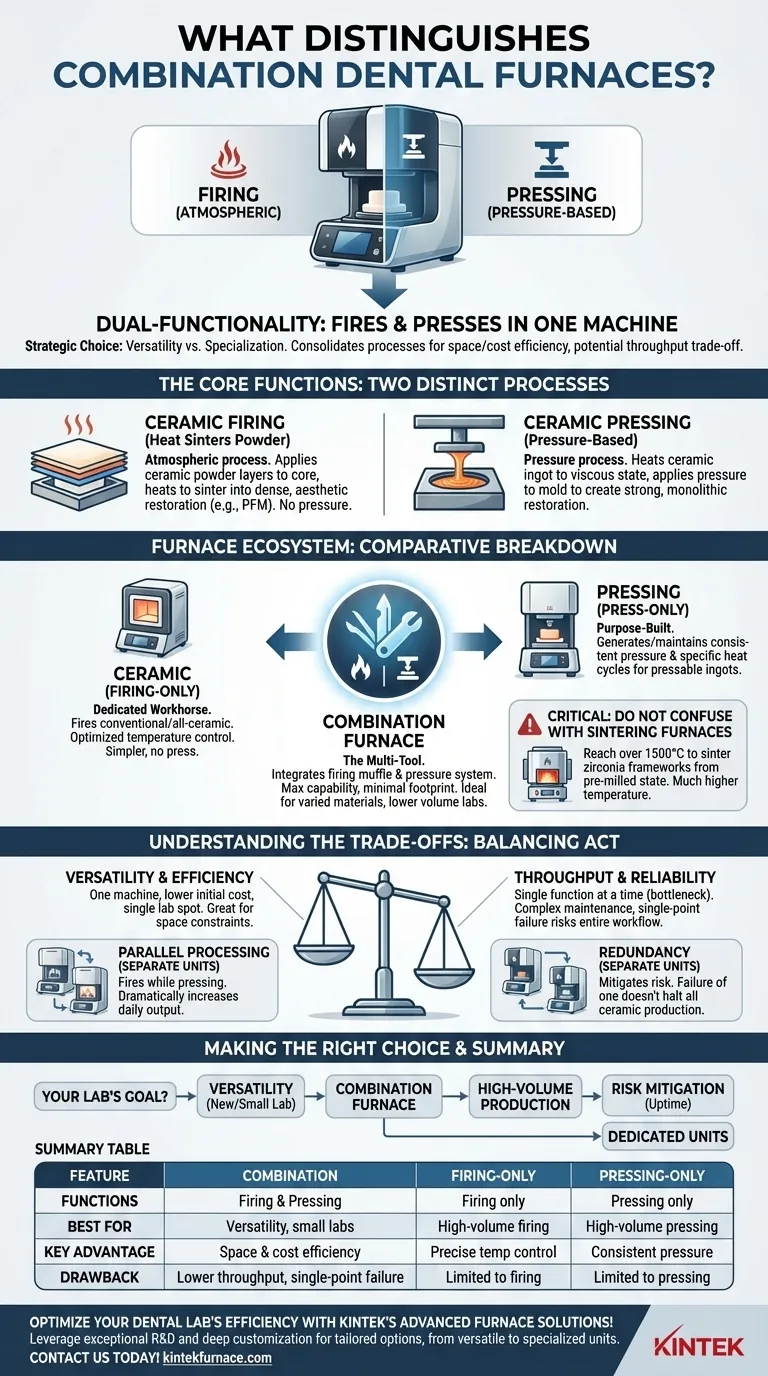

The Core Functions: Firing vs. Pressing

To understand the value of a combination furnace, you must first understand the two distinct processes it handles. These are fundamentally different operations requiring different environmental conditions.

Ceramic Firing

Ceramic firing is an atmospheric process. It involves applying layers of ceramic powder to a core material (like metal or zirconia) and heating it in the furnace.

The heat sinters the powder particles together, creating a dense, strong, and aesthetic porcelain restoration. This process does not require applied pressure.

Ceramic Pressing

Ceramic pressing is a pressure-based process. It starts with a wax pattern of the final restoration, which is then invested in a special material to create a mold.

A ceramic ingot is heated until it becomes viscous, and the furnace then applies pneumatic or mechanical pressure to "press" the molten ceramic into the mold. This creates a strong, monolithic restoration.

A Comparative Breakdown of Furnace Types

A combination furnace exists within an ecosystem of more specialized equipment. Understanding its counterparts clarifies its specific role.

The Combination Furnace

This is the multi-tool of dental furnaces. By integrating both a high-quality muffle for firing and a pressure system for pressing, it provides maximum capability in a minimal footprint. It is ideal for labs that work with a wide variety of materials but may not have the volume to justify dedicated units.

The Ceramic (Firing-Only) Furnace

This is a workhorse dedicated solely to firing conventional and all-ceramic restorations like PFMs and layered zirconia. Lacking a press mechanism, these units are often simpler and are optimized for the precise temperature control needed for glazing and staining.

The Pressing (Press-Only) Furnace

This furnace is purpose-built for one job: pressing ceramics. Its design is heavily focused on generating and maintaining consistent pressure and the specific heat cycles required by pressable ingot systems.

Specialized Sintering Furnaces

It is critical not to confuse these units with sintering furnaces. Sintering furnaces are designed to reach much higher temperatures (often over 1500°C) required to fully sinter zirconia frameworks from their chalky pre-milled state into a dense, high-strength final form.

Understanding the Trade-offs

Choosing a combination furnace involves balancing clear advantages against potential operational downsides.

Versatility vs. Throughput

A combination furnace can only perform one function at a time. A high-volume lab may create a significant bottleneck if technicians are waiting to either press or fire restorations.

Having separate, dedicated units allows for parallel processing—firing crowns while simultaneously pressing copings—dramatically increasing a lab's daily output.

Cost and Space Efficiency

This is the most significant advantage of a combination unit. The initial capital investment is lower than purchasing two separate machines, and it occupies only one spot on the lab bench. For new labs or those with space constraints, this is a powerful incentive.

Maintenance and Reliability

A single machine performing two distinct, demanding functions can be subject to more complex maintenance requirements. More critically, if a combination furnace requires servicing, the lab loses both its firing and pressing capabilities, potentially halting all ceramic production. Redundancy with separate units mitigates this risk.

Making the Right Choice for Your Lab

The decision to invest in a combination furnace versus specialized units should be driven entirely by your lab's specific operational goals and workflow.

- If your primary focus is versatility in a new or smaller lab: A combination furnace provides the most capability for the lowest initial cost and smallest footprint.

- If your primary focus is high-volume production: Dedicated, separate firing and pressing furnaces are essential to prevent bottlenecks and maximize throughput.

- If your primary focus is risk mitigation and operational uptime: Two separate units provide crucial redundancy, ensuring that the failure of one machine does not stop your entire ceramic workflow.

Understanding these core distinctions empowers you to invest in the equipment that truly aligns with your laboratory's workflow and business goals.

Summary Table:

| Feature | Combination Furnace | Ceramic (Firing-Only) Furnace | Pressing (Press-Only) Furnace |

|---|---|---|---|

| Functions | Firing & Pressing | Firing only | Pressing only |

| Best For | Versatility, small labs | High-volume firing | High-volume pressing |

| Key Advantage | Space & cost efficiency | Precise temperature control | Consistent pressure application |

| Potential Drawback | Lower throughput, single-point failure | Limited to firing | Limited to pressing |

Optimize your dental lab's efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace options, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental and production needs, whether you require versatile combination furnaces or specialized units for high-volume workflows. Contact us today to discuss how our solutions can enhance your lab's performance and reliability!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency