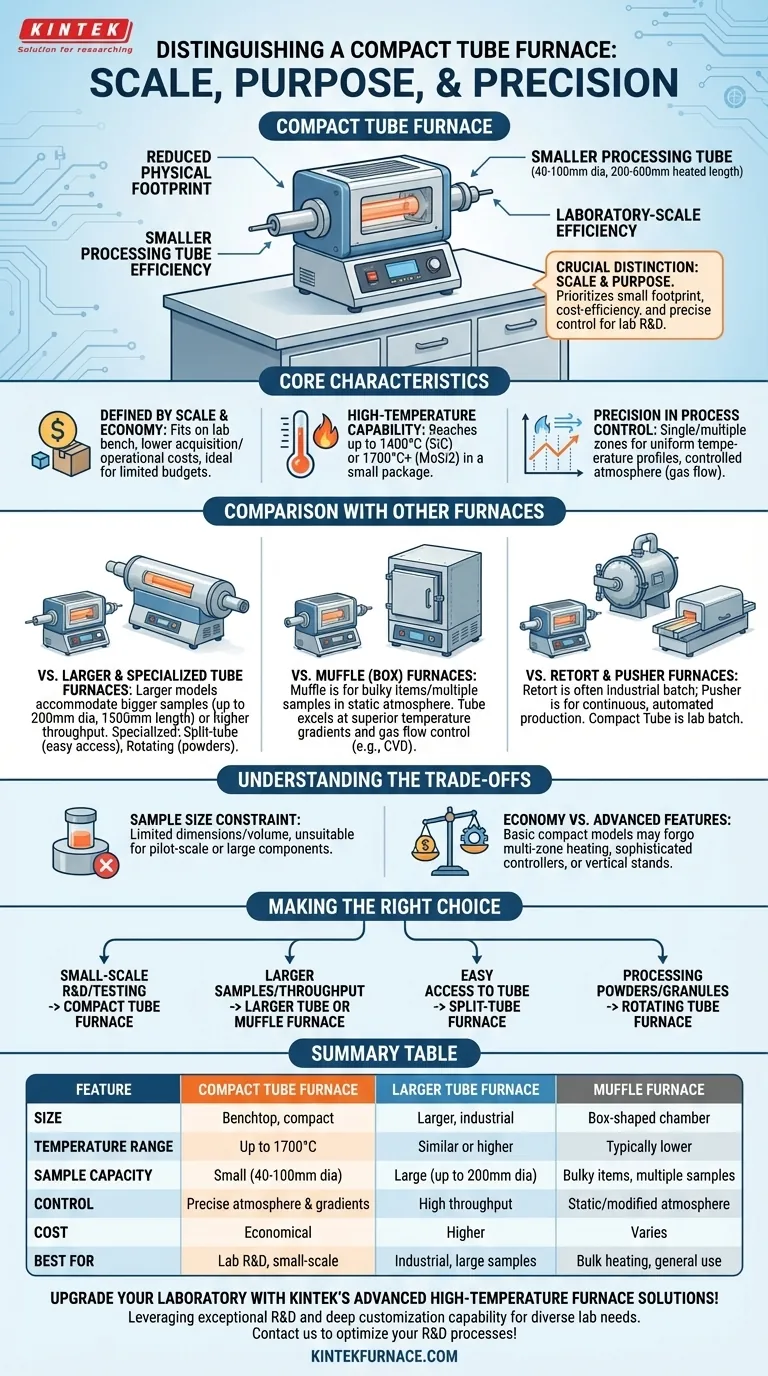

At its core, a compact tube furnace is a smaller, more economical version of a standard tube furnace, specifically designed for benchtop use in laboratory settings. While it shares the fundamental design of heating a cylindrical tube, its defining characteristics are its reduced physical footprint, smaller processing tube dimensions (typically 40-100mm diameter and 200-600mm heated length), and emphasis on efficiency for smaller-scale applications.

The crucial distinction is scale and purpose. A compact tube furnace prioritizes a small footprint, cost-efficiency, and precise control for laboratory-scale research and development, whereas other furnace types are built for larger samples, different heating geometries, or industrial-scale continuous processing.

Core Characteristics of a Compact Tube Furnace

A compact tube furnace is not a lesser version of a larger furnace, but rather a specialized tool designed for a specific work environment. Its features are optimized for the constraints and needs of a modern lab.

Defined by Scale and Economy

The term "compact" directly refers to the furnace's physical size. These units are built to fit on a lab bench, minimizing the space they occupy.

This smaller scale often translates to lower acquisition and operational costs, making them an economical choice for universities, startups, or research groups with limited budgets.

High-Temperature Capability in a Small Package

Despite their size, compact tube furnaces are capable of reaching very high temperatures. They often use high-purity alumina tubes and advanced heating elements.

Models with silicon carbide (SiC) elements can typically reach up to 1400°C, while those with molybdenum disilicide (MoSi2) elements can achieve 1700°C or more, rivaling the capabilities of much larger systems.

Precision in Process Control

A key advantage of the tube furnace design, which compact models retain, is the ability to maintain precise control over the sample environment.

They can be configured with single or multiple heated zones (e.g., one, two, or three zones) to create a highly uniform temperature profile across the sample length. This design is also ideal for controlling the atmosphere by flowing specific gases through the tube.

How Compact Models Compare to Other Furnaces

Understanding the compact tube furnace requires comparing it not only to its larger relatives but also to fundamentally different furnace designs.

vs. Larger & Specialized Tube Furnaces

The primary difference between a "compact" and a "standard" tube furnace is sample capacity. Larger models feature heated lengths up to 1500mm and diameters up to 200mm to accommodate bigger samples or higher throughput.

Other specialized tube furnaces offer functional advantages. Split-tube furnaces can be opened in the middle, allowing for easy placement of the process tube, which is useful if the tube has complex fixtures on its ends. Rotating tube furnaces are designed to tumble powders and granules during heating to ensure uniform processing.

vs. Muffle (Box) Furnaces

This is a critical distinction. A muffle furnace heats a box-shaped chamber, making it suitable for heating bulky items or multiple samples at once in a static air or modified atmosphere environment.

A tube furnace, by contrast, is designed for superior control over temperature gradients and gas flow. Its tubular geometry is perfect for processes like chemical vapor deposition (CVD), annealing, or purification where a controlled atmosphere must flow directly over the sample.

vs. Retort and Pusher Furnaces

A retort furnace also uses a sealed chamber (the "retort") for controlled atmosphere processing, making it functionally similar to a tube furnace but often on a larger, more industrial scale. A tube furnace can be considered a specific type of retort furnace.

A pusher furnace is designed for continuous, automated production. Materials are "pushed" through the heating zones, unlike the batch processing typical of a laboratory compact tube furnace.

Understanding the Trade-offs

Choosing a compact tube furnace involves balancing its benefits against its inherent limitations.

The Constraint of Sample Size

The most obvious trade-off is size. The smaller tube diameter and length strictly limit the dimensions and volume of the material you can process. This makes it unsuitable for pilot-scale production or large component testing.

Economy vs. Advanced Features

While cost-effective, the most basic "economy" compact models may forgo features found on more advanced systems. This can include multi-zone heating for perfect temperature uniformity, sophisticated temperature controllers, or integrated stands for vertical operation.

Uniformity Over Length

Achieving a long, highly uniform hot zone is a function of the furnace's heated length and its number of heating zones. While a compact furnace can have three zones, the absolute length of that uniform zone will be shorter than what is achievable in a larger furnace designed for that purpose.

Making the Right Choice for Your Application

Selecting the correct thermal processing equipment depends entirely on your specific goals.

- If your primary focus is small-scale R&D or materials testing: A compact tube furnace provides an excellent balance of precise atmospheric and thermal control, high-temperature capability, and cost-effectiveness.

- If your primary focus is processing larger samples or higher throughput: A larger standard tube furnace or a muffle/box furnace is the necessary choice.

- If your primary focus is easy access to the process tube: A split-tube furnace offers convenience that a standard compact model cannot match.

- If your primary focus is processing powders or granules evenly: A rotating tube furnace is the specialized tool designed for this exact task.

Ultimately, a compact tube furnace is the definitive choice when precision and control must be achieved within the spatial and budgetary constraints of a laboratory environment.

Summary Table:

| Feature | Compact Tube Furnace | Larger Tube Furnace | Muffle Furnace |

|---|---|---|---|

| Size | Benchtop, compact | Larger, industrial | Box-shaped chamber |

| Temperature Range | Up to 1700°C | Similar or higher | Typically lower |

| Sample Capacity | Small (40-100mm dia) | Large (up to 200mm dia) | Bulky items, multiple samples |

| Control | Precise atmosphere & gradients | High throughput | Static/modified atmosphere |

| Cost | Economical | Higher | Varies |

| Best For | Lab R&D, small-scale | Industrial, large samples | Bulk heating, general use |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, enhancing efficiency and results. Contact us today to discuss how our compact tube furnaces can optimize your R&D processes!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the future trends in CVD technology? AI, Sustainability, and Advanced Materials

- What forms of energy can be applied in CVD to initiate chemical reactions? Explore Heat, Plasma, and Light for Optimal Thin Films

- How does a CVD system ensure the quality of carbon layers? Achieving Nanometer Precision with KINTEK

- What is the role of temperature in PECVD? Optimize Film Quality and Substrate Protection

- What is resistance heating and how is it classified? Discover the Best Method for Your Thermal Needs