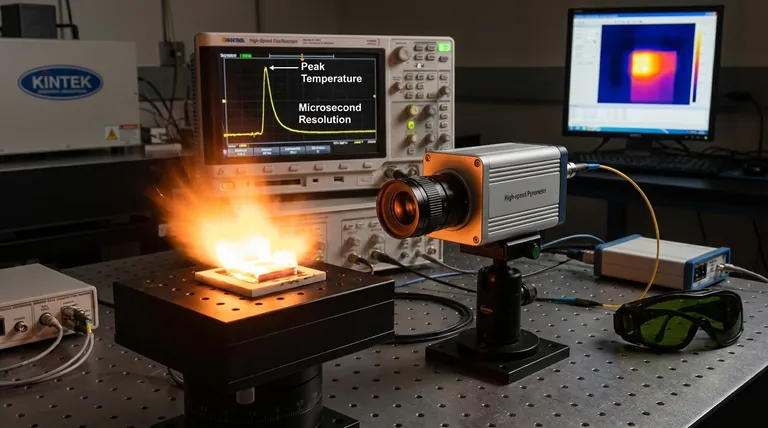

A high-speed pyrometer acts as a temporal microscope for thermal events. It provides critical microsecond-level time resolution to capture instantaneous temperature changes and peak reaction heat during self-propagating reactions. This data is essential for analyzing how substrate structures absorb heat and for correlating the density of the film structure with its overall thermal performance.

By isolating peak temperatures at microsecond intervals, high-speed pyrometry moves beyond simple heat measurement. It reveals the dynamic relationship between a film's structural density and the heat sink effects of its substrate, allowing for precise optimization of reactive properties.

Unlocking Reaction Dynamics

To evaluate reactive multilayer films effectively, you must see what happens during the briefest moments of ignition and propagation.

Microsecond-Level Resolution

Standard thermal sensors are often too slow to catch the nuances of a self-propagating reaction. A high-speed pyrometer offers microsecond-level time resolution. This allows researchers to monitor temperature changes the instant they occur, preventing the loss of critical transient data.

Capturing Peak Temperatures

The most vital data point in these evaluations is the peak reaction temperature. The pyrometer captures this maximum value accurately. Knowing the true peak is necessary to calculate the energy potential and efficiency of the reaction.

Evaluating Environmental Interactions

The performance of a reactive film is not just about the film itself; it is about how the film interacts with its environment, specifically the substrate.

Quantifying the Heat Sink Effect

A major factor in performance degradation is the heat sink effect of the microstructured substrate. The pyrometer provides the data needed to evaluate how much thermal energy is being drained away from the reaction by the underlying material.

Assessing Thermal Loss

By monitoring the temperature profile, you can measure the impact of the microstructure on thermal loss. This helps identify if the substrate geometry is aiding the reaction or suffocating it by drawing away too much heat.

Correlating Structure and Performance

The physical architecture of the film directly dictates its thermal output.

Linking Density to Heat

The pyrometer allows you to determine the correlation between structural density and reaction temperature. By comparing peak temperature data against films of different densities, you can identify the optimal structural configuration for maximum energy release.

Understanding the Limitations

While high-speed pyrometry is a powerful tool, it is important to recognize its operational boundaries to ensure data accuracy.

Optical Dependencies

Pyrometers are optical instruments that rely on detecting infrared radiation. They require a clear line of sight to the reaction zone, which can be challenging depending on the experimental setup or if the reaction produces significant smoke or debris.

Surface vs. Volumetric Measurement

These devices typically measure surface temperature. While this correlates strongly with overall performance, it may not perfectly represent the internal temperature deep within a thick multilayer stack, potentially skewing data regarding total heat generation.

Making the Right Choice for Your Goal

How you interpret the pyrometer data depends on which aspect of the multilayer film you are trying to optimize.

- If your primary focus is substrate design: Analyze the thermal loss data to minimize the heat sink effect of your microstructures.

- If your primary focus is reaction efficiency: Use the peak temperature data to find the optimal structural density that maximizes heat generation.

High-speed pyrometry transforms rapid thermal flashes into actionable data, providing the insight needed to bridge the gap between material structure and reactive performance.

Summary Table:

| Feature | Critical Information Provided | Impact on Performance Evaluation |

|---|---|---|

| Microsecond Resolution | Real-time temperature transients | Captures peak reactions without data loss. |

| Peak Temperature | Maximum thermal energy output | Calculates energy potential and efficiency. |

| Heat Sink Analysis | Substrate-induced thermal loss | Quantifies how environment affects reaction. |

| Density Correlation | Structural density vs. heat output | Identifies optimal configuration for energy release. |

| Optical Detection | Surface-level infrared radiation | Provides non-contact, high-speed thermal profiling. |

Maximize Your Material Research with KINTEK

Precision thermal analysis is only the beginning. At KINTEK, we specialize in the equipment necessary to develop and test high-performance materials. Backed by expert R&D and world-class manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other specialized lab high-temperature furnaces—all fully customizable to meet your unique research requirements.

Ready to bridge the gap between material structure and reactive performance? Contact us today to discuss how our advanced laboratory solutions can empower your next breakthrough.

References

- Konrad Jaekel, Heike Bartsch. Influence of Increasing Density of Microstructures on the Self‐Propagating Reaction of Al/Ni Reactive Nanoscale Multilayers. DOI: 10.1002/adem.202302225

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

People Also Ask

- How does the operating atmosphere affect MoSi2 heating elements? Maximize Temperature & Lifespan

- How does the protective layer form on Nickel-Chromium heating elements? Unlock the Secret to Long-Lasting Performance

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What are the advantages of MoSi2 heating elements in terms of temperature capability? Unmatched High-Temp Performance

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What are some common types of MoSi2 heating elements and accessories? Discover Shapes, Grades, and Benefits

- How does advanced power control extend heating element lifespan? Boost Efficiency and Cut Costs

- What is resistance heating and how is it classified? Discover the Best Method for Your Thermal Needs