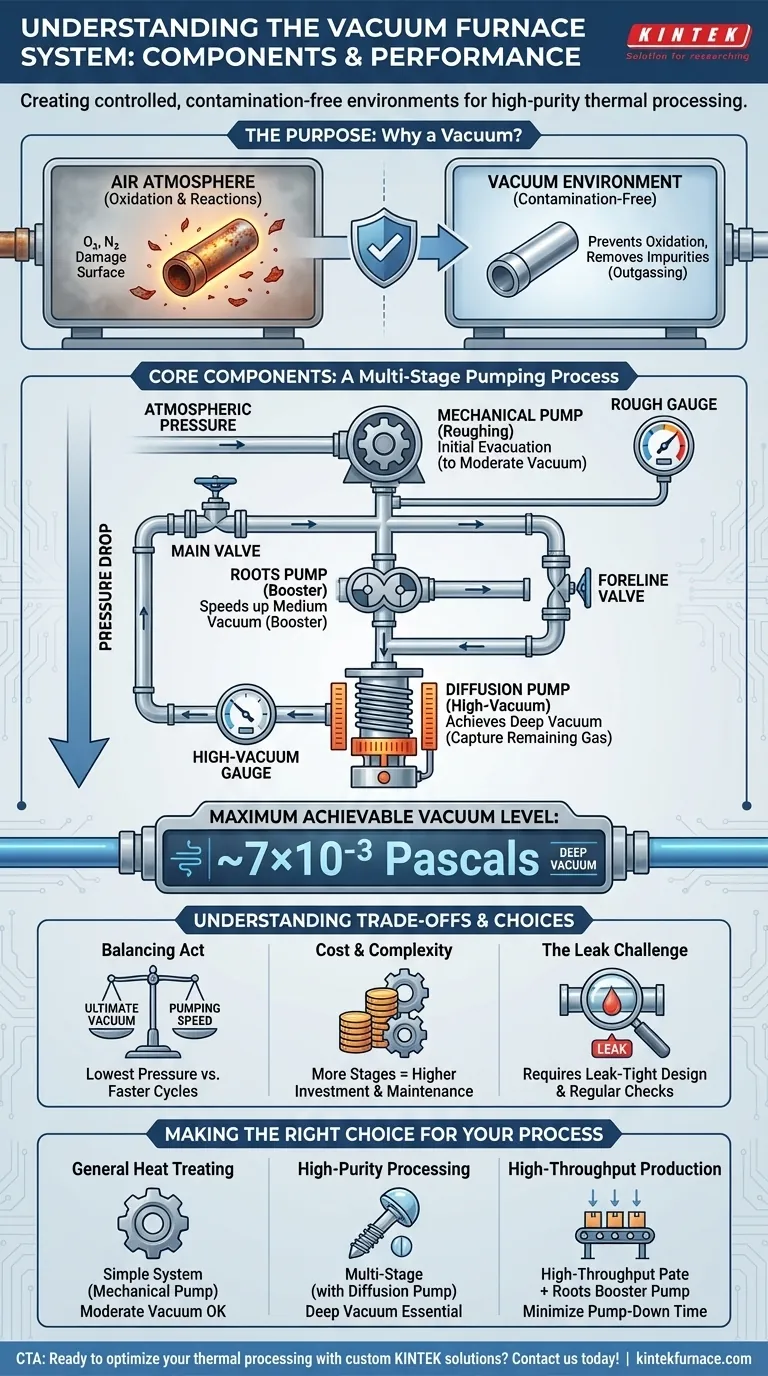

At its core, a vacuum furnace's vacuum system is an assembly of pumps, valves, and gauges designed to remove atmosphere from a sealed chamber. The primary components are vacuum pumps (often in multiple stages, such as mechanical, Roots, and diffusion pumps), vacuum valves for isolation and control, and vacuum gauges for measurement. With a properly configured system, a maximum vacuum level of approximately 7×10⁻³ Pascals can be achieved.

The critical insight is that a vacuum system is not a single part, but a carefully orchestrated sequence of components. Each component performs a specific function at a different pressure range, working together to efficiently create the ultra-low-pressure environment required for high-purity thermal processing.

The Purpose of the Vacuum System

A vacuum furnace's defining feature is its ability to heat materials without the interference of air. The vacuum system is the component responsible for creating this controlled, contamination-free environment.

Preventing Oxidation and Reactions

At high temperatures, most metals will rapidly oxidize or react with the gases present in air, primarily oxygen and nitrogen. By removing these gases, the vacuum system ensures the material's surface finish and chemical purity remain intact during processes like brazing, sintering, or annealing.

Removing Impurities

The vacuum environment also helps to draw out trapped gases and other volatile impurities from within the material itself, a process known as outgassing. This results in a cleaner, higher-quality final product.

Deconstructing the Core Components

The vacuum system operates in stages, with different components optimized for different pressure regimes. This multi-stage approach is the key to achieving a high vacuum efficiently.

The Pumping System: A Multi-Stage Process

No single pump can efficiently move gas from atmospheric pressure down to a deep vacuum. Therefore, a combination is used.

- Mechanical Pumps (Roughing Pumps): These are the workhorses that perform the initial evacuation, or "roughing," of the furnace chamber. They remove the vast majority of air, taking the pressure from atmospheric down to a moderate vacuum level.

- Roots Pumps (Boosters): A Roots pump is often placed between the mechanical pump and the high-vacuum pump. It cannot pump directly to the atmosphere, but it acts as a booster to speed up evacuation in the medium vacuum range, significantly reducing overall cycle time.

- Diffusion Pumps (High-Vacuum Pumps): Once the mechanical and booster pumps have lowered the pressure sufficiently, the diffusion pump takes over. This type of pump uses jets of hot oil vapor to capture remaining gas molecules and achieve the final, deep vacuum level required for high-purity applications.

Vacuum Valves: Controlling Flow and Isolation

Valves are the gatekeepers of the vacuum system. They allow an operator to isolate different parts of the system, which is critical for process control. For example, a main valve isolates the chamber from the pumps, while a foreline valve isolates the diffusion pump from the mechanical pump.

Vacuum Gauges: Measuring the Invisible

You cannot control what you cannot measure. The vacuum system uses multiple types of gauges, as each is designed to work accurately within a specific pressure range. A system will typically have a "rough" gauge to monitor the initial pump-down and a separate high-vacuum gauge to measure the final pressure inside the chamber.

Understanding the Trade-offs

Selecting or designing a vacuum system involves balancing performance, cost, and process requirements.

Ultimate Vacuum vs. Pumping Speed

Achieving the lowest possible pressure (ultimate vacuum) is not the only goal. The pumping speed, or how quickly the system can evacuate the chamber, is equally important for production efficiency. Larger pumps or the addition of a Roots booster can dramatically decrease cycle times but increase cost and complexity.

Cost and Complexity

A simple system with only a mechanical pump is relatively inexpensive but limited to a rough vacuum. Adding Roots and diffusion pumps to achieve a high vacuum significantly increases the initial investment, maintenance requirements, and operational complexity.

The Constant Battle Against Leaks

A vacuum system is only as strong as its weakest point. Even microscopic leaks in welds, seals, or fittings can prevent the system from reaching its target vacuum level. Proper design, high-quality components, and regular maintenance are essential to ensure a leak-tight system.

Making the Right Choice for Your Process

The ideal vacuum system configuration depends entirely on the material being processed and the desired outcome.

- If your primary focus is general heat treating (e.g., hardening, tempering): A simpler system with a mechanical pump may be sufficient, as a moderate vacuum is often enough to prevent significant oxidation.

- If your primary focus is high-purity processing (e.g., brazing, medical implants, aerospace alloys): A multi-stage system with a diffusion pump is necessary to achieve the deep vacuum required to prevent any contamination.

- If your primary focus is high-throughput production: Investing in a Roots booster pump is crucial to minimize pump-down time and maximize the number of cycles you can run per day.

Ultimately, an effective vacuum system is a balanced solution that matches the right pumping technology to the specific purity and throughput demands of your thermal process.

Summary Table:

| Component Type | Function | Key Examples |

|---|---|---|

| Vacuum Pumps | Remove gases in stages | Mechanical, Roots, Diffusion Pumps |

| Vacuum Valves | Control and isolate flow | Main Valve, Foreline Valve |

| Vacuum Gauges | Measure pressure levels | Rough Gauge, High-Vacuum Gauge |

| Vacuum Level | Maximum achievable | ~7×10⁻³ Pascals |

Ready to optimize your thermal processing with a custom vacuum furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs—whether for high-purity applications or high-throughput production. Contact us today to discuss how our tailored furnace systems can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance