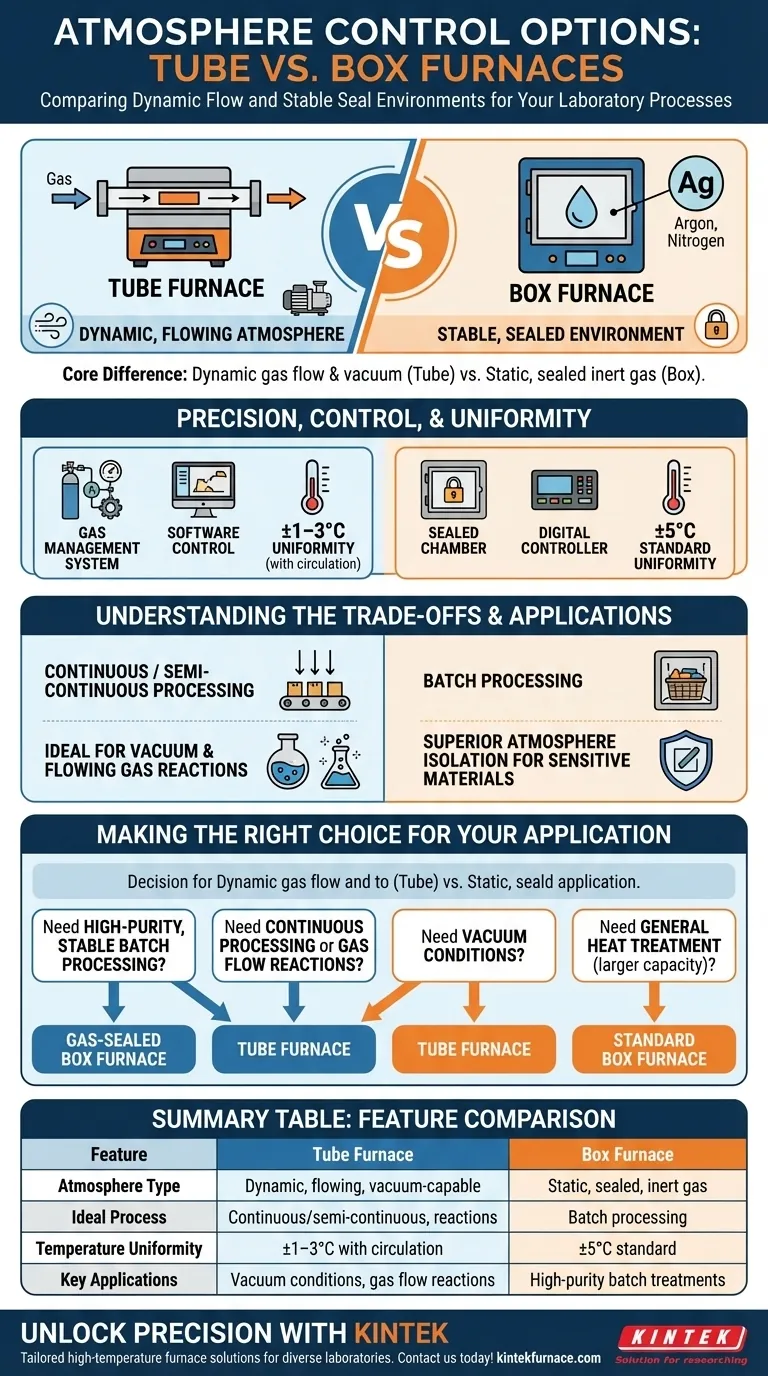

At its core, the primary difference in atmosphere control is how the environment is contained. Tube furnaces excel at creating dynamic, flowing atmospheres and vacuum conditions, while box furnaces specialize in providing stable, gas-sealed inert atmospheres for batch processing. Both systems are designed to protect materials from oxidation and contamination but achieve it through fundamentally different mechanical designs.

Your choice between a tube and box furnace hinges on a single question: does your process require a flowing atmosphere (or vacuum), or a static, sealed one? The furnace's physical design—a pass-through tube versus a sealed chamber—dictates its atmospheric capabilities and ideal applications.

Flow vs. Static Seal: The Fundamental Divide

The most critical distinction in atmosphere control is not the type of gas used, but how the furnace contains and manages that gas. This mechanical difference dictates the furnace's ideal use case.

Tube Furnaces: A Dynamic, Flowing Atmosphere

A tube furnace uses a process tube as the chamber. Gas is introduced at one end and flows through the tube, exiting at the other. This creates a dynamic, circulating atmosphere.

This design is essential for processes that require continuous gas replenishment or for facilitating chemical reactions where byproducts must be carried away.

Furthermore, the geometry of a tube is naturally suited for being sealed at both ends and evacuated. This makes tube furnaces the standard choice for applications requiring vacuum conditions to prevent any oxidation or contamination.

Box Furnaces: A Stable, Sealed Environment

A box furnace uses a larger, sealed chamber. An inert gas like argon or nitrogen is used to purge the ambient air and then fill the chamber, which is then sealed to isolate the internal environment.

The result is a stable, static atmosphere. The gas does not actively flow through the chamber during operation.

This method is ideal for batch processing, where materials are placed inside, treated for a set duration in a highly stable and predictable inert environment, and then removed.

Precision, Control, and Uniformity

Beyond the core design, the level of control you can achieve varies, impacting process repeatability and material quality.

Gas Management and Software Control

Modern furnaces utilize advanced control systems. Options include dedicated gas management systems (like SIMGAS4) that precisely regulate gas mixtures and flow rates.

Additionally, Data Acquisition and Control Software (DACS) allows users to program complex temperature and atmosphere profiles, enabling remote operation and precise process automation for both furnace types.

Temperature Uniformity and Accuracy

Atmosphere control directly impacts temperature uniformity. Specialized atmosphere furnaces, often tube-style, feature gas circulation systems that improve heat distribution, achieving a tight temperature accuracy of ±1–3°C.

Standard box furnaces, while robust, generally offer a wider control window of ±5°C. This is perfectly suitable for many heat treatments but may be insufficient for processes requiring extremely precise thermal stability.

Understanding the Trade-offs

Choosing the right furnace requires balancing the needs of your material, your process, and your operational constraints.

Process Type: Continuous vs. Batch

A tube furnace's flow-through design makes it ideal for continuous or semi-continuous processing, where materials are passed through the hot zone.

A box furnace is designed exclusively for batch processing, where a finite quantity of material is treated in a single, static cycle.

Atmosphere Purity and Isolation

While both protect from oxidation, a gas-sealed box furnace offers superior isolation from the external environment. Its static, sealed nature minimizes the risk of contamination, which is critical for highly sensitive materials.

Tube furnaces can be more susceptible to atmosphere leakage at the entry and exit points unless high-quality seals or vacuum conditions are used.

Operational Demands

Operating any controlled-atmosphere furnace requires diligence. You must maintain proper gas purity, continuously monitor temperature and pressure, and follow strict safety protocols. Regular equipment maintenance is non-negotiable for ensuring both process quality and operator safety.

Making the Right Choice for Your Application

Your final decision should be guided by your primary process goal.

- If your primary focus is a high-purity, stable environment for batch processing: A gas-sealed box furnace is the superior choice for its excellent atmospheric isolation.

- If your primary focus is continuous processing or reactions requiring gas flow: A tube furnace is specifically designed for creating a dynamic, flowing atmosphere.

- If your primary focus is performing work under vacuum conditions: A tube furnace is the standard and most direct solution due to its easily sealed geometry.

- If your primary focus is general heat treatment with a larger capacity: A standard box furnace provides simplicity and volume for processes where atmosphere control is less stringent.

Understanding these fundamental differences in atmosphere control empowers you to select the furnace that aligns precisely with your material and process requirements.

Summary Table:

| Feature | Tube Furnace | Box Furnace |

|---|---|---|

| Atmosphere Type | Dynamic, flowing, vacuum-capable | Static, sealed, inert gas |

| Ideal Process | Continuous/semi-continuous, reactions | Batch processing |

| Temperature Uniformity | ±1–3°C with circulation | ±5°C standard |

| Key Applications | Vacuum conditions, gas flow reactions | High-purity batch treatments |

Unlock Precision in Your Laboratory Processes with KINTEK

Struggling to choose the right furnace for your specific atmosphere control needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements—whether you need dynamic gas flow, vacuum environments, or stable batch processing.

Let us help you enhance efficiency, ensure material purity, and achieve superior results. Contact us today to discuss your project and discover how our expertise can drive your success!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing