In short, porcelain furnaces are used in the chemical industry for highly specialized, high-temperature processes where corrosion resistance is paramount. Their primary applications include breaking down hazardous pollutants in flue gas treatment and creating advanced materials through chemical vapor deposition (CVD).

The true value of porcelain in industrial chemistry isn't the furnace itself, but the material's unique ability to remain stable and non-reactive at extreme temperatures and in the presence of highly corrosive substances, which would destroy conventional metal equipment.

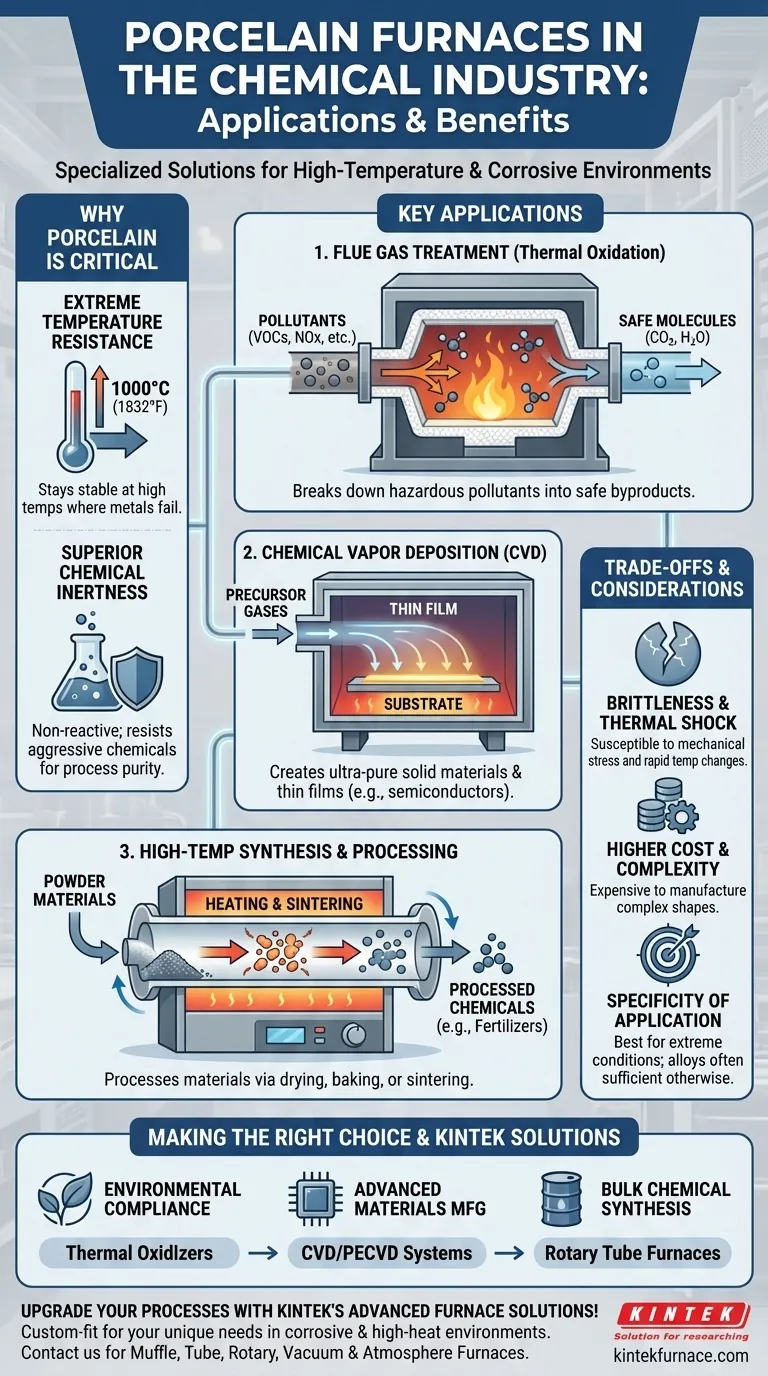

Why Porcelain is a Critical Material

Before looking at specific applications, it's essential to understand why porcelain and other high-performance ceramics are chosen for these demanding environments. Standard metal furnaces fail under these conditions.

Extreme Temperature Resistance

Many valuable chemical reactions and decomposition processes only occur at very high temperatures, often exceeding 1000°C (1832°F). Porcelain maintains its structural integrity and stability at these temperatures, where many metals would weaken or melt.

Superior Chemical Inertness

This is the most critical property. Industrial exhaust gases (flue gas) and chemical precursors for CVD are often intensely corrosive. Porcelain is a ceramic, which is chemically inert and does not react with these aggressive chemicals, ensuring process purity and preventing the furnace itself from being destroyed.

Key Applications in the Chemical Industry

The unique properties of porcelain enable several niche but vital industrial processes that would otherwise be impractical.

Flue Gas Treatment and Pollution Control

Many industrial processes release harmful pollutants like volatile organic compounds (VOCs), nitrogen oxides (NOx), and other hazardous air pollutants.

A porcelain-lined furnace acts as a thermal oxidizer. The contaminated gas is channeled into the furnace and heated to extreme temperatures, causing the harmful compounds to break down into safer molecules like carbon dioxide and water. The porcelain lining is essential to withstand the corrosive nature of the flue gas.

Chemical Vapor Deposition (CVD)

CVD is a process used to create ultra-pure, high-performance solid materials and thin films, such as those used in the semiconductor industry.

In this process, precursor gases are introduced into a furnace where they react or decompose on a heated surface (substrate) to form a solid deposit. A furnace with a porcelain or quartz interior provides the clean, controlled, and non-reactive high-temperature environment needed for the high-purity coatings to form without contamination.

High-Temperature Synthesis and Processing

Certain industrial chemicals and materials require high-temperature processing steps like drying, baking, or sintering (fusing powders together with heat).

For example, specialized rotary tube furnaces, often lined with ceramics, are used in fertilizer manufacturing to produce chemicals like potassium nitride. The rotating chamber ensures materials are heated evenly, while the ceramic lining prevents reactions with the product.

Understanding the Trade-offs

While invaluable, porcelain and ceramic-lined furnaces are not a universal solution. They have specific limitations that engineers must consider.

Brittleness and Thermal Shock

Unlike metals, ceramics are brittle and can crack under mechanical stress. They are also susceptible to thermal shock—cracking caused by rapid changes in temperature. This necessitates carefully controlled heating and cooling cycles.

Higher Cost and Manufacturing Complexity

High-purity ceramic components are generally more expensive to manufacture than their metal alloy counterparts. Creating complex shapes can also be more difficult and costly, which may influence furnace design.

Specificity of Application

For the vast majority of chemical heating processes that do not involve extreme temperatures or highly corrosive substances, furnaces made from stainless steel or other high-performance alloys remain the more practical and cost-effective choice.

Making the Right Choice for Your Goal

Selecting the right furnace technology depends entirely on the chemical process you need to execute.

- If your primary focus is environmental compliance: A porcelain-lined thermal oxidizer is a key technology for the thermal abatement of corrosive and hazardous flue gases.

- If your primary focus is advanced materials manufacturing: The inert, high-temperature environment of a porcelain or quartz furnace is essential for purity-sensitive processes like Chemical Vapor Deposition.

- If your primary focus is bulk chemical synthesis: Ceramic-lined rotary furnaces are a vital tool for the continuous, high-temperature processing of certain powders and granular materials.

Ultimately, the use of porcelain in chemical furnaces is a perfect example of leveraging a specific material's properties to solve problems that are impossible to tackle with conventional means.

Summary Table:

| Application | Key Use | Key Property |

|---|---|---|

| Flue Gas Treatment | Thermal oxidation of pollutants | Chemical inertness |

| Chemical Vapor Deposition (CVD) | Creating high-purity materials | High-temperature stability |

| High-Temperature Synthesis | Sintering and processing chemicals | Durability in extreme heat |

Upgrade your chemical processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, enhancing efficiency and reliability in corrosive or high-heat environments. Contact us today to discuss how we can support your goals in pollution control, materials manufacturing, or chemical synthesis!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure