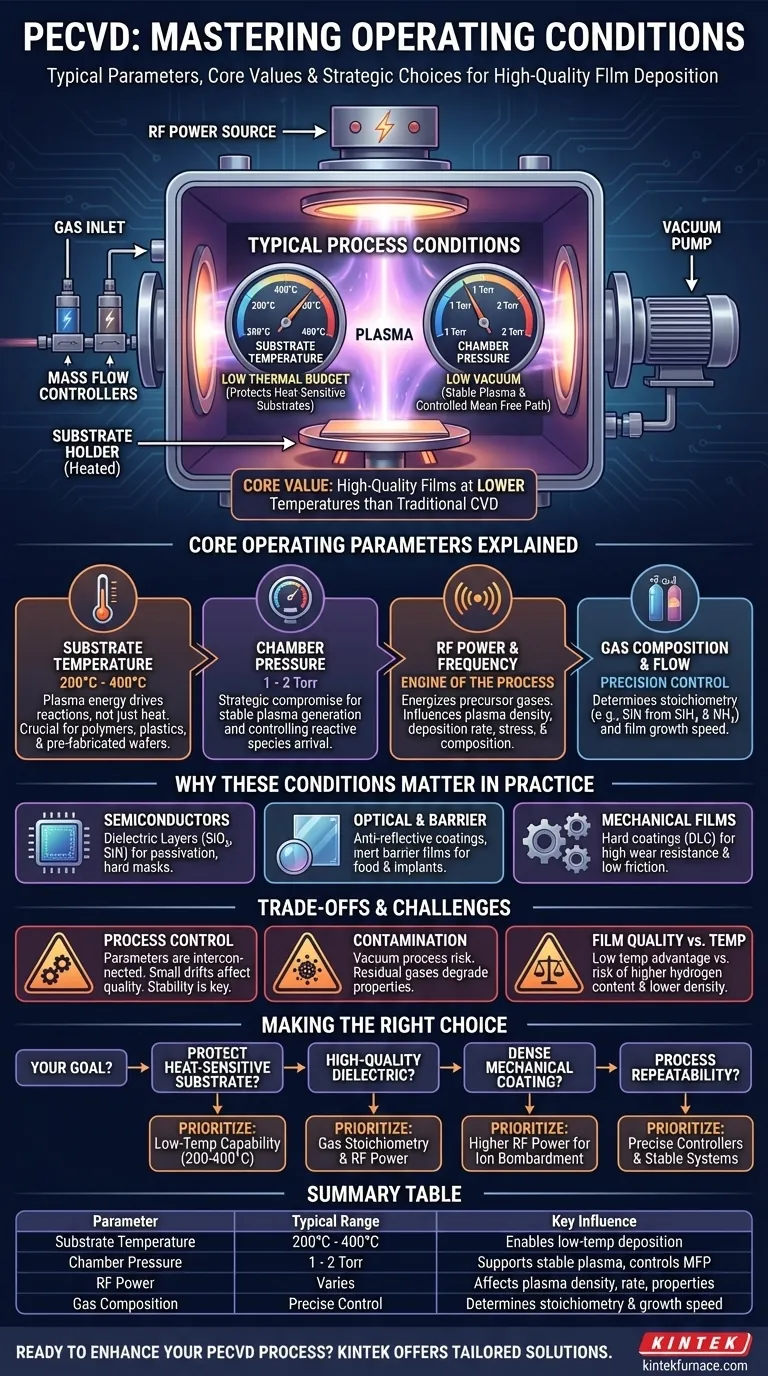

In a typical process, Plasma-Enhanced Chemical Vapor Deposition (PECVD) operates at a substrate temperature between 200°C and 400°C and within a low vacuum pressure range of 1 to 2 Torr. While these are the standard parameters, the process is highly adaptable, with both lower and higher temperature variations used for specific applications.

The core value of PECVD is not its specific operating range, but its ability to deposit high-quality films at significantly lower temperatures than traditional Chemical Vapor Deposition (CVD). Understanding the interplay between temperature, pressure, and plasma power is the key to mastering the process.

The Core Operating Parameters Explained

The conditions within a PECVD chamber are not arbitrary; each parameter is a lever that controls a specific aspect of the deposition process and the final properties of the deposited film.

Substrate Temperature (200°C - 400°C)

The defining feature of PECVD is its relatively low operating temperature. This is enabled by using energy from a plasma, rather than purely thermal energy, to drive the chemical reactions.

This lower thermal budget is critical when depositing films on substrates that cannot withstand high heat, such as polymers, plastics, or semiconductor wafers that have already undergone previous fabrication steps. The temperature is precisely controlled, often by heating the electrode on which the substrate sits.

Chamber Pressure (1 - 2 Torr)

PECVD operates in a low-vacuum environment. This pressure range is a strategic compromise.

It must be low enough to allow the generation of a stable plasma, a state of ionized gas. It is also crucial for controlling the mean free path—the average distance molecules travel before colliding—which influences how reactive species arrive at the substrate surface.

RF Power and Frequency

While not a temperature or pressure, Radio Frequency (RF) power is the engine of the PECVD process. An RF source energizes the precursor gases, creating the plasma.

The amount of power applied directly influences the plasma density and ion energy. This, in turn, affects the film's deposition rate, internal stress, density, and chemical composition.

Gas Composition and Flow Rate

The actual film is built from precursor gases introduced into the chamber through precision mass-flow-controlled lines. For example, depositing silicon nitride (SiN) might involve a mixture of silane (SiH₄) and ammonia (NH₃).

The ratio and flow rate of these gases are meticulously controlled to determine the stoichiometry (the elemental composition) and growth speed of the resulting film.

Why These Conditions are Used in Practice

The precise control over PECVD parameters makes it indispensable for a wide range of modern technologies where film properties are non-negotiable.

Dielectric Layers in Semiconductors

In microchip fabrication, PECVD is used to deposit insulating films like silicon dioxide (SiO₂) and silicon nitride (SiN). These serve as passivation layers to protect the device, or as hard masks and sacrificial layers during subsequent etching steps.

Optical and Barrier Coatings

PECVD is used to create anti-reflective coatings on lenses and solar cells. It is also used to deposit dense, inert barrier films on flexible food packaging to protect against oxygen and moisture, or on biomedical implants to ensure biocompatibility.

Mechanical and Tribological Films

For applications requiring high wear resistance, PECVD can deposit hard coatings like diamond-like carbon (DLC). The ion bombardment inherent in the plasma process can help create dense, durable films with low friction.

Understanding the Trade-offs and Limitations

While powerful, PECVD is a complex process with inherent challenges that require careful management.

The Challenge of Process Control

The key parameters—temperature, pressure, gas flow, and RF power—are all interconnected. A small drift in one can affect the others, leading to variations in film quality. Maintaining stable and reproducible conditions is a primary challenge.

The Inevitable Risk of Contamination

Because PECVD is a vacuum process, any residual gases or impurities inside the chamber can become incorporated into the growing film. This contamination can degrade the film's electrical, optical, or mechanical properties.

Film Quality vs. Deposition Temperature

The primary advantage of PECVD is its low temperature. However, this can be a trade-off. Films deposited at lower temperatures can sometimes have higher concentrations of hydrogen (from precursor gases) and lower density compared to films from high-temperature CVD processes.

Making the Right Choice for Your Goal

Your specific goal determines which parameters you must prioritize and control most carefully.

- If your primary focus is protecting a heat-sensitive substrate: The main benefit for you is the low-temperature capability (200-400°C), which prevents damage to polymers or completed integrated circuits.

- If your primary focus is a high-quality dielectric film: You must precisely control gas stoichiometry and RF power to achieve the desired refractive index, low electrical leakage, and minimal film stress.

- If your primary focus is a dense mechanical coating: You will likely operate at higher RF power levels to increase ion bombardment, which enhances film density and hardness.

- If your primary focus is process repeatability: Your priority is investing in a system with precise mass-flow controllers, stable pressure control, and reliable temperature management.

Ultimately, mastering PECVD is about understanding and controlling the interplay of its core conditions to engineer a film with the exact properties you need.

Summary Table:

| Parameter | Typical Range | Key Influence |

|---|---|---|

| Substrate Temperature | 200°C - 400°C | Enables low-temperature deposition for heat-sensitive substrates |

| Chamber Pressure | 1 - 2 Torr | Supports stable plasma generation and controls mean free path |

| RF Power | Varies | Affects plasma density, deposition rate, and film properties |

| Gas Composition | Precise control | Determines film stoichiometry and growth speed |

Ready to enhance your PECVD process with tailored solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, whether you're working on semiconductors, optical coatings, or mechanical films. Contact us today to discuss how we can optimize your deposition outcomes!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What makes PECVD a superior choice for industrial applications? Unlock Low-Temp, High-Quality Coatings

- Is PECVD directional? Understanding Its Non-Line-of-Sight Advantage for Complex Coatings

- What factors contribute to the efficiency of PECVD? Boost Thin-Film Deposition with Low-Temp Plasma

- What is the deposition pressure range for PECVD equipment? Optimize Film Quality and Deposition Speed

- How does the PECVD process work in single wafer chambers? Unlock Low-Temperature Thin Film Deposition

- What types of materials can be deposited using PECVD? Discover Versatile Thin Films for Your Applications

- What is PECVD used for? Enable Low-Temperature Thin Film Deposition for Advanced Manufacturing

- What are the advantages of plasma-enhanced deposition? Achieve Low-Temperature, High-Quality Thin Films