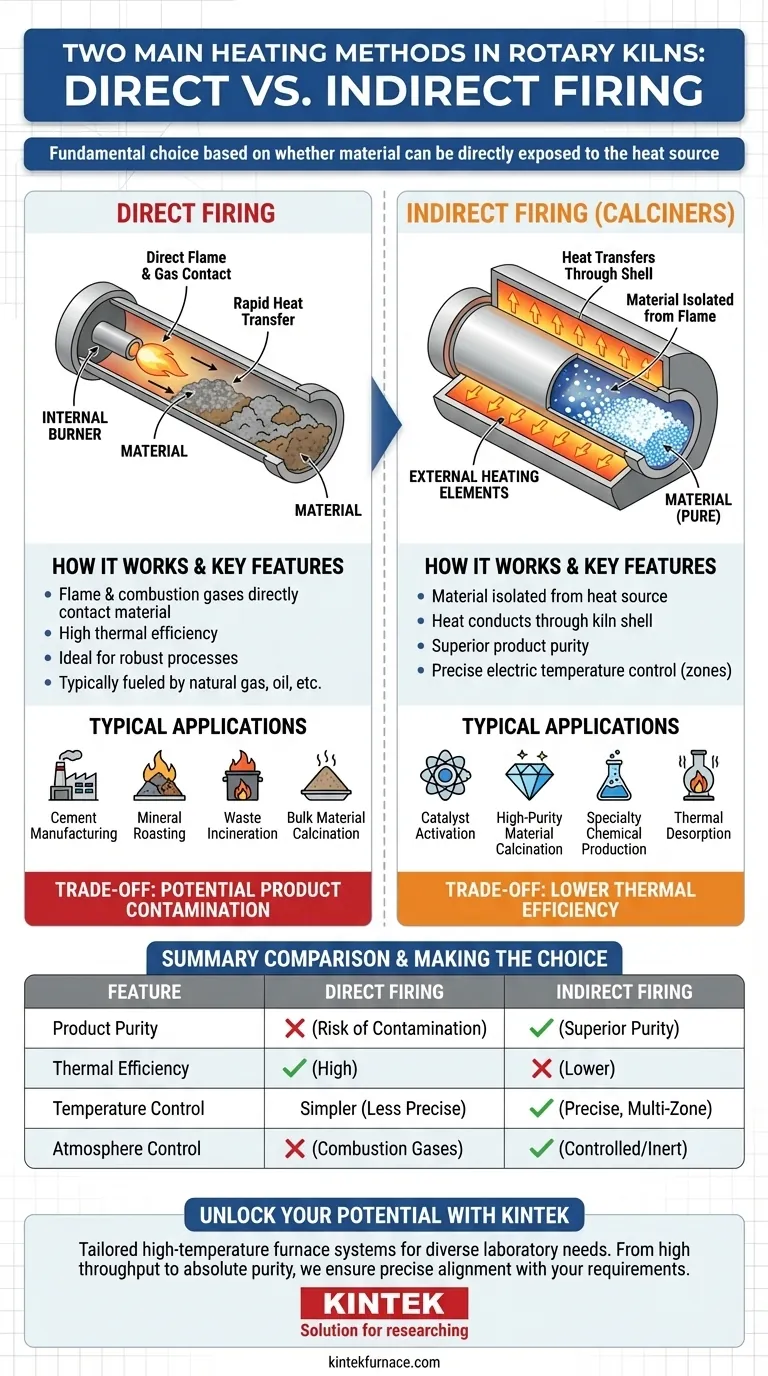

At a fundamental level, rotary kilns utilize two primary heating methods to achieve their thermal processing goals. The choice depends entirely on whether the material can be exposed to the heat source directly. The two methods are direct firing, where a burner's flame and combustion gases make direct contact with the material inside the kiln, and indirect firing, where the kiln is heated externally, and heat transfers through the shell to the material without any contact.

The decision between direct and indirect heating hinges on one critical factor: whether the material being processed can safely come into direct contact with the combustion flame and its byproducts. This single consideration dictates the entire design and application of the kiln system.

Understanding Direct-Fired Kilns

A direct-fired kiln is the most common configuration, designed for thermal efficiency and high throughput.

How Direct Heating Works

In a direct-fired system, a burner is positioned inside the kiln, typically at the discharge end. This burner injects a flame and hot combustion gases that flow through the kiln, directly interacting with the material as it tumbles.

This direct contact facilitates rapid and efficient heat transfer from the process gas to the solid material.

Common Fuels and Operation

These kilns are typically fueled by natural gas, heavy oil, or other combustible fuels. The atmosphere inside the kiln is a direct result of this combustion, containing byproducts like CO₂, water vapor, and potentially other trace elements from the fuel.

Typical Applications

Direct-fired kilns are ideal for robust processes where the final product is not sensitive to contamination from the combustion gas.

Common applications include cement manufacturing, mineral roasting, waste incineration, and the calcination of bulk materials like limestone, where direct contact is acceptable or even part of the chemical reaction.

Understanding Indirect-Fired Kilns (Calciners)

Indirect-fired kilns, often called calciners or retorts, are specialized units designed to isolate the material from the heat source.

How Indirect Heating Works

In this design, the rotating drum is enclosed within a furnace or surrounded by heating elements. Heat is applied to the outside of the kiln shell.

This heat then conducts through the metal or alloy shell to the material tumbling inside. The material never comes into contact with the flame or combustion gases, preserving a controlled and pure internal atmosphere.

The Advantage of Electric Heating

Many indirect kilns use electric resistance heaters as the external heat source. This method provides exceptionally precise and uniform temperature control.

These systems can be divided into multiple, independently controlled heating zones, allowing for a highly specific temperature profile along the length of the kiln. This is critical for sensitive chemical reactions.

Typical Applications

Indirect heating is essential when product purity is paramount. It is used for processes like catalyst activation, thermal desorption of sensitive compounds, specialty chemical production, and calcining high-purity materials where contamination would ruin the final product.

Understanding the Trade-offs

Choosing between these two methods involves a clear set of engineering and economic compromises.

Purity vs. Thermal Efficiency

Direct firing is generally more thermally efficient because heat is generated and transferred directly to the material with minimal loss. However, it always introduces the risk of product contamination.

Indirect firing guarantees product purity by isolating the material, but it is inherently less efficient. A significant amount of energy is lost transferring heat through the kiln shell and into the insulated furnace chamber.

Temperature Control vs. Simplicity

Indirect electric kilns offer the highest degree of temperature control, with the ability to manage multiple zones precisely.

Direct-fired systems are simpler in concept, but managing a precise temperature profile can be more challenging due to the dynamics of the internal flame and gas flow.

Atmosphere Control

In an indirect kiln, the internal atmosphere is completely independent of the heating method. This allows for processing in a fully inert (e.g., nitrogen) or reactive (e.g., hydrogen) atmosphere, which is impossible in a standard direct-fired kiln.

Making the Right Choice for Your Process

Your process requirements will point clearly to one method over the other.

- If your primary focus is high throughput for robust materials where contamination is not a concern: A direct-fired kiln is almost always the more economical and thermally efficient choice.

- If your primary focus is absolute product purity or processing in a controlled atmosphere: An indirect-fired kiln is the only viable solution, with electric models offering the most precise temperature control.

Ultimately, the heating method is not just a feature but the core design principle that defines the kiln's capabilities and limitations.

Summary Table:

| Heating Method | Key Mechanism | Ideal Applications | Key Benefits |

|---|---|---|---|

| Direct Firing | Burner flame and gases directly contact material | Cement manufacturing, mineral roasting, waste incineration | High thermal efficiency, high throughput, cost-effective |

| Indirect Firing | External heating through kiln shell, no direct contact | Catalyst activation, high-purity material calcining, sensitive chemical production | Superior product purity, precise temperature control, controlled atmosphere |

Unlock the full potential of your thermal processing with KINTEK's advanced rotary kiln solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental requirements, whether you need high throughput or absolute purity. Contact us today (#ContactForm) to discuss how our expertise can optimize your process efficiency and results!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- What are some common applications of rotary tube furnaces? Unlock Efficient Bulk Material Processing

- What are the key advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency for Your Materials

- How do rotary tube furnaces contribute to material science and chemical engineering? Unlock Precision in Material Processing

- How is heat transferred to the furnace tubes in a rotary tube furnace? Master Uniform Heating for Your Materials