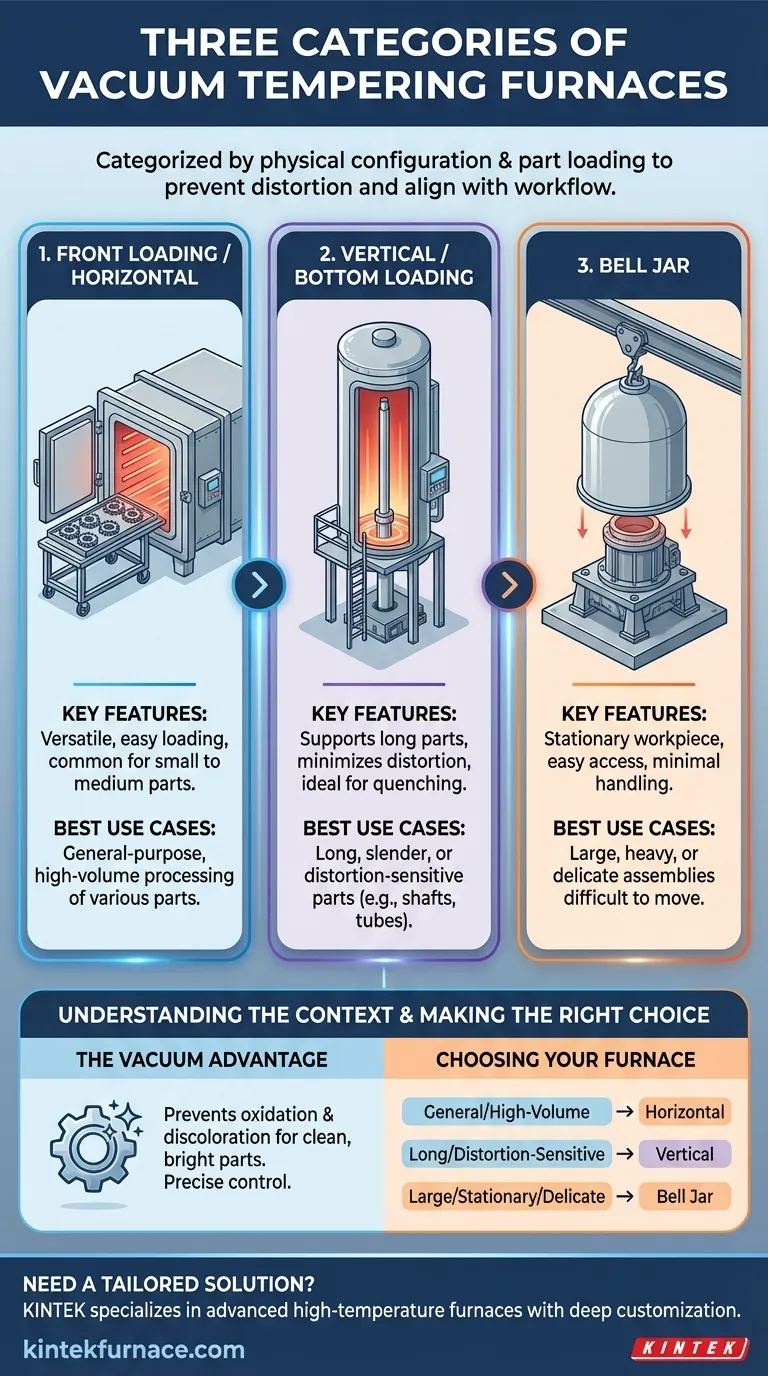

In vacuum heat treatment, tempering furnaces are primarily categorized by their physical configuration and how parts are loaded into the heating chamber. The three main categories are the Front Loading (Horizontal) Furnace, the Vertical (or Bottom Loading) Furnace, and the Bell Jar Furnace. Each design is optimized for specific part geometries, material handling logistics, and process requirements.

The choice between a horizontal, vertical, or bell jar furnace is not about the tempering process itself, but about the physical demands of the workpiece. The "best" furnace configuration is the one that prevents part distortion, simplifies loading, and aligns with your production workflow.

Deconstructing the Three Main Configurations

While all vacuum furnaces achieve a controlled, oxygen-free environment, their physical layout dictates their best use case. This configuration is the most fundamental way to classify them.

Front Loading / Horizontal Furnaces

This is the most common design, resembling a large, insulated box with a door on the front. Parts are loaded onto trays or fixtures, often manually or with a loading cart, and pushed into the horizontal hot zone.

Their popularity stems from their versatility and relative ease of use for a wide range of small to medium-sized parts. They are the workhorses of the heat treatment industry for general-purpose applications.

Vertical / Bottom Loading Furnaces

In a vertical furnace, the chamber is oriented upright. Parts are either lowered in from the top or, more commonly, loaded onto an elevator at the bottom that raises the workload into the stationary heating chamber.

This design is ideal for long, slender parts (like shafts or tubes) that would sag or distort if laid horizontally at high temperatures. It also excels in processes requiring a rapid drop into a quench tank (like oil quenching) located directly below the furnace.

Bell Jar Furnaces

This furnace operates on an inverted principle. The workpiece remains stationary on a fixed base, and the furnace chamber (the "bell jar") is lowered over it to create the vacuum seal and apply heat.

Bell jar furnaces are used for very large, heavy, or delicate assemblies that are difficult to move. This configuration minimizes material handling and allows for easy access to the workpiece for setup and instrumentation.

Beyond Configuration: Understanding Furnace Function

A furnace's name often describes its process more than its physical shape. A single horizontal furnace might be used for tempering one day and brazing the next, but it might be called a "tempering furnace" if that is its primary function.

Tempering vs. Other Heat Treatments

Tempering is a lower-temperature process (typically 150-650°C) performed after a part has been hardened to reduce brittleness and increase toughness.

Other common vacuum processes include:

- Hardening/Quenching: Heating to a high temperature and cooling rapidly to increase hardness.

- Annealing: Heating and slow cooling to soften a material and improve its ductility.

- Brazing: Joining two metals using a filler metal that melts at a lower temperature than the base metals.

- Sintering: Fusing metallic powders together under heat to form a solid part.

The Role of the Vacuum Environment

Using a vacuum is critical for modern heat treatment. It removes oxygen and other reactive gases, which prevents oxidation and discoloration, resulting in bright, clean parts that often require no post-process cleaning.

The vacuum also provides an extremely pure environment, allowing for precise control when introducing specific backfill gases like nitrogen or argon to achieve specific metallurgical outcomes.

Understanding the Trade-offs

No single furnace design is universally superior. The choice involves balancing cost, capability, and the physical nature of your parts.

Horizontal vs. Vertical Loading

Horizontal furnaces are generally simpler in design, less expensive, and require less overhead height. However, they risk part distortion for long or unstable components.

Vertical furnaces provide superior support against sagging and gravity-induced distortion. The trade-off is a higher initial cost, a larger vertical footprint, and more complex loading mechanisms.

Bell Jar Limitations

While ideal for oversized or stationary workpieces, bell jar furnaces are often less efficient for high-volume production of smaller parts. The cycle time can be longer compared to batch-processing horizontal or vertical furnaces.

Process-Specific Considerations

A furnace designed for high-temperature sintering (up to 2200°C) will be inefficient and costly to operate for low-temperature tempering. Conversely, a dedicated tempering furnace may not be able to reach the high temperatures required for brazing or hardening.

Making the Right Choice for Your Application

Selecting a furnace begins with analyzing your parts and production goals.

- If your primary focus is general-purpose, high-volume processing of various parts: A horizontal furnace is typically the most versatile and cost-effective choice.

- If your primary focus is processing long, tall, or distortion-sensitive parts: A vertical furnace configuration is the superior option to maintain dimensional stability.

- If your primary focus is working with large, stationary, or delicate assemblies: A bell jar furnace provides the best access and minimizes part movement during the process.

Understanding both the physical configuration and the intended thermal process is the key to selecting the right vacuum furnace technology.

Summary Table:

| Category | Key Features | Best Use Cases |

|---|---|---|

| Front Loading / Horizontal | Versatile, easy loading, common for small to medium parts | General-purpose, high-volume processing of various parts |

| Vertical / Bottom Loading | Supports long parts, minimizes distortion, ideal for quenching | Long, slender, or distortion-sensitive parts like shafts and tubes |

| Bell Jar | Stationary workpiece, easy access, minimal handling | Large, heavy, or delicate assemblies that are difficult to move |

Struggling to choose the right vacuum tempering furnace for your lab's unique needs? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your specific requirements. Our diverse product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by exceptional R&D and in-house manufacturing. With strong deep customization capabilities, we ensure precise alignment with your experimental goals, whether you're handling general-purpose parts, distortion-sensitive components, or large assemblies. Let us help you enhance efficiency and achieve superior results. Contact us today to discuss your project and discover how KINTEK can support your success!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance