At their core, a Chemical Vapor Deposition (CVD) tube furnace offers exceptionally precise temperature control through advanced, multi-stage intelligent program controllers. These systems are designed not just to reach a set temperature, but to execute complex thermal profiles with high accuracy (typically ±1°C), stability, and repeatability, which is fundamental to the CVD process of creating materials like thin films and nanomaterials.

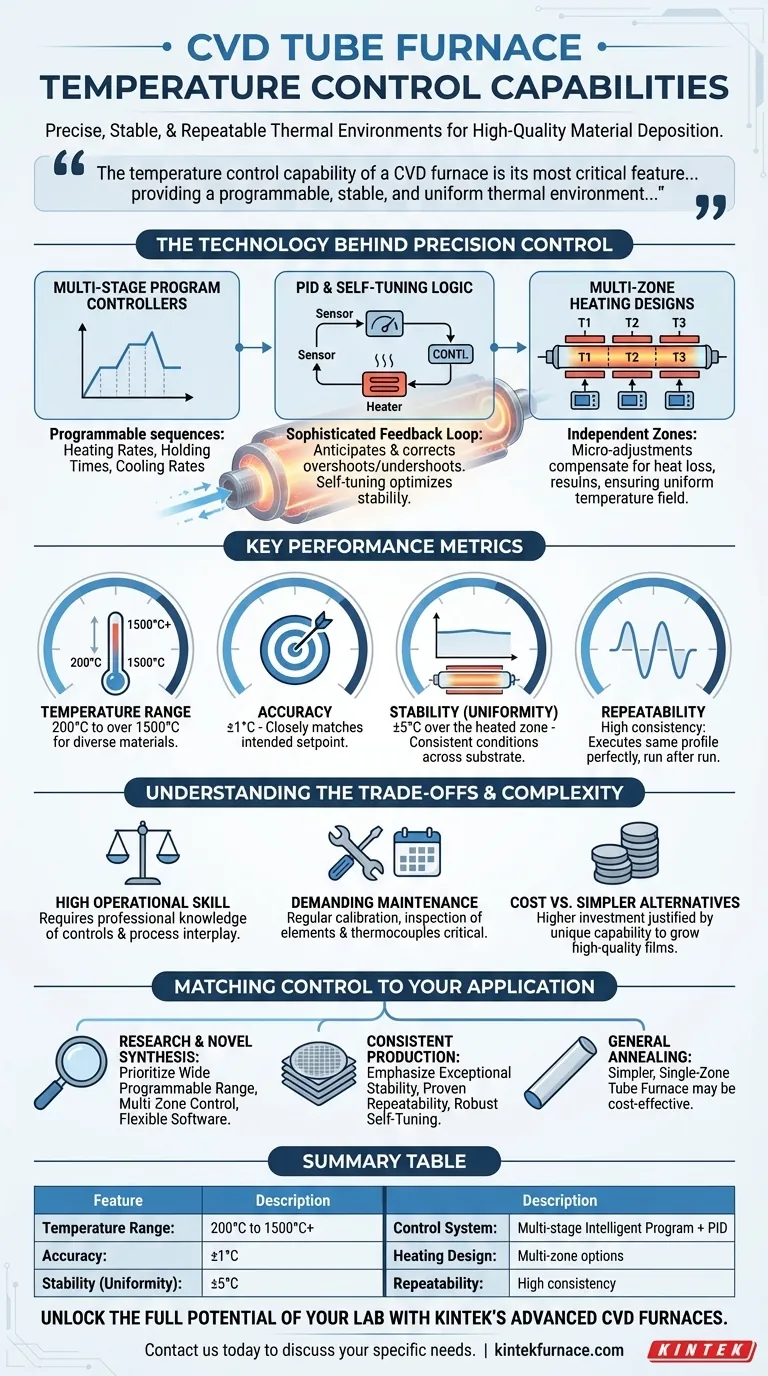

The temperature control capability of a CVD furnace is its most critical feature. It goes beyond simple heating to provide a programmable, stable, and uniform thermal environment, which is the non-negotiable foundation for driving the precise chemical reactions required for high-quality material deposition.

The Technology Behind Precision Control

A CVD furnace’s ability to manage temperature is not a single feature but a system of interacting components. Understanding these components reveals how such precision is achieved.

Multi-Stage Program Controllers

The brain of the system is a multi-stage intelligent program controller. Unlike a simple thermostat, this allows you to program a detailed sequence of temperature changes over time.

This means you can define specific heating rates (ramps), precise holding times (dwells) at target temperatures, and controlled cooling rates. This level of control is essential for managing the distinct phases of a CVD reaction.

PID and Self-Tuning Logic

To execute these programs accurately, furnaces rely on PID (Proportional-Integral-Derivative) control. This is a sophisticated feedback loop that continuously measures the furnace temperature and intelligently adjusts the power to the heating elements.

The PID algorithm anticipates and corrects for temperature overshoots and undershoots, ensuring the furnace follows the programmed profile with minimal deviation. Many modern controllers also feature self-tuning technology, which automatically optimizes the PID parameters for maximum stability.

Multi-Zone Heating Designs

For applications demanding the highest uniformity, some CVD furnaces feature a multi-zone design. The furnace tube is surrounded by several independent heating zones, each with its own controller and thermocouple.

This allows the system to make micro-adjustments along the length of the tube, compensating for heat loss at the ends and creating an exceptionally uniform temperature field across the entire substrate. This is critical for depositing films of consistent thickness and quality.

Key Performance Metrics Explained

When evaluating a CVD furnace, several key metrics define its temperature control performance.

Temperature Range

This defines the furnace's operational limits. CVD furnaces typically offer a wide range, often from 200°C to over 1500°C, accommodating the specific reaction temperatures required for a vast array of materials.

Temperature Accuracy

Accuracy refers to how closely the displayed temperature matches the actual temperature inside the furnace. A common specification is ±1°C, ensuring that the process is running at the intended thermal setpoint.

Temperature Stability (Uniformity)

Stability, often specified as temperature uniformity (e.g., ±5°C over the heated zone), describes how consistent the temperature is across the processing area and over time. High stability is paramount for ensuring every part of the substrate experiences the same conditions, leading to uniform material deposition.

Repeatability

Repeatability is the ability of the furnace to execute the exact same temperature profile perfectly, run after run. This is vital for both scientific research, where experiments must be reproducible, and in manufacturing, where product consistency is essential.

Understanding the Trade-offs and Complexity

The advanced capabilities of a CVD furnace come with necessary considerations. These are not simple laboratory ovens, and their precision introduces specific operational demands.

High Operational Skill Requirement

Effectively operating a CVD furnace requires professional knowledge. The user must understand not only the furnace controls but also the interplay between temperature, gas flow, and pressure to achieve the desired chemical reaction.

Demanding Maintenance Schedule

To maintain high accuracy and ensure a long service life, these systems require regular, technically demanding maintenance. Calibration of controllers, inspection of heating elements, and verification of thermocouples are critical tasks that cannot be neglected.

Cost vs. Simpler Alternatives

The complexity and precision of a CVD furnace translate to a higher initial cost and greater operational overhead compared to a standard tube furnace. The investment is justified by the unique capability to grow high-quality films and materials, a task simpler furnaces cannot perform.

Matching Control to Your Application

Choosing the right system means aligning its capabilities with your specific process goals.

- If your primary focus is research and novel material synthesis: Prioritize a wide programmable range, multi-zone heating control for creating thermal gradients, and flexible software.

- If your primary focus is consistent production of wafers or coatings: Emphasize exceptional temperature stability, proven repeatability, and robust self-tuning features to guarantee process consistency.

- If your primary focus is general thermal annealing or processing without deposition: A simpler, single-zone tube furnace may be a more cost-effective solution that is easier to operate and maintain.

Ultimately, mastering the temperature control of a CVD furnace is the first and most critical step toward mastering the material deposition process itself.

Summary Table:

| Feature | Description |

|---|---|

| Temperature Range | Typically 200°C to over 1500°C for diverse material synthesis |

| Accuracy | ±1°C for exact thermal setpoints |

| Stability (Uniformity) | ±5°C over the heated zone for consistent deposition |

| Control System | Multi-stage intelligent program controllers with PID and self-tuning |

| Heating Design | Multi-zone options for enhanced temperature uniformity |

| Repeatability | High consistency for reproducible experimental and production results |

Unlock the Full Potential of Your Lab with KINTEK's Advanced CVD Furnaces

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in research, material synthesis, or production, our furnaces deliver precise temperature control, stability, and repeatability for superior results.

Contact us today via our contact form to discuss how we can tailor a solution for your specific needs and enhance your lab's efficiency and innovation!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role do CVD tube furnace sintering systems play in 2D material synthesis? Enabling High-Quality Atomic Layer Growth

- What types of atmosphere control does a CVD Tube Furnace support? Master Vacuum and Gas Control for Precision

- Which industries and research fields benefit from CVD tube furnace sintering systems for 2D materials? Unlock Next-Gen Tech Innovations

- What is the working principle of a CVD tube furnace? Achieve Precise Thin Film Deposition for Your Lab

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films