At their core, multi-chamber continuous vacuum furnaces are automated, assembly-line systems designed for high-volume thermal processing. Their structure consists of a series of interconnected, isolated chambers—including loading, pre-heating, processing, cooling, and unloading zones. Operationally, they provide precise, computer-controlled environments with high temperatures and deep vacuums, enabling a continuous flow of product with exceptional consistency and purity.

These furnaces solve a fundamental industrial challenge: scaling high-purity thermal processes from slow, inconsistent batch operations to a continuous, reliable, and energy-efficient production line. They trade the flexibility of single-chamber systems for unparalleled throughput and repeatability in stable manufacturing environments.

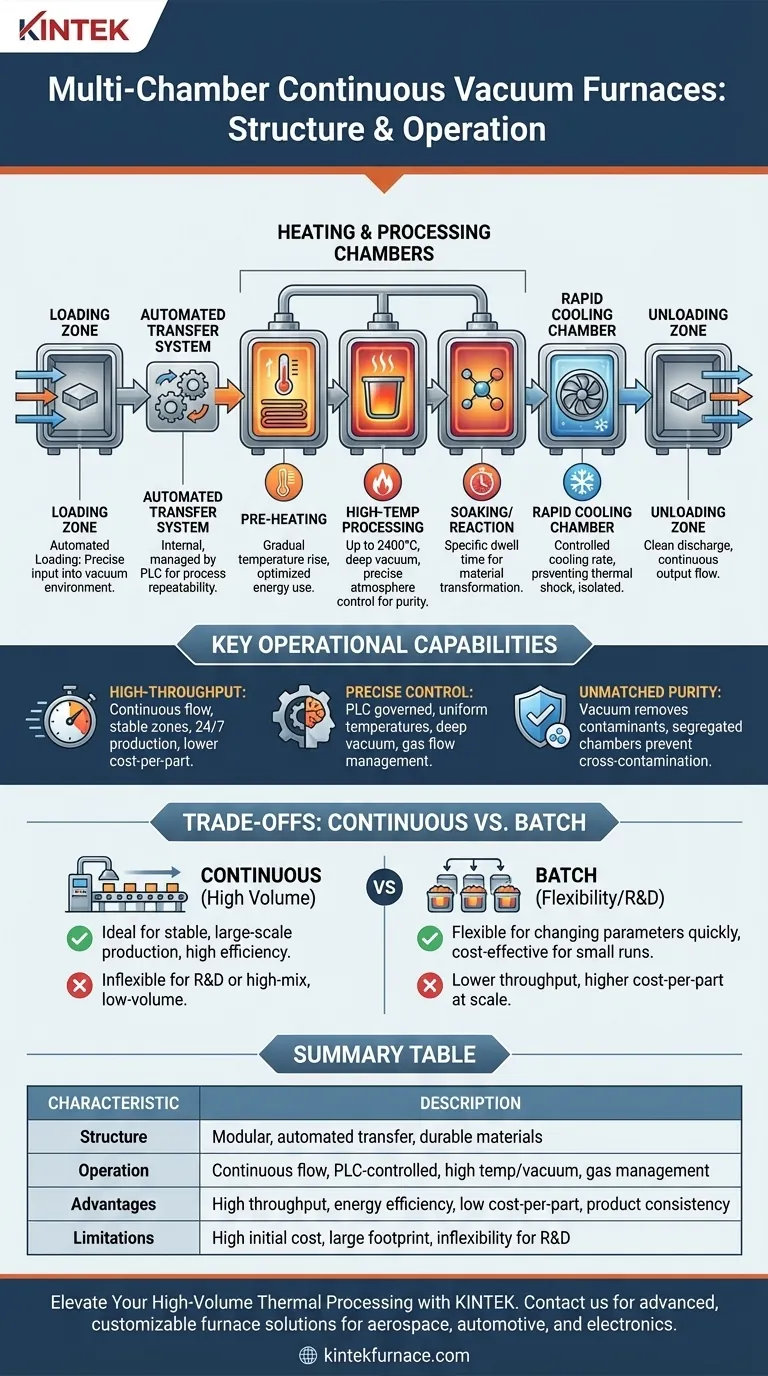

Deconstructing the Structure: An Automated Journey

A multi-chamber furnace is best understood as a linear sequence of specialized environments. Each part of the structure serves a distinct purpose in an integrated, automated workflow.

The Modular, Multi-Chamber Design

The defining structural feature is the series of interconnected yet individually sealed chambers. A typical sequence includes a loading chamber, one or more heating and processing chambers, and a rapid cooling chamber before the final unloading station.

This modularity allows for the isolation of process steps. Heating, high-temperature processing, and cooling occur in separate, optimized zones, preventing cross-contamination and improving thermal efficiency.

The Automated Transfer System

Parts are moved from one chamber to the next via an internal, fully automated transfer mechanism. This system is the electromechanical heart of the furnace, managed by a central controller.

This automation eliminates manual handling, which is a primary source of process variability and contamination. It guarantees that every part experiences the exact same thermal cycle, ensuring unmatched process repeatability.

Robust Materials for Extreme Conditions

The internal components, particularly the "hot zone" where heating occurs, are built from materials selected for extreme durability. These often include graphite composites or refractory metals.

These materials provide excellent heat and corrosion resistance, low thermal conductivity, and chemical stability. This ensures a long service life and prevents the furnace itself from becoming a source of product contamination.

Key Operational Capabilities and Their Impact

The structure enables a unique set of operational capabilities that distinguish these furnaces from simpler batch systems.

High-Throughput Continuous Processing

Unlike a single-chamber furnace that must be heated and cooled for every batch, a continuous furnace keeps its various zones at a constant operational state. The product moves through the stable temperature zones.

This eliminates thermal cycling of the entire furnace, dramatically increasing throughput and making the system ideal for large-scale, 24/7 production.

Precise Environmental Control

Modern systems are governed by a Programmable Logic Controller (PLC). This central brain provides comprehensive automation and precise control over all critical parameters.

This includes maintaining uniform temperatures up to 2400°C or higher, achieving deep vacuum levels to remove atmospheric contaminants, and managing digital gas flow for specific process atmospheres.

Unmatched Product Purity

The combination of a high vacuum environment and segregated process chambers is key to achieving high purity. The vacuum removes oxygen and other reactive gases, while the system can actively pump away by-products released during heating.

This operational capability is critical for applications like brazing, sintering, and annealing of sensitive materials where oxidation or contamination would lead to component failure.

Understanding the Trade-offs: Continuous vs. Batch

While powerful, a multi-chamber continuous furnace is not a universal solution. The primary trade-off is between throughput and flexibility.

The Advantage: High-Volume Production

For a manufacturer producing thousands of identical parts with a stable, locked-in process, the continuous furnace is superior. The energy efficiency, speed, and repeatability deliver a lower cost-per-part at scale.

The Limitation: Process Inflexibility

These furnaces are not well-suited for research and development or high-mix, low-volume production. Changing a core parameter like processing temperature is a significant undertaking, as it requires the entire line to be stabilized at the new setpoint.

The Upfront Investment

The complexity of the multi-chamber design and its sophisticated automation systems results in a significantly higher initial capital cost and a larger physical footprint compared to single-chamber batch furnaces.

Making the Right Choice for Your Application

Selecting the correct furnace technology depends entirely on your production goals and operational context.

- If your primary focus is high-volume, stable production of a single part or family of parts: A multi-chamber continuous furnace offers the best path to efficiency, consistency, and low operational cost per unit.

- If your primary focus is research, process development, or producing small, varied batches: A single-chamber batch furnace provides the necessary flexibility to change parameters quickly and cost-effectively.

Ultimately, choosing the right furnace is about matching the tool's inherent design philosophy to your specific manufacturing strategy.

Summary Table:

| Characteristic | Description |

|---|---|

| Structure | Modular chambers (loading, heating, cooling, unloading) with automated transfer and durable materials for isolation and efficiency. |

| Operation | Continuous flow, PLC-controlled environments with high temperatures (up to 2400°C), deep vacuum, and gas management for repeatability and purity. |

| Advantages | High throughput, energy efficiency, low cost-per-part, and unmatched product consistency in stable production settings. |

| Limitations | High initial cost, large footprint, and inflexibility for R&D or low-volume batches compared to batch furnaces. |

Ready to elevate your high-volume thermal processing? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for industries like aerospace, automotive, and electronics. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Contact us today to discuss how our multi-chamber continuous vacuum furnaces can boost your efficiency and product purity!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How are multi zone tube furnaces used in ceramics, metallurgy and glass research? Unlock Precise Thermal Control for Advanced Materials

- What advantages do multi zone tube furnaces offer for chemical reaction studies? Achieve Precise Thermal Control

- How do multi zone tube furnaces improve laboratory efficiency? Boost Throughput with Parallel Processing

- How does a multi-zone tube furnace achieve precise temperature gradient control? Master MoS2 Isotope Monolayer Synthesis

- What preparations are needed before starting a multi zone tube furnace? Ensure Safety and Accuracy in Your Lab