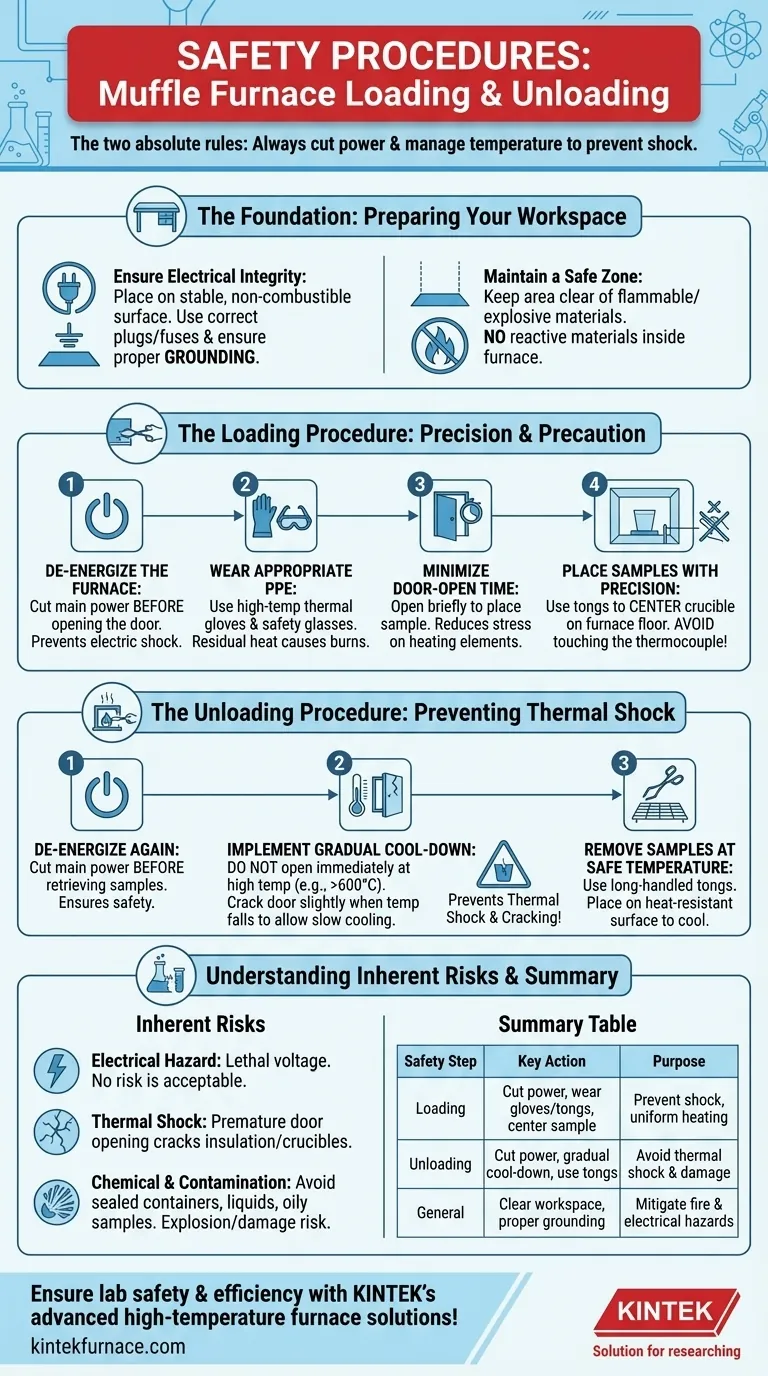

The most critical safety procedures for a muffle furnace involve two absolute rules: always cut the power supply before loading or unloading samples to prevent electric shock, and manage temperature changes carefully to prevent thermal shock to the equipment. You must wear high-temperature protective gloves and use tongs, placing samples in the center of the chamber while keeping the door open for the shortest possible time.

A muffle furnace is not just a simple oven; it's a high-energy system where electrical and thermal hazards are significant. True safety is not about a single checklist but about a disciplined process that respects these forces before, during, and after every single use.

The Foundation: Preparing Your Workspace

Before you even consider turning the furnace on, you must ensure the environment is fundamentally safe. The initial setup dictates the safety of all future operations.

Ensure Electrical Integrity

The furnace must be placed on a stable, non-combustible surface, such as a dedicated cement platform. It requires appropriate plugs, sockets, and fuses rated for its power draw, and it is essential that the unit is properly grounded to prevent electrical faults from energizing the chassis.

Maintain a Safe Zone

The area around the muffle furnace must be kept completely clear of flammable, explosive, or corrosive materials. These furnaces radiate intense heat, and nearby combustible items pose a serious fire risk. Never place explosive or dangerously reactive materials inside the furnace.

The Loading Procedure: Precision and Precaution

Loading the furnace is a moment of direct interaction with a potentially hazardous system. Each step is designed to mitigate a specific risk.

Step 1: De-Energize the Furnace

This is non-negotiable. Before opening the door to load a sample, you must completely cut off the main power supply. This eliminates the risk of fatal electric shock from contact with exposed heating elements.

Step 2: Wear Appropriate PPE

Always wear high-temperature-rated thermal gloves and safety glasses. Even if the furnace is at a lower temperature, residual heat in the insulation and door can cause severe burns instantly.

Step 3: Minimize Door-Open Time

Open the furnace door only as long as is necessary to place your sample. Prolonged opening causes a rapid temperature drop, which stresses the heating elements and refractory brick lining, significantly shortening the furnace's operational lifespan.

Step 4: Place Samples with Precision

Using long-handled tongs, place your crucible or sample directly in the center of the furnace floor. This ensures the most uniform heating. Crucially, do not let your sample or tongs touch the thermocouple, which is the small rod-like temperature sensor extending into the chamber. It is fragile at high temperatures and can easily break.

The Unloading Procedure: Preventing Thermal Shock

Unloading is arguably the most critical phase for equipment longevity. Rushing this process is the most common cause of furnace damage.

Step 1: De-Energize Again

Just as with loading, the first step before retrieving your sample is to cut the main power supply. This ensures your safety as you prepare to open the door and reach inside with tools.

Step 2: Implement a Gradual Cool-Down

Do not open the door immediately after the heating cycle is complete, especially if the internal temperature is high (e.g., above 600°C). Opening the door suddenly introduces a rush of cool air, creating a massive thermal shock that can crack the refractory insulation or even the sample itself.

Instead, allow the furnace to cool naturally. Once the temperature has fallen significantly, you can crack the door open a small amount to allow for slow, controlled cooling before opening it fully.

Step 3: Remove Samples at a Safe Temperature

Once the furnace has cooled to a manageable temperature, use long-handled crucible tongs to carefully remove your items. Place them on a designated heat-resistant surface to cool to room temperature.

Understanding the Inherent Risks

Adhering to procedure is easier when you understand the consequences of failure. The rules exist to counteract specific, predictable dangers.

Electrical Hazard vs. Convenience

It may seem inconvenient to power the unit down for a quick sample swap, but the heating elements carry lethal voltage. There is no acceptable level of risk when it comes to electrical safety.

Thermal Shock vs. Speed

The desire to get results quickly can lead to premature door opening. This single action is the primary cause of cracked insulation and damaged crucibles. A few extra minutes of patient cooling can save thousands of dollars in repairs and prevent catastrophic equipment failure.

Chemical and Contamination Risks

Never heat sealed containers, liquids, or excessively oily samples directly in the furnace. The rapid expansion of gases can create an explosion, and liquids can damage the furnace floor and heating elements. The sealed muffle chamber is designed to protect the sample from combustion gases, not to contain volatile reactions.

Making the Right Choice for Your Goal

Your priorities will dictate which safety principles you emphasize most, but all are interconnected.

- If your primary focus is operator safety: The non-negotiable rule is to always de-energize the furnace before your hands or any tools cross the threshold of the door.

- If your primary focus is equipment longevity: The key is mastering thermal management by minimizing door-open time during loading and executing a patient, gradual cool-down during unloading.

- If your primary focus is process reliability: Precise, centered sample placement away from the thermocouple is essential for ensuring uniform heating and obtaining accurate temperature data.

Ultimately, disciplined and safe operation is the foundation of reliable and repeatable results.

Summary Table:

| Safety Step | Key Action | Purpose |

|---|---|---|

| Loading | Cut power, wear gloves/tongs, center sample | Prevent electric shock and ensure uniform heating |

| Unloading | Cut power, gradual cool-down, use tongs | Avoid thermal shock and equipment damage |

| General | Clear workspace, proper grounding | Mitigate fire and electrical hazards |

Ensure your lab's safety and efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs. Contact us today to discuss how we can enhance your processes and protect your investments!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing