At their core, IGBT induction melting furnaces offer a superior combination of efficiency, speed, and precision compared to older technologies. Their primary advantages are significantly lower energy consumption, faster melting cycles that increase productivity, and precise digital control over the melting process, which results in higher-quality, purer final metals.

The fundamental advantage of IGBT technology is not just one single feature, but how its precise, high-frequency power control unlocks simultaneous improvements in cost, speed, and quality, fundamentally changing the economics of metal melting.

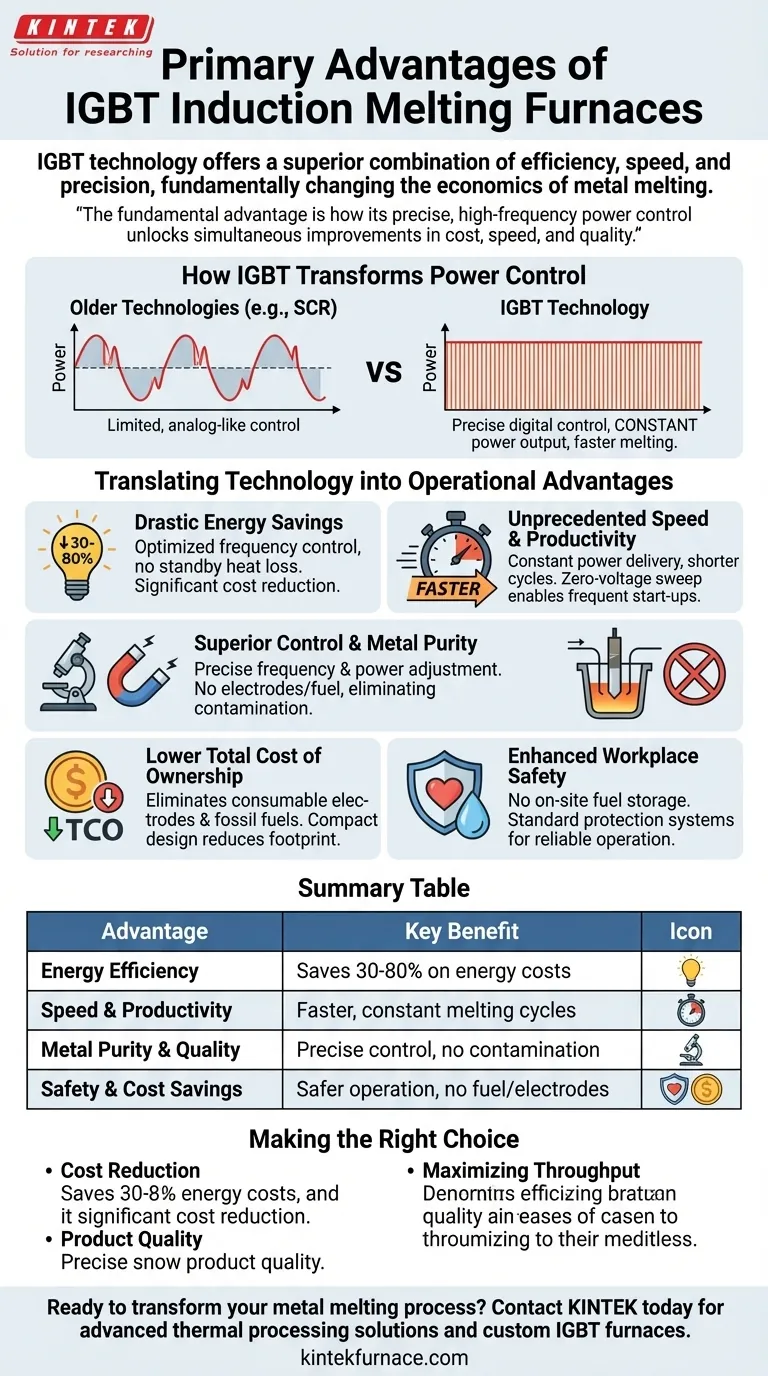

The Core Principle: How IGBT Transforms Power Control

Modern induction furnaces rely on Insulated Gate Bipolar Transistors (IGBTs) as their core power switching component. Understanding this technology is key to grasping its benefits over older systems, such as those using SCR (Silicon-Controlled Rectifier) technology.

From Coarse to Fine-Tuned Power

Older furnace technologies offered limited, almost analog-like control over power delivery.

IGBTs, however, are high-speed semiconductor switches. They allow for the precise digital control of high-frequency electrical currents, giving operators an unprecedented level of command over the energy entering the melt.

Achieving Constant Power Output

This precise control allows the furnace to maintain a constant power output throughout the melting cycle.

Unlike systems where power might taper off, an IGBT furnace works at its optimal level consistently. This directly translates to more predictable and significantly faster melting speeds.

Translating Technology into Operational Advantages

The technical superiority of IGBTs creates tangible benefits that impact every aspect of a melting operation, from the utility bill to the quality of the final cast.

Drastic Reductions in Energy Consumption

IGBT-based systems are exceptionally efficient at converting electrical power into heat within the metal. The references indicate energy savings of 30% to 80% compared to traditional fuel-fired methods.

This efficiency comes from optimized frequency control and the elimination of standby heat loss. The furnace only consumes significant power when it is actively melting.

Unprecedented Speed and Productivity

Faster heating rates directly lead to increased productivity. With constant power delivery, melting times are shorter and more repeatable.

Furthermore, features like zero-voltage sweep software enable the system to handle frequent start-ups and shutdowns without issue, making it ideal for dynamic production schedules and varied casting processes.

Superior Control and Metal Purity

By allowing for the precise adjustment of the electromagnetic field's frequency and power, operators can finely control temperature and the stirring action within the molten bath.

This control leads to more homogenous alloys and helps separate impurities from the metal. Because induction heating requires no electrodes or fuel, it also eliminates a major source of contamination, resulting in superior metal purity.

Understanding the Financial and Safety Implications

While the initial investment in modern technology is a key consideration, the long-term operational benefits often present a compelling financial case.

Lowering the Total Cost of Ownership

The significant energy savings are the most direct financial benefit. However, costs are also reduced by the elimination of consumable electrodes and fossil fuels.

The compact, space-saving design of many modern IGBT furnaces can also reduce infrastructure and operational footprint costs, making them viable even for smaller facilities.

Enhancing Workplace Safety

Induction melting is an inherently safer process. It removes the need for on-site fuel storage and eliminates the risks associated with handling combustible fuels.

Comprehensive protection systems are standard, monitoring for over-current, over-voltage, and water shortages to ensure reliable and safe operation.

Making the Right Choice for Your Operation

The decision to adopt an IGBT induction furnace should be aligned with your specific operational priorities.

- If your primary focus is cost reduction: The dramatic energy savings and elimination of fuel and electrode costs provide a clear and rapid return on investment.

- If your primary focus is product quality: The precise temperature control and lack of contamination sources ensure higher metal purity and alloy consistency.

- If your primary focus is maximizing throughput: The faster melt times and ability to perform frequent starts deliver a significant boost to overall productivity.

Ultimately, adopting IGBT induction technology is a strategic move toward a more efficient, controllable, and profitable melting process.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Energy Efficiency | Saves 30-80% on energy costs vs. traditional methods |

| Speed & Productivity | Faster, constant melting cycles for higher throughput |

| Metal Purity & Quality | Precise temperature control eliminates contamination |

| Safety & Cost Savings | Safer operation, no fuel or consumable electrodes needed |

Ready to transform your metal melting process with superior efficiency and control?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and foundries with advanced thermal processing solutions. Our product line, including high-performance IGBT Induction Melting Furnaces, Muffle Furnaces, Tube Furnaces, and Vacuum & Atmosphere Furnaces, is complemented by our strong deep customization capability to precisely meet your unique production requirements.

Contact KINTEK today to discuss how our IGBT furnace technology can reduce your costs and enhance your product quality.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys