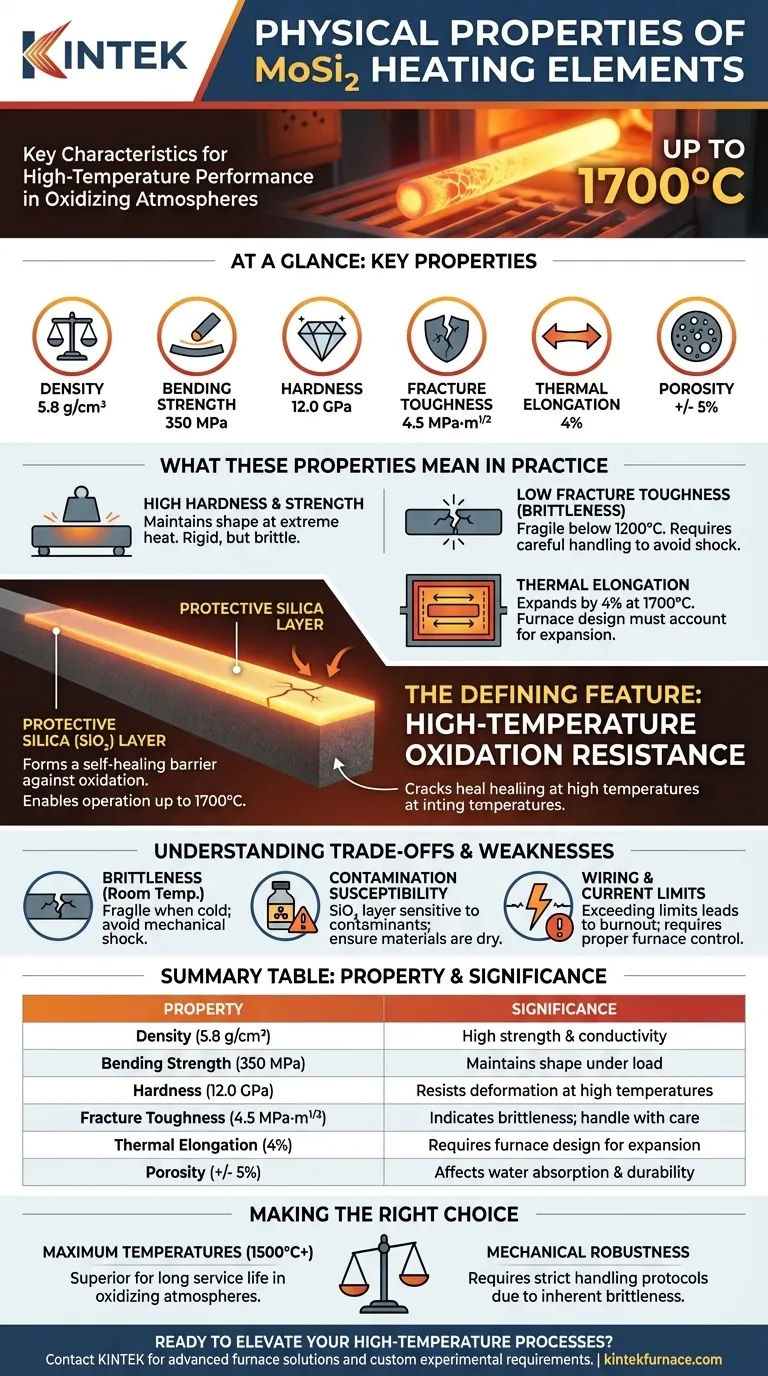

At a glance, the key physical properties of Molybdenum Disilicide (MoSi₂) heating elements include a density of 5.8 g/cm³, high bending strength of 350 MPa, and exceptional hardness of 12.0 GPa. These figures are complemented by a low fracture toughness of 4.5 MPa·m¹/², thermal elongation of 4%, and a porosity of around +/- 5%.

The defining characteristic of MoSi₂ is a combination of properties that make it exceptional for high-temperature work in oxidizing atmospheres, but also inherently brittle at room temperature. Understanding this trade-off is critical for its successful implementation.

What the Physical Properties Mean in Practice

The datasheet values for MoSi₂ elements translate directly into real-world performance advantages and handling requirements. These are not just numbers; they define how the element behaves in a furnace.

High Hardness and Strength

With a hardness of 12.0 GPa and a compression strength of 650 MPa, MoSi₂ is an extremely hard and rigid material.

This structural integrity allows it to maintain its shape under its own weight at extreme temperatures where metals would fail. However, this hardness is coupled with brittleness.

Low Fracture Toughness

A fracture toughness of 4.5 MPa·m¹/² is relatively low. This is the technical measurement for brittleness.

This means that while the element is strong, it cannot absorb much impact or shock before cracking. This property makes careful handling during installation and maintenance absolutely essential.

Thermal Elongation

The thermal elongation of 4% means the element will physically expand as it heats to its operating temperature of 1700°C or higher.

Furnace design must account for this expansion to prevent the element from pressing against the furnace walls or other components, which would create mechanical stress and lead to failure.

Density and Porosity

The density of 5.8 g/cm³ and porosity of +/- 5% are outcomes of the powder metallurgy process used to create the elements.

While high density is desired for strength and conductivity, some minor porosity is inherent. This can contribute to its only 0.6% water absorption, a factor that becomes relevant if elements are stored improperly or if furnace conditions are not managed correctly.

The Defining Feature: High-Temperature Oxidation Resistance

The single most important characteristic of MoSi₂ is its ability to protect itself from oxidation at extreme temperatures. This is the core reason it is chosen for demanding applications.

The Protective Silica (SiO₂) Layer

When heated in an oxygen-containing atmosphere, the surface of the MoSi₂ element forms a thin, non-porous layer of glassy silica (SiO₂).

This layer acts as a barrier, preventing further oxidation of the underlying material. If the layer is damaged by a crack, it will "self-heal" by re-forming at high temperatures, giving the element its renowned antioxidant and auto-repair functions.

Enabling Extreme Temperatures

This protective layer is what allows MoSi₂ elements to operate reliably in furnace temperatures up to 1700°C and even higher, with the element surface itself reaching up to 1900°C.

This makes it the material of choice for high-temperature sintering of ceramics, glass production, and advanced materials research where consistent, extreme heat is required.

Understanding the Trade-offs and Weaknesses

No material is perfect. The exceptional high-temperature performance of MoSi₂ comes with specific vulnerabilities that must be managed.

Brittleness at Room Temperature

As highlighted by its low fracture toughness, MoSi₂ is very fragile below approximately 1200°C. It behaves like a ceramic.

This is its primary handling weakness. Dropping an element or subjecting it to mechanical shock during installation is the most common cause of premature failure.

Susceptibility to Contamination

The protective silica layer, while robust, can be compromised by certain contaminants. This is a critical operational risk.

Technicians must ensure materials placed in the furnace, such as colored zirconia, are properly dried. Any paints or foreign substances can react with the silica layer at high temperatures, degrading its protective quality and leading to rapid element failure.

Wiring and Current Limits

MoSi₂ elements are typically wired in series and have a maximum current limit. Exceeding this amperage will cause the element to overheat and burn out.

Proper furnace control and system design are essential to ensure the elements operate within their specified electrical parameters.

Making the Right Choice for Your Application

Your decision to use MoSi₂ should be based on a clear understanding of its strengths and the operational discipline required to mitigate its weaknesses.

- If your primary focus is reaching the highest possible temperatures (1500°C+): MoSi₂ is the superior choice due to its self-healing protective layer, offering a long service life in oxidizing atmospheres.

- If your primary focus is mechanical robustness and frequent handling: The inherent brittleness of MoSi₂ requires strict protocols for installation and maintenance to prevent damage.

- If you are operating in a clean, oxygen-rich environment: MoSi₂ will deliver its maximum performance and lifespan, making it ideal for applications like ceramic and dental furnace sintering.

- If your process involves potential contaminants or requires rapid cycling from cold: You must implement rigorous furnace maintenance and drying procedures to protect the elements from chemical attack and thermal shock.

Ultimately, harnessing the power of MoSi₂ heating elements is a balance between leveraging their extreme temperature capabilities and respecting their material limitations.

Summary Table:

| Property | Value | Significance |

|---|---|---|

| Density | 5.8 g/cm³ | High strength and conductivity |

| Bending Strength | 350 MPa | Maintains shape under load |

| Hardness | 12.0 GPa | Resists deformation at high temperatures |

| Fracture Toughness | 4.5 MPa·m¹/² | Indicates brittleness; handle with care |

| Thermal Elongation | 4% | Requires furnace design for expansion |

| Porosity | +/- 5% | Affects water absorption and durability |

Ready to elevate your high-temperature processes with reliable MoSi2 heating elements? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization capabilities to meet your unique experimental requirements. Contact us today to discuss how our expertise can optimize your lab's performance and durability!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions