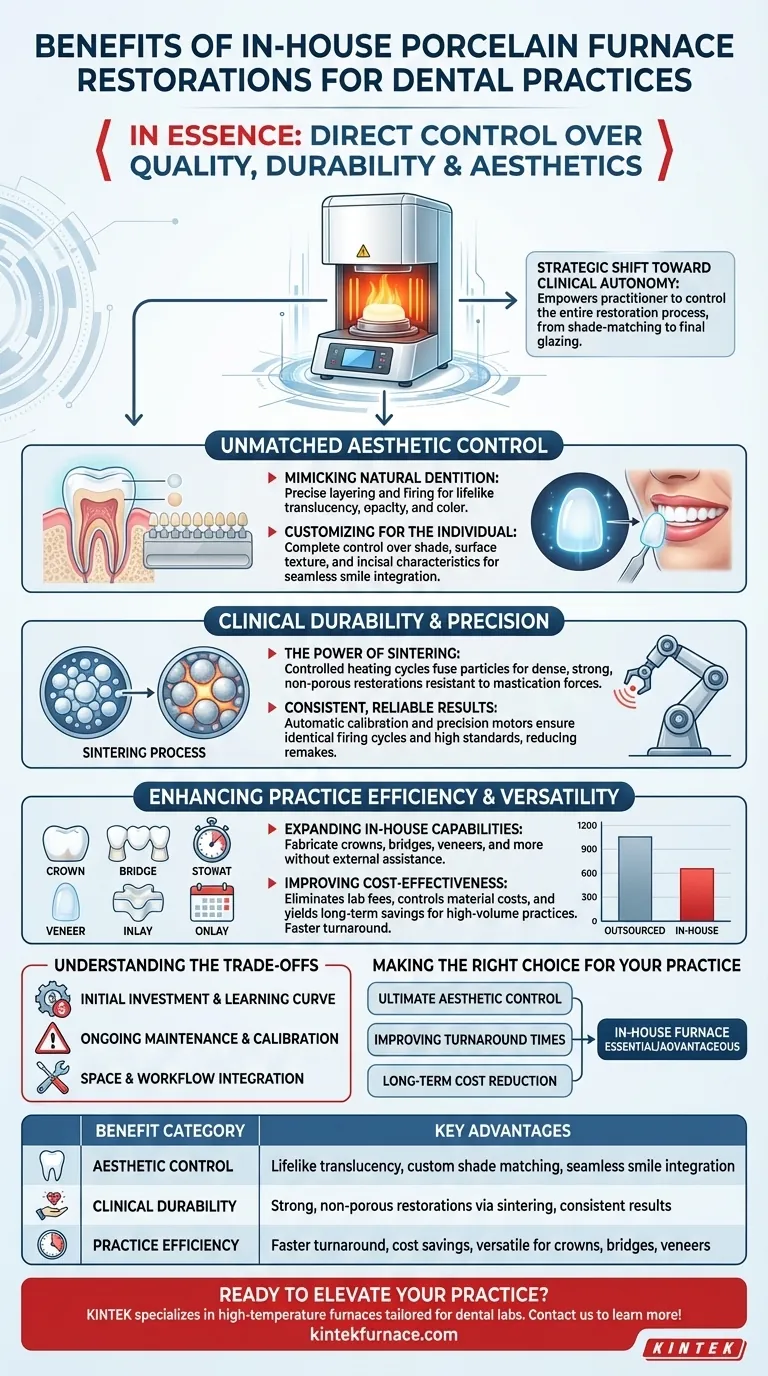

In essence, a porcelain furnace gives a dental practice direct control over the quality, durability, and aesthetics of ceramic restorations. This investment enhances the functional performance of crowns, bridges, and veneers while significantly improving patient satisfaction and practice efficiency.

The core benefit of an in-house porcelain furnace is a strategic shift toward clinical autonomy. It empowers the practitioner to control the entire restoration process, from shade-matching to final glazing, ensuring a higher standard of care without dependence on external lab schedules or interpretations.

Achieving Unmatched Aesthetic Control

The primary driver for many practices investing in a porcelain furnace is the ability to create lifelike restorations that are indistinguishable from natural teeth.

Mimicking Natural Dentition

A furnace allows for the precise layering and firing of ceramic powders. This process builds up translucency, opacity, and color from within the restoration, perfectly mimicking the complex structure of a natural tooth.

Customizing for the Individual

You gain complete control over the final shade, surface texture, and incisal characteristics. This enables you to create a truly bespoke restoration that blends seamlessly with the patient's unique smile, a level of detail often lost when delegating to an external lab.

Engineering for Clinical Durability and Precision

Modern porcelain furnaces are not just for aesthetics; they are precision instruments designed to create strong, long-lasting restorations.

The Power of Sintering

The furnace executes highly controlled heating cycles, a process known as sintering. This fuses the ceramic particles together, creating a dense, non-porous material that is exceptionally strong and resistant to the forces of mastication.

Ensuring Consistent, Reliable Results

Advanced furnaces feature automatic temperature calibration and precision stepper motors. These features guarantee that every firing cycle is identical, eliminating variables and ensuring that each restoration meets the same high standard of strength and fit. This consistency dramatically reduces the need for adjustments or remakes.

Enhancing Practice Efficiency and Versatility

Integrating a furnace into your workflow can have a profound impact on the operational and financial health of your practice.

Expanding In-House Capabilities

A single furnace can be used to fabricate a wide range of restorations. This includes crowns, bridges, veneers, inlays, and onlays, giving your practice the versatility to handle most indirect restorative cases without external assistance.

Improving Cost-Effectiveness

While there is an initial investment, producing restorations in-house can be more cost-effective than outsourcing, especially for practices with a moderate to high volume of ceramic work. You gain control over material costs and eliminate lab fees.

Understanding the Trade-offs

While the benefits are significant, a porcelain furnace represents a strategic commitment that requires careful consideration.

The Initial Investment and Learning Curve

The primary barrier is the upfront capital cost of the furnace and associated equipment. Furthermore, staff must be properly trained on firing protocols, material handling, and maintenance to achieve consistent, high-quality results.

Ongoing Maintenance and Calibration

Like any piece of precision equipment, a porcelain furnace requires regular maintenance and calibration. Neglecting this can lead to inconsistent firing, poor aesthetic outcomes, and weakened restorations, undermining the very benefits you seek.

Space and Workflow Integration

You must allocate dedicated space within your practice or in-house lab. The workflow for designing, milling (if applicable), staining, glazing, and firing must be carefully integrated into your existing operations to maximize efficiency.

Making the Right Choice for Your Practice

Deciding whether to invest in a porcelain furnace depends entirely on your practice's specific goals.

- If your primary focus is ultimate aesthetic control: An in-house furnace is essential for achieving perfect shade matching and characterization, especially for demanding anterior cases.

- If your primary focus is improving turnaround times: Bringing the firing process in-house can dramatically reduce patient wait times and allow for same-day or next-day delivery of final restorations.

- If your primary focus is long-term cost reduction: For practices with a steady volume of ceramic cases, the initial investment can yield significant savings over time by eliminating external lab fees.

Ultimately, a porcelain furnace is a tool that empowers your practice to deliver a superior, highly customized restorative product with greater clinical confidence and control.

Summary Table:

| Benefit Category | Key Advantages |

|---|---|

| Aesthetic Control | Lifelike translucency, custom shade matching, seamless smile integration |

| Clinical Durability | Strong, non-porous restorations via sintering, consistent results |

| Practice Efficiency | Faster turnaround, cost savings, versatile for crowns, bridges, veneers |

Ready to elevate your dental practice with advanced porcelain furnace solutions? KINTEK specializes in high-temperature furnaces tailored for dental labs, offering products like Muffle, Tube, and Vacuum Furnaces with deep customization to meet your unique needs. Enhance your restorative capabilities and patient outcomes—contact us today to learn more!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations