From a technical standpoint, the primary advantages of a box type annealing atmosphere furnace are its simplified maintenance through modular design and its operational efficiency driven by precise process control. These features directly contribute to reduced downtime, consistent product quality, and lower long-term operating costs.

The core benefit is not a single feature, but the integration of user-friendly operation, efficient performance, and straightforward maintenance. This combination creates a reliable and cost-effective system for demanding heat treatment applications.

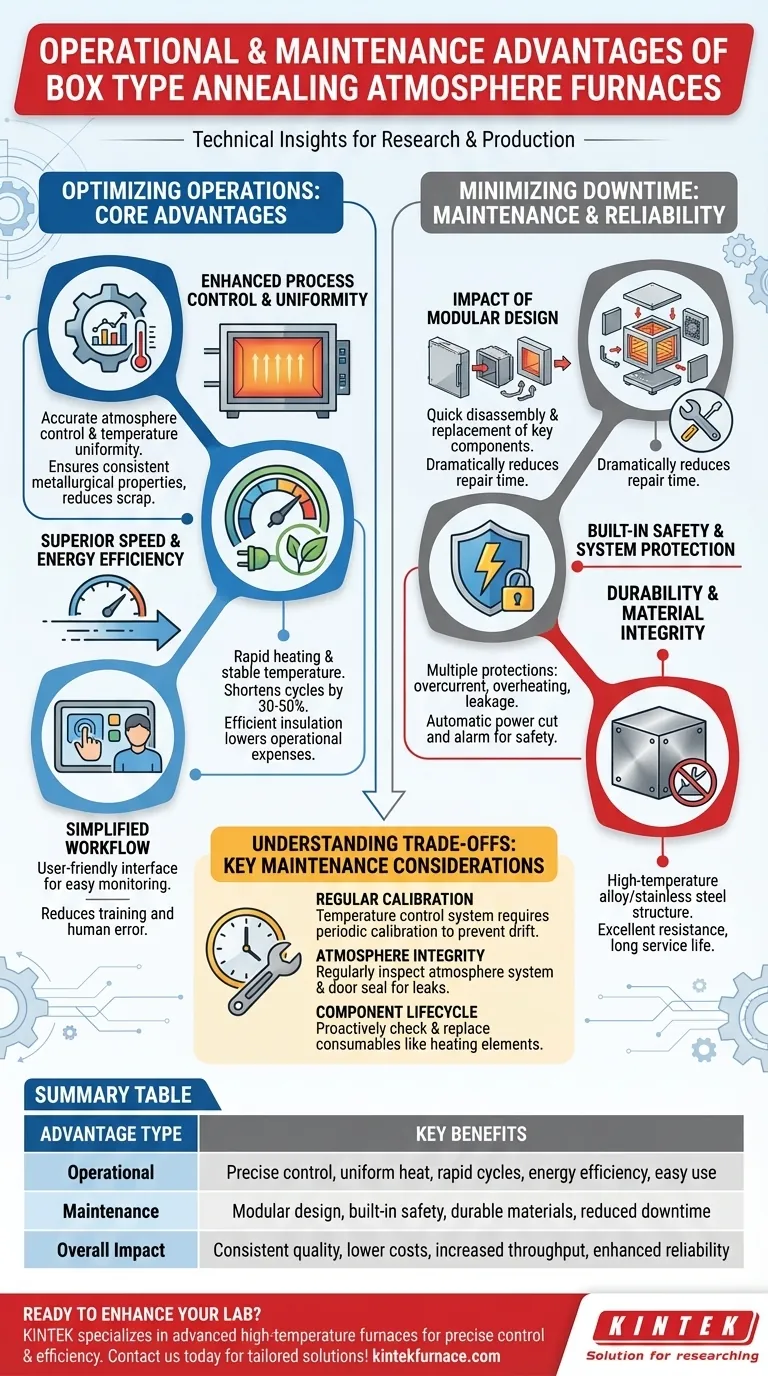

Optimizing Your Operations: The Core Advantages

A furnace's value is measured by its ability to perform its function reliably and efficiently. The box type design excels by focusing on key operational metrics that directly impact your process outcomes and bottom line.

Enhanced Process Control and Uniformity

The furnace provides accurate atmosphere control and good temperature uniformity. This precision is critical for achieving consistent metallurgical properties in treated materials, reducing scrap rates, and ensuring parts meet strict specifications.

Superior Speed and Energy Efficiency

These furnaces are engineered for rapid heating and stable temperature maintenance. This can shorten annealing cycles by 30% to 50% compared to traditional designs, directly increasing throughput. Efficient insulation and precise controls also minimize wasted energy, lowering operational expenses.

Simplified Operator Workflow

A user-friendly interface for setting and monitoring parameters is a key operational advantage. This reduces the training burden on operators and minimizes the risk of human error, leading to a more stable and predictable production environment.

Minimizing Downtime: Maintenance and Reliability

Downtime is a critical cost driver in any production or research setting. The design of a box type atmosphere furnace directly addresses this through features that enhance reliability and simplify service.

The Impact of Modular Design

The furnace's modular construction is its most significant maintenance advantage. It allows for the quick disassembly, replacement, and servicing of key components. This design philosophy dramatically reduces the time required for repairs, getting the equipment back online faster.

Built-in Safety and System Protection

Reliability is intrinsically linked to safety. These furnaces incorporate multiple protection devices, including overcurrent, overvoltage, overheating, and leakage protection. In an abnormal event, the system can automatically cut power and issue an alarm, protecting both the equipment and personnel. A reliable door seal also prevents hazardous atmosphere leakage.

Durability and Material Integrity

The furnace structure is typically built from high-temperature alloy steel or stainless steel. This choice of materials provides excellent resistance to both high temperatures and corrosion, ensuring a long service life and reducing the frequency of major structural repairs.

Understanding the Trade-offs: Key Maintenance Considerations

While advantageous, these furnaces are not "set-it-and-forget-it" systems. Their reliability is contingent on a disciplined approach to preventative maintenance.

The Necessity of Regular Calibration

To maintain process accuracy, the temperature control system requires periodic calibration. Drifts in sensor readings can lead to inconsistent treatment results, negating the benefits of the furnace's precise design.

Atmosphere System Integrity

The atmosphere control system and furnace door seal must be regularly inspected and maintained. Leaks not only compromise the treatment process but also pose a significant safety risk and waste expensive process gases.

Component Lifecycle Management

Key components like heating elements are consumables with a finite lifespan. Proactively checking their working status and planning for their eventual replacement is essential to avoid unexpected and prolonged downtime.

Making the Right Choice for Your Process

Selecting the right furnace depends on a clear understanding of your primary objectives.

- If your primary focus is process repeatability and quality: The furnace's precise atmosphere and uniform temperature controls are your most critical advantages.

- If your primary focus is production throughput and efficiency: The rapid heating cycles and reduced energy consumption will deliver the most significant impact on your output.

- If your primary focus is minimizing long-term operational costs: The modular design and durable construction reduce maintenance hours and extend the furnace's service life.

Ultimately, a well-maintained box type atmosphere furnace provides a predictable, reliable, and efficient platform for your heat treatment needs.

Summary Table:

| Advantage Type | Key Benefits |

|---|---|

| Operational | Precise atmosphere control, uniform temperature, rapid heating, energy efficiency, user-friendly interface |

| Maintenance | Modular design for easy servicing, built-in safety protections, durable materials, reduced downtime |

| Overall Impact | Consistent product quality, lower operating costs, increased throughput, enhanced reliability |

Ready to enhance your lab's heat treatment processes with reliable, high-performance solutions? KINTEK specializes in advanced high-temperature furnaces, including Box Type Annealing Atmosphere Furnaces, designed to deliver precise control, energy efficiency, and minimal downtime. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Contact us today to discuss how our tailored furnace solutions can optimize your operations and drive success!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the significance of using a muffle furnace to determine the ash content of biochar? Master Material Performance

- What is the role of a muffle furnace in synthesizing P2-Na0.67Ni0.33Mn0.67O2? Key to High-Performance Cathodes

- How is a laboratory muffle furnace utilized during the debinding stage of HAp green bodies? Precision Thermal Control

- Why is calcination essential for NaFePO4 phase formation? Engineering High-Performance Sodium Iron Phosphate

- How is a muffle furnace utilized for AlN crystal post-processing? Optimize Surface Purity via Staged Oxidation