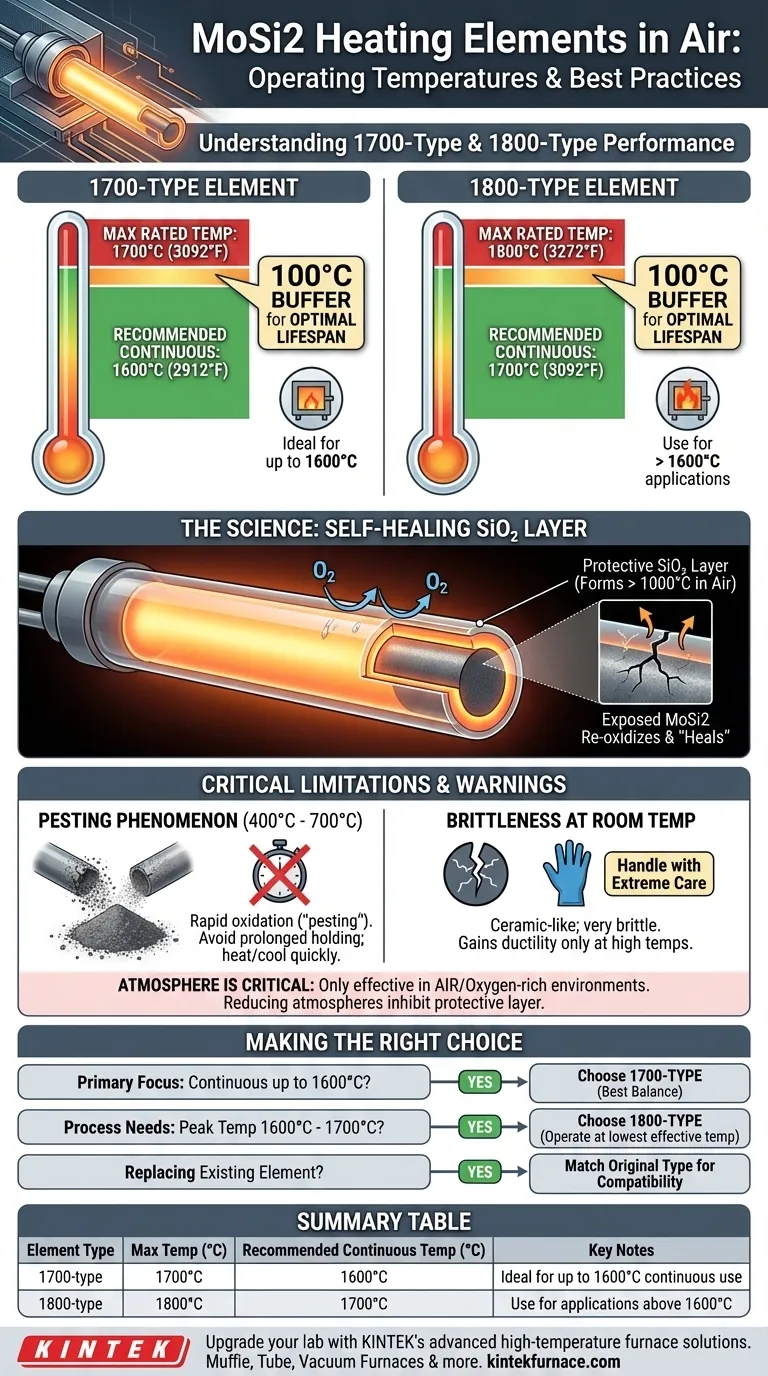

At their peak, a 1700-type Molybdenum Disilicide (MoSi2) heating element is designed for a maximum furnace temperature of 1700°C (3092°F) in air. Similarly, an 1800-type element is designed for a maximum of 1800°C (3272°F). However, for optimal lifespan and reliable performance, the recommended continuous operating temperature is typically 100°C lower than these maximum ratings.

The number on a MoSi2 element (e.g., "1700") signifies its maximum rated furnace temperature, not its ideal continuous working temperature. For long-term operational stability, it is standard practice to operate these elements approximately 100°C below their maximum rating.

The Science of MoSi2 High-Temperature Operation

To properly use these elements, it's crucial to understand the mechanism that allows them to survive such extreme heat. Their performance is not just about the material itself, but about a chemical reaction that happens at high temperatures.

The Self-Healing Protective Layer

The remarkable durability of MoSi2 elements comes from their ability to form a protective outer layer of pure silica (SiO2), which is essentially quartz glass. When heated in an oxygen-containing atmosphere (like air), the silicon in the element reacts with oxygen.

This thin, non-porous glass layer forms on the element's surface, preventing further oxidation of the underlying MoSi2 material. If a crack or flaw develops in this layer, the exposed material will immediately re-oxidize and "heal" the breach.

Temperature's Role in Layer Formation

This protective SiO2 layer only forms effectively at high temperatures, typically above 1000°C. Below this range, the material is vulnerable to other forms of oxidation. This is why MoSi2 elements are specifically designed for very high-temperature applications.

Distinguishing Maximum vs. Working Temperature

The most common point of confusion—and potential for premature failure—is the difference between the element's "type" and its recommended continuous operating temperature.

1700-Type Elements

A 1700-type element can achieve a maximum furnace temperature of 1700°C. However, its recommended continuous working temperature is 1600°C (2912°F). Operating within this lower range provides a critical buffer that dramatically extends the element's service life.

1800-Type Elements

An 1800-type element can reach a maximum furnace temperature of 1800°C. Its recommended continuous working temperature is 1700°C (3092°F). These are reserved for applications that absolutely require temperatures above 1600°C.

Why the Difference Matters

Continuously running an element at its absolute maximum temperature accelerates material degradation and significantly shortens its lifespan. The 100°C buffer zone is a well-established engineering practice that balances high performance with operational reliability and cost-effectiveness.

Understanding the Trade-offs and Limitations

While exceptional, MoSi2 elements are not without specific operational constraints. Ignoring these can lead to rapid failure.

The "Pesting" Phenomenon

In the low-temperature range of 400°C to 700°C, MoSi2 is highly susceptible to a form of accelerated oxidation known as "pesting." In this range, the material can rapidly disintegrate into a powder.

This is why furnaces using MoSi2 elements must be heated and cooled quickly through this temperature zone. They are not suitable for applications that require holding temperatures within this pesting range for extended periods.

Brittleness at Room Temperature

MoSi2 elements are ceramic-like and are very brittle at room temperature. They must be handled with extreme care during installation and maintenance to avoid fracture. They only gain ductility at very high temperatures.

Atmosphere Is Critical

The operating temperatures discussed here are valid only for operation in air or an oxygen-rich atmosphere. Using these elements in reducing or other controlled atmospheres will drastically alter their performance and maximum temperature capabilities, as it inhibits the formation of the protective silica layer.

Making the Right Choice for Your Application

Selecting the correct element type is a balance between your temperature requirements and your goal for operational longevity.

- If your primary focus is continuous operation up to 1600°C: Choose the 1700-type element for the best balance of high performance and long-term reliability.

- If your process requires peak temperatures between 1600°C and 1700°C: The 1800-type element is the correct choice, but plan to operate it at the lowest temperature that meets your process needs.

- If you are replacing elements in an existing furnace: Always use the same type originally specified for the furnace to ensure compatibility with the power controller and other system components.

Choosing the right element and operating it within its recommended working range is the key to achieving both high heat and a long service life.

Summary Table:

| Element Type | Max Temperature (°C) | Recommended Continuous Temperature (°C) | Key Notes |

|---|---|---|---|

| 1700-type | 1700°C | 1600°C | Ideal for up to 1600°C continuous use |

| 1800-type | 1800°C | 1700°C | Use for applications above 1600°C |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, enhancing efficiency and performance. Contact us today to discuss how we can support your high-temperature applications!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights