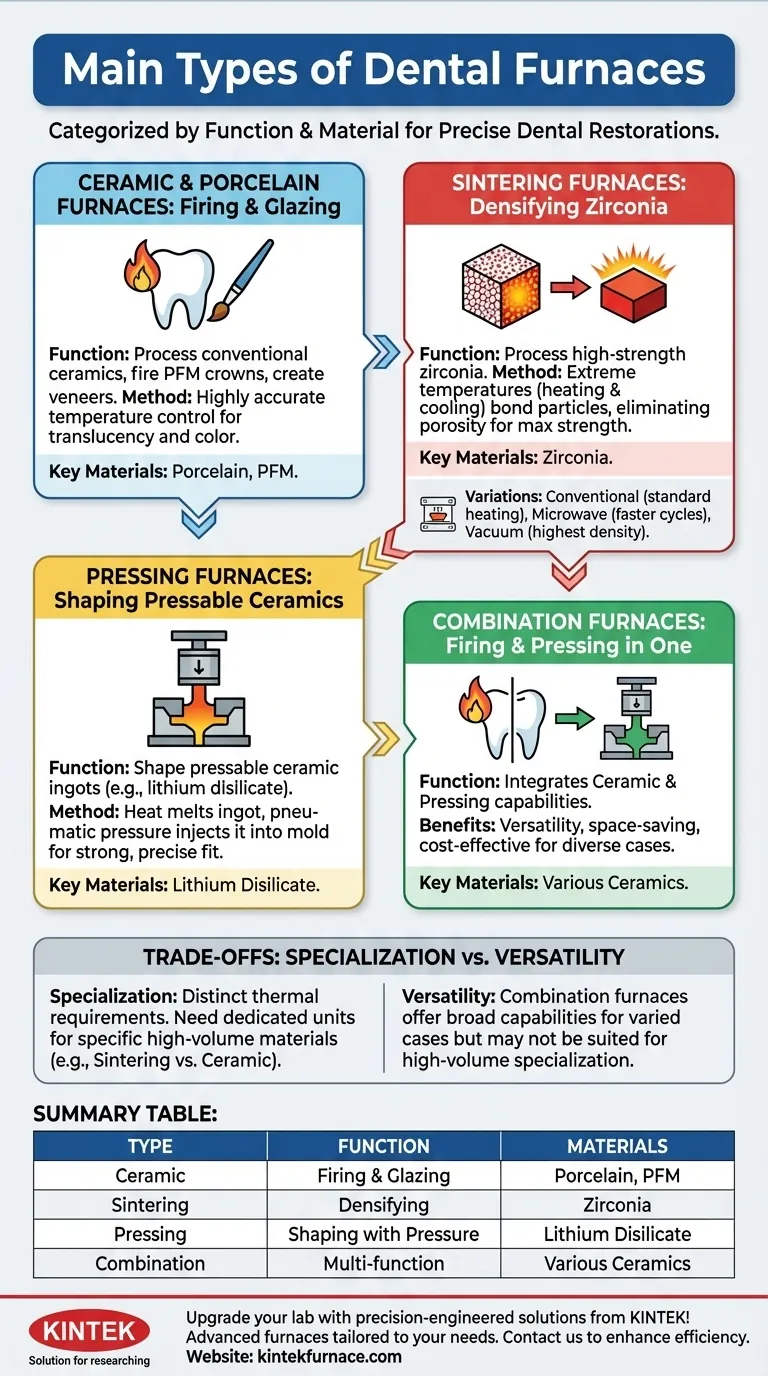

In short, the main types of dental furnaces are categorized by their function: ceramic furnaces for firing and glazing porcelain, sintering furnaces for processing high-strength materials like zirconia, and pressing furnaces for shaping pressable ceramics. Many modern labs also use combination furnaces that merge these capabilities.

The specific type of furnace a dental lab requires is determined entirely by the material being used. Each furnace is engineered to provide a precise combination of temperature, time, and sometimes pressure needed to transform a raw material into a final, durable dental restoration.

Understanding the Core Functions: Material Defines the Method

A dental furnace is not a one-size-fits-all oven. The fundamental differences between furnace types are rooted in the materials they are designed to process. Each material—be it zirconia, porcelain, or lithium disilicate—has a unique thermal profile required to achieve its final strength, fit, and aesthetic properties.

The Workhorse: Ceramic & Porcelain Furnaces

What They Do: Firing and Glazing These furnaces are the cornerstone of aesthetic dentistry, used for processing conventional ceramics. Their primary tasks are firing porcelain-fused-to-metal (PFM) crowns and creating lifelike, all-ceramic restorations like veneers.

How They Work: Precision and Aesthetics Ceramic furnaces operate at a lower temperature range compared to sintering furnaces. Their main advantage is highly accurate temperature control, which is critical for achieving the correct translucency, color matching, and a smooth, glazed surface on the final restoration.

The High-Heat Specialist: Sintering Furnaces

What They Do: Densifying Zirconia Sintering furnaces are built for one primary purpose: to process high-strength ceramic materials, most notably zirconia. In its pre-sintered state, zirconia is soft and chalk-like. This furnace subjects it to extreme temperatures to shrink and densify it into its final, incredibly strong form.

How They Work: Extreme Temperatures These units reach much higher temperatures than ceramic furnaces. The sintering cycle is a carefully controlled process of heating and cooling that bonds the ceramic particles together, eliminating porosity and ensuring maximum strength.

Key Sintering Technologies There are a few variations of this technology. Conventional furnaces use standard heating elements and are the most common. Microwave furnaces use microwave energy for significantly faster cycle times, while vacuum furnaces reduce atmospheric interference for the highest possible material density.

The Pressure Player: Pressing Furnaces

What They Do: Shaping Pressable Ceramics Pressing furnaces are designed for pressable ceramic materials, such as lithium disilicate. These materials come in the form of small ingots.

How They Work: Heat and Pneumatic Pressure This furnace heats the ceramic ingot until it becomes molten. It then uses pneumatic pressure to inject the viscous ceramic into a mold created from a burned-out wax pattern. This process is essential for creating strong, monolithic restorations with a precise fit.

The Hybrid Solution: Combination Furnaces

What They Do: Firing and Pressing in One As the name implies, a combination furnace integrates the functions of a ceramic furnace and a pressing furnace into a single unit. This versatility allows labs to fire standard porcelain crowns and also press all-ceramic restorations without needing two separate machines.

Who It's For: Labs Seeking Flexibility These units are ideal for dental labs that handle a diverse range of restorative cases. They offer a space-saving and cost-effective solution for practices or labs that need broad capabilities rather than high-volume specialization in a single area.

Understanding the Trade-offs: Specialization vs. Versatility

Choosing a furnace involves balancing specific needs against budget and workflow. No single furnace is universally superior; it's about finding the right tool for the job.

The Need for Specialization

A sintering furnace cannot be used to fire or glaze conventional porcelain, and a standard ceramic furnace cannot reach the temperatures required to sinter zirconia. The distinct thermal and procedural requirements of these materials demand specialized equipment.

The Cost of Advanced Technology

While furnaces like microwave or vacuum sintering units offer benefits in speed and final material quality, they come with a significantly higher initial investment. They also may require more specialized training to operate and maintain correctly.

The Limits of Versatility

A combination furnace is an excellent jack-of-all-trades, but it may be a master of none. A high-volume lab that produces hundreds of zirconia crowns daily will be better served by multiple, dedicated sintering furnaces to maximize throughput.

Selecting the Right Furnace for Your Lab

Your decision should be guided by the types of restorations you produce most often.

- If your primary focus is aesthetic porcelain work (veneers, PFM): A dedicated ceramic/porcelain furnace is the essential tool for optimal esthetics.

- If your primary focus is high-strength zirconia restorations: A dedicated sintering furnace is non-negotiable to achieve proper material strength.

- If your primary focus is pressable ceramics (e.g., lithium disilicate): A pressing furnace is the correct and only tool for this process.

- If you run a versatile lab with varied case types: A combination press-and-fire furnace offers the best balance of capability and efficiency.

Ultimately, aligning the furnace's function with your lab's specific material workflow is the key to producing consistent, high-quality dental restorations.

Summary Table:

| Type of Dental Furnace | Primary Function | Key Materials Processed |

|---|---|---|

| Ceramic Furnace | Firing and glazing | Porcelain, PFM |

| Sintering Furnace | Densifying | Zirconia |

| Pressing Furnace | Shaping with pressure | Lithium disilicate |

| Combination Furnace | Multi-function | Various ceramics |

Upgrade your dental lab with precision-engineered furnace solutions from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnaces tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization to meet unique experimental requirements. Whether you specialize in zirconia sintering, porcelain firing, or versatile ceramic work, we have the right furnace for you. Contact us today to enhance your lab's efficiency and quality!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique