At its core, the world of dental furnaces is divided into three primary categories based on the materials they process: conventional ceramic furnaces, combination (press) furnaces, and sintering furnaces. Each type is engineered for a specific thermal process, and using the wrong furnace for a given material will result in a complete failure of the restoration.

The choice of a dental furnace is not a matter of preference but a direct function of the dental materials you intend to use. Each furnace type is designed for a specific temperature range and process—firing conventional porcelain, pressing glass-ceramics, or sintering high-strength zirconia.

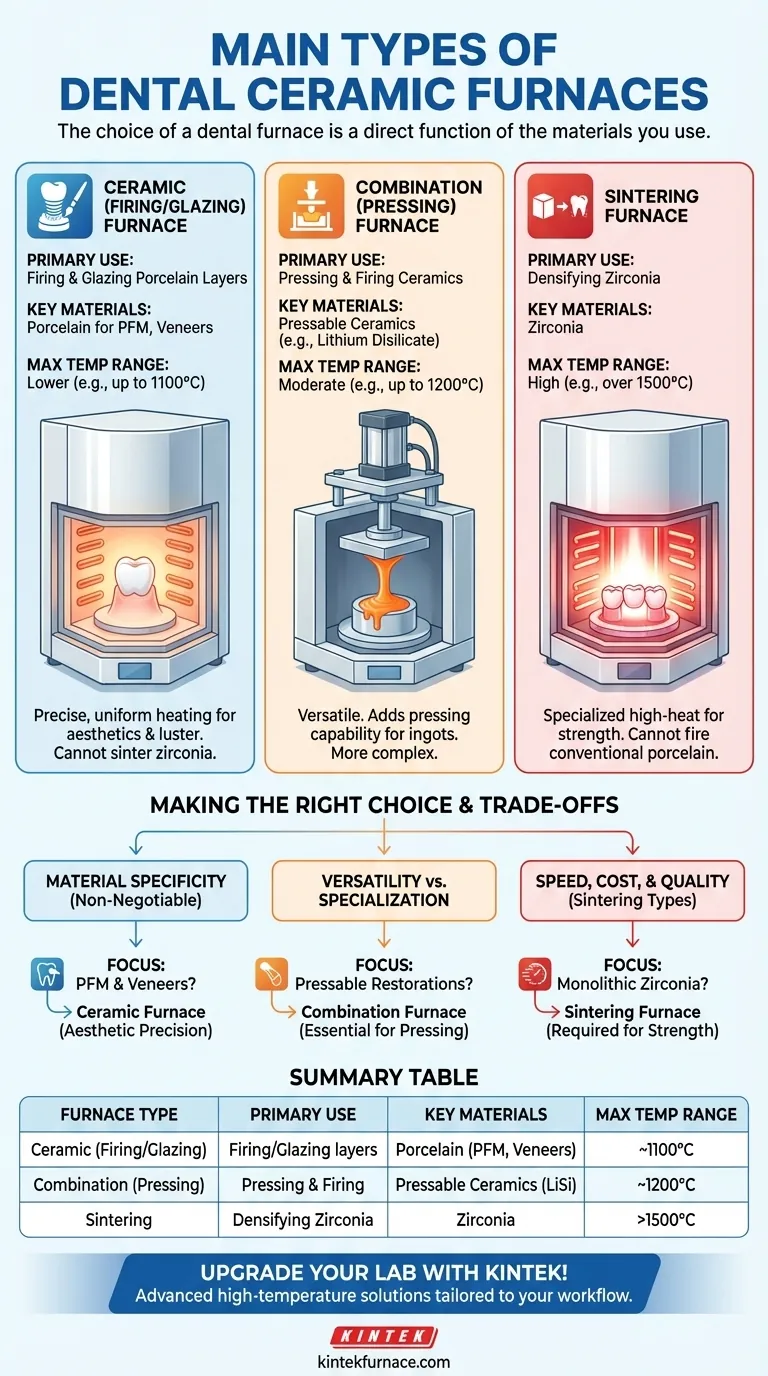

The Three Core Furnace Types Explained

Understanding the function of each furnace is critical to equipping a dental laboratory for success. The differences lie in their maximum temperature, pressure capabilities, and intended application.

Ceramic (Firing/Glazing) Furnaces

A ceramic furnace is the workhorse for traditional porcelain work. Its primary role is to fire layers of porcelain onto metal or ceramic substructures, as seen in porcelain-fused-to-metal (PFM) crowns and veneers.

These furnaces operate at lower temperatures compared to sintering units. They excel at providing the precise, uniform heating required to achieve optimal aesthetics, such as translucency and accurate color matching. They also handle the final glazing cycles that give restorations a lifelike luster.

Combination (Pressing) Furnaces

A combination furnace, often called a press furnace, expands on the capabilities of a standard ceramic furnace. It can perform all the firing and glazing cycles for conventional porcelains, but its key feature is the addition of a pressing mechanism.

This function is essential for creating restorations from pressable ceramic ingots, such as lithium disilicate. The furnace heats the ceramic ingot until it becomes viscous, then uses pneumatic or mechanical pressure to press it into a mold, forming a highly accurate and durable restoration.

Sintering Furnaces

Sintering furnaces are specialized, high-temperature units designed almost exclusively for processing zirconia. Zirconia restorations are initially milled from a soft, chalk-like, pre-sintered block.

The sintering furnace then subjects the material to extremely high temperatures (often exceeding 1500°C), causing the zirconia particles to fuse and densify. This process shrinks the restoration to its final dimensions and transforms it into an incredibly strong, monolithic structure. These furnaces cannot be used for conventional porcelains.

Understanding the Trade-offs

Selecting a furnace involves balancing material needs, workflow efficiency, and budget. Making an uninformed choice can be a costly mistake.

Material Specificity is Non-Negotiable

You cannot sinter zirconia in a conventional ceramic furnace. The temperatures required for sintering would destroy a standard firing furnace, whose heating elements (often Kanthal or Nichrome) are not designed for such extremes. Likewise, the lower temperatures of a ceramic furnace will do nothing to sinter a zirconia crown.

Versatility vs. Specialization

A combination furnace offers the greatest versatility, allowing a lab to handle both layered porcelains and pressable ceramics. However, if a lab does not work with pressable materials, the added cost and complexity are unnecessary. A dedicated sintering furnace is an absolute requirement for any practice or lab that produces its own zirconia restorations.

Speed, Cost, and Quality

Within the category of sintering furnaces, further trade-offs exist. Conventional sintering furnaces are the most common and affordable but have longer cycle times. Microwave sintering furnaces are faster and more energy-efficient but come with a higher initial investment. Vacuum furnaces can produce the highest quality restorations with less porosity but are the most expensive and require specialized operation.

Making the Right Choice for Your Goal

Your decision should be guided by the specific types of restorations your practice or laboratory produces.

- If your primary focus is PFM and layered veneers: A standard ceramic furnace provides the precise, lower-temperature firing cycles necessary for aesthetic excellence.

- If your primary focus is pressable restorations (e.g., lithium disilicate): A combination (press) furnace is essential, giving you the ability to both press and characterize restorations.

- If your primary focus is monolithic zirconia crowns and bridges: A dedicated high-temperature sintering furnace is the only suitable choice to achieve proper material strength and density.

Matching the furnace technology to the material is the foundational step in producing predictable, durable, and aesthetic dental restorations.

Summary Table:

| Furnace Type | Primary Use | Key Materials | Max Temperature Range |

|---|---|---|---|

| Ceramic (Firing/Glazing) | Firing and glazing porcelain layers | Porcelain for PFM, veneers | Lower temperatures (e.g., up to 1100°C) |

| Combination (Pressing) | Pressing and firing ceramics | Pressable ceramics (e.g., lithium disilicate) | Moderate temperatures (e.g., up to 1200°C) |

| Sintering | Densifying zirconia | Zirconia | High temperatures (e.g., over 1500°C) |

Upgrade your dental lab with the perfect furnace solution! Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need a ceramic, combination, or sintering furnace, we can tailor it to your specific material and workflow needs. Contact us today to discuss how our furnaces can enhance your restoration quality and efficiency!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab