The choice of a heating element alloy is governed by a precise balance of electrical, thermal, and mechanical properties. The most common alloys used for manufacturing heating elements are Nickel-Chromium (NiCr), known for its all-around performance; Iron-Chrome-Aluminum (FeCrAl), valued for its high-temperature capabilities and lower cost; and Copper-Nickel (CuNi), which is used for precise heating at lower temperatures. Specialized applications may also use platinum or refractory metals for extreme conditions.

Selecting the right alloy is not merely about its melting point; it's a critical engineering decision that balances maximum operating temperature, resistance to oxidation, and cost. The material must efficiently convert electricity into heat while surviving its harsh operating environment.

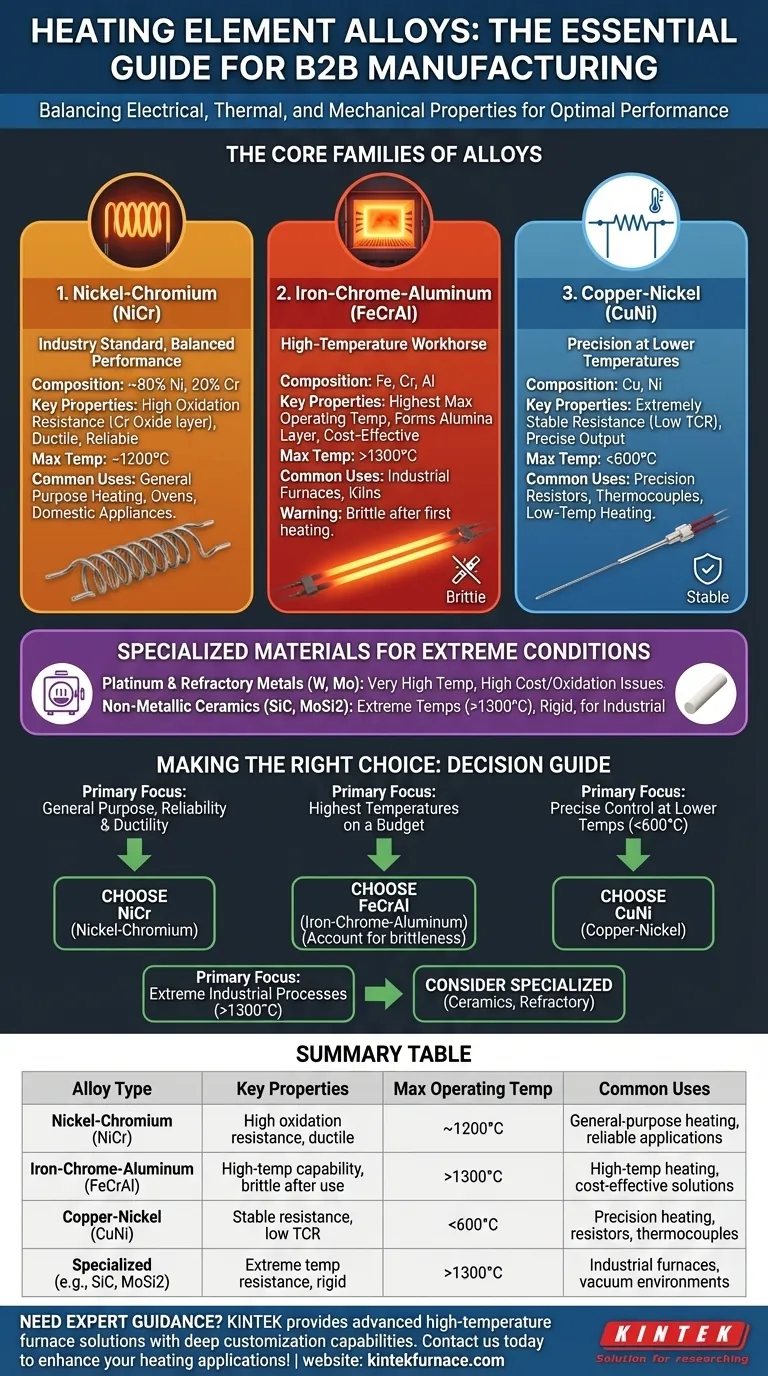

The Core Families of Heating Element Alloys

The vast majority of resistive heating applications are served by three primary alloy families. Each offers a distinct set of properties tailored to different operating conditions and performance requirements.

Nickel-Chromium (NiCr) Alloys: The Industry Standard

The most well-known of these alloys is Nichrome, typically composed of 80% nickel and 20% chromium. This family is the benchmark for heating elements due to its superb balance of properties.

When heated, the chromium on the alloy's surface forms a protective, adherent layer of chromium oxide. This layer prevents oxygen from reaching the metal underneath, dramatically slowing down oxidation and extending the element's life.

NiCr alloys are also highly ductile, meaning they can be easily drawn into wire or formed into coils and complex shapes without fracturing. They maintain this mechanical integrity even after repeated thermal cycles.

Iron-Chrome-Aluminum (FeCrAl) Alloys: The High-Temperature Workhorse

Commonly known by the trade name Kanthal, FeCrAl alloys are the primary alternative to NiCr. Their key advantage is a higher maximum operating temperature than most NiCr alloys, often exceeding 1300°C (2372°F).

This performance is thanks to the aluminum in the alloy, which forms a very stable and protective layer of aluminum oxide (alumina) at high temperatures. These alloys are also generally less expensive than their nickel-based counterparts.

However, this high-temperature performance comes with a trade-off. After their first heating, FeCrAl alloys become very brittle and can easily break if subjected to mechanical shock or vibration.

Copper-Nickel (CuNi) Alloys: Precision at Lower Temperatures

Also known as Constantan, this alloy family is designed for a different purpose. Its defining characteristic is a very low temperature coefficient of resistance (TCR).

This means its electrical resistance remains remarkably stable across a wide range of temperatures. While it cannot be used for high-temperature heating (typically limited to below 600°C / 1112°F), it is ideal for applications requiring predictable and precise output.

You will find CuNi alloys in precision resistors, thermocouples, and heating applications where exact wattage output is more critical than raw heat.

Specialized Materials for Extreme Conditions

For applications that push beyond the limits of conventional alloys, engineers turn to more exotic materials.

Platinum and Refractory Metals

Platinum offers outstanding resistance to oxidation and chemical corrosion at very high temperatures, but its extremely high cost limits its use to highly specialized lab equipment and sensors.

Tungsten and Molybdenum have exceptionally high melting points but oxidize catastrophically in open air. They are reserved for use in vacuum furnaces or environments with a protective, inert atmosphere.

Non-Metallic Ceramic Elements

For the most demanding industrial furnaces and kilns, non-metallic materials are required. Silicon Carbide (SiC) and Molybdenum Disilicide (MoSi2) are ceramics that can operate continuously at temperatures far beyond the capabilities of any metal alloy. They are rigid, self-healing, and designed for extreme industrial environments.

Understanding the Critical Trade-offs

Choosing an alloy is a matter of prioritizing performance characteristics. No single material is perfect for every situation.

Oxidation Resistance vs. Brittleness

Both NiCr and FeCrAl alloys rely on a protective oxide layer for survival. The chromium oxide on NiCr is highly effective and allows the underlying metal to remain ductile.

The aluminum oxide on FeCrAl provides superior temperature protection but fundamentally changes the alloy's mechanical properties, making it brittle and fragile once used.

Operating Temperature vs. Cost

There is a clear hierarchy. CuNi alloys are for lower temperatures. NiCr alloys represent the reliable, high-performance middle ground. FeCrAl alloys push the temperature ceiling higher for a moderate cost.

Platinum, refractory metals, and ceramic elements provide ultimate temperature performance but at a significantly higher material and operational cost.

Resistivity and Stability

A good heating element needs high electrical resistance to generate heat efficiently (P = I²R). Both NiCr and FeCrAl offer high resistivity suitable for high-power elements.

However, for applications where output must be constant as the element heats up, the low TCR of a CuNi alloy is the most important factor, even though its overall resistivity is lower.

Making the Right Choice for Your Application

Your final decision will depend entirely on your primary engineering goal.

- If your primary focus is general-purpose heating with high reliability: Choose a Nickel-Chromium (NiCr) alloy for its excellent balance of oxidation resistance, cost, and ductility.

- If your primary focus is reaching the highest possible temperatures on a budget: An Iron-Chrome-Aluminum (FeCrAl) alloy is the superior choice, but you must account for its post-heating brittleness in your design.

- If your primary focus is precise wattage control at lower temperatures (below 600°C): A Copper-Nickel (CuNi) alloy is ideal due to its exceptionally stable resistance across its operating range.

- If your primary focus is extreme-temperature industrial processes (above 1300°C): You must look beyond traditional alloys to non-metallic elements like Silicon Carbide (SiC) or Molybdenum Disilicide (MoSi2).

Understanding these core material properties empowers you to select an element that delivers not just heat, but also the reliability and longevity your project demands.

Summary Table:

| Alloy Type | Key Properties | Max Operating Temp | Common Uses |

|---|---|---|---|

| Nickel-Chromium (NiCr) | High oxidation resistance, ductile | ~1200°C | General-purpose heating, reliable applications |

| Iron-Chrome-Aluminum (FeCrAl) | High-temperature capability, brittle after use | >1300°C | High-temp heating, cost-effective solutions |

| Copper-Nickel (CuNi) | Stable resistance, low TCR | <600°C | Precision heating, resistors, thermocouples |

| Specialized (e.g., SiC, MoSi2) | Extreme temp resistance, rigid | >1300°C | Industrial furnaces, vacuum environments |

Need expert guidance on selecting the perfect heating element alloy for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet unique experimental requirements—ensuring optimal performance, reliability, and cost-efficiency. Contact us today to discuss how our tailored solutions can enhance your heating applications!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions