At its core, a porcelain furnace is built from four fundamental components. These are a high-temperature heating element, a precision temperature controller, a firing chamber to hold the work, and a system for controlled cooling. Advanced models also integrate a vacuum system. These parts work in concert to execute highly specific heating and cooling cycles, transforming ceramic powders into strong, aesthetic dental restorations.

The ultimate goal of a porcelain furnace is not simply to generate heat, but to execute complex, multi-stage firing programs with absolute consistency. Understanding its components reveals how it achieves the precise control necessary to develop the exact physical and aesthetic properties required for modern dental materials.

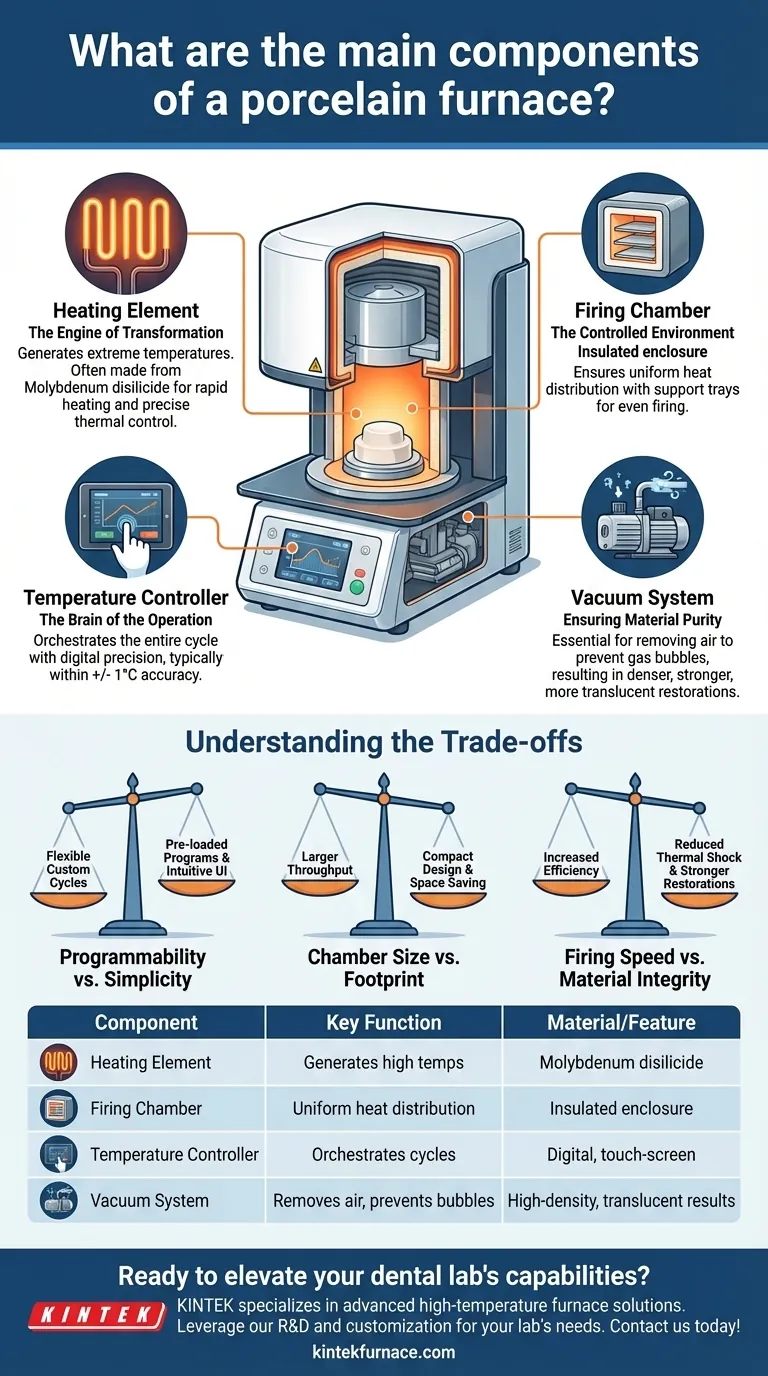

The Anatomy of a Porcelain Furnace

Each component plays a distinct and critical role in the firing process. The quality and integration of these parts determine the furnace's accuracy, reliability, and the final quality of the dental restoration.

The Heating Element: The Engine of Transformation

The heating element is responsible for generating the extreme temperatures required for sintering dental ceramics. It is the workhorse of the furnace.

These elements are typically made from molybdenum disilicide, a material chosen for its ability to withstand incredibly high temperatures and heat up rapidly. This allows the furnace to follow the programmed temperature changes with precision.

The Firing Chamber: The Controlled Environment

The firing chamber, or muffle, is the insulated enclosure where dental restorations are placed for firing. Its design is critical for ensuring consistent results.

A well-designed chamber provides uniform heat distribution, eliminating hot or cold spots that could compromise the restoration. Restorations are placed on ceramic or metal support trays within this chamber to allow for even heating.

The Temperature Controller: The Brain of the Operation

The temperature controller is the electronic brain that orchestrates the entire firing cycle. It dictates exactly how the heating element behaves.

Modern furnaces feature digital controllers with touch-screen interfaces that allow technicians to program every stage of the cycle, including the rate of temperature increase (ramp), the holding time at peak temperature (soak), and the cooling rate. High-end models maintain accuracy within +/- 1°C, a crucial factor for sensitive ceramic materials.

The Vacuum System: Ensuring Material Purity

Many high-quality porcelain furnaces include a vacuum pump. This is not a secondary feature; it is essential for creating high-density, low-porosity restorations.

By removing air from the chamber during the heating cycle, the vacuum system prevents gas bubbles from being trapped within the ceramic. This results in a stronger, denser, and more translucent final restoration, which is critical for aesthetic outcomes.

Understanding the Trade-offs

Choosing or operating a furnace involves balancing several key factors. Understanding these trade-offs is essential for matching the equipment to the task.

Programmability vs. Simplicity

Some furnaces come with hundreds of open programs and USB connectivity for custom cycles, ideal for research or specialty labs. Others offer a simpler interface with pre-loaded programs for the most common materials. More programs offer flexibility but can introduce complexity.

Chamber Size vs. Footprint

A larger firing chamber can process more restorations at once, increasing throughput. However, this comes at the cost of a larger physical footprint and potentially higher energy consumption. A compact design is often a priority for labs where space is at a premium.

Firing Speed vs. Material Integrity

While rapid firing cycles can increase lab efficiency, they can also induce thermal shock and stress in the ceramic. The furnace's capability for speed must be carefully matched with the specific ceramic manufacturer's instructions to avoid compromising the restoration's strength and longevity.

Making the Right Choice for Your Needs

Your specific goals should dictate which furnace features you prioritize.

- If your primary focus is routine production of PFM or zirconia: A furnace with reliable temperature control and a durable heating element is more critical than extensive custom programming.

- If your primary focus is advanced aesthetics and complex materials: Prioritize a furnace with a high-precision controller, a robust vacuum system, and deep programmability to handle sensitive materials.

- If your primary focus is in-office efficiency: Look for a furnace with a compact design, an intuitive user interface, and pre-loaded programs for common materials to minimize the learning curve.

Ultimately, understanding these components empowers you to select and operate a furnace not just as a machine, but as a precision instrument for creating exceptional dental restorations.

Summary Table:

| Component | Key Function | Material/Feature |

|---|---|---|

| Heating Element | Generates high temperatures for sintering | Molybdenum disilicide for rapid heating |

| Firing Chamber | Provides uniform heat distribution | Insulated enclosure with support trays |

| Temperature Controller | Orchestrates firing cycles | Digital with touch-screen, +/- 1°C accuracy |

| Vacuum System | Removes air to prevent bubbles | Essential for high-density, translucent restorations |

Ready to elevate your dental lab's capabilities? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored for dental laboratories. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental and production needs, delivering consistent, high-quality results for porcelain restorations. Contact us today to discuss how our furnaces can optimize your workflow and enhance your restoration quality!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab