In advanced material synthesis, high-temperature vacuum furnaces are indispensable tools for a range of critical processes. They are used for the heat treatment of metals and alloys, the fabrication of electronic components like semiconductor wafers, the sintering of high-performance ceramics and medical implants, and the synthesis of novel materials such as carbon nanotubes and quantum dots. These applications span high-precision industries including aerospace, medicine, and electronics.

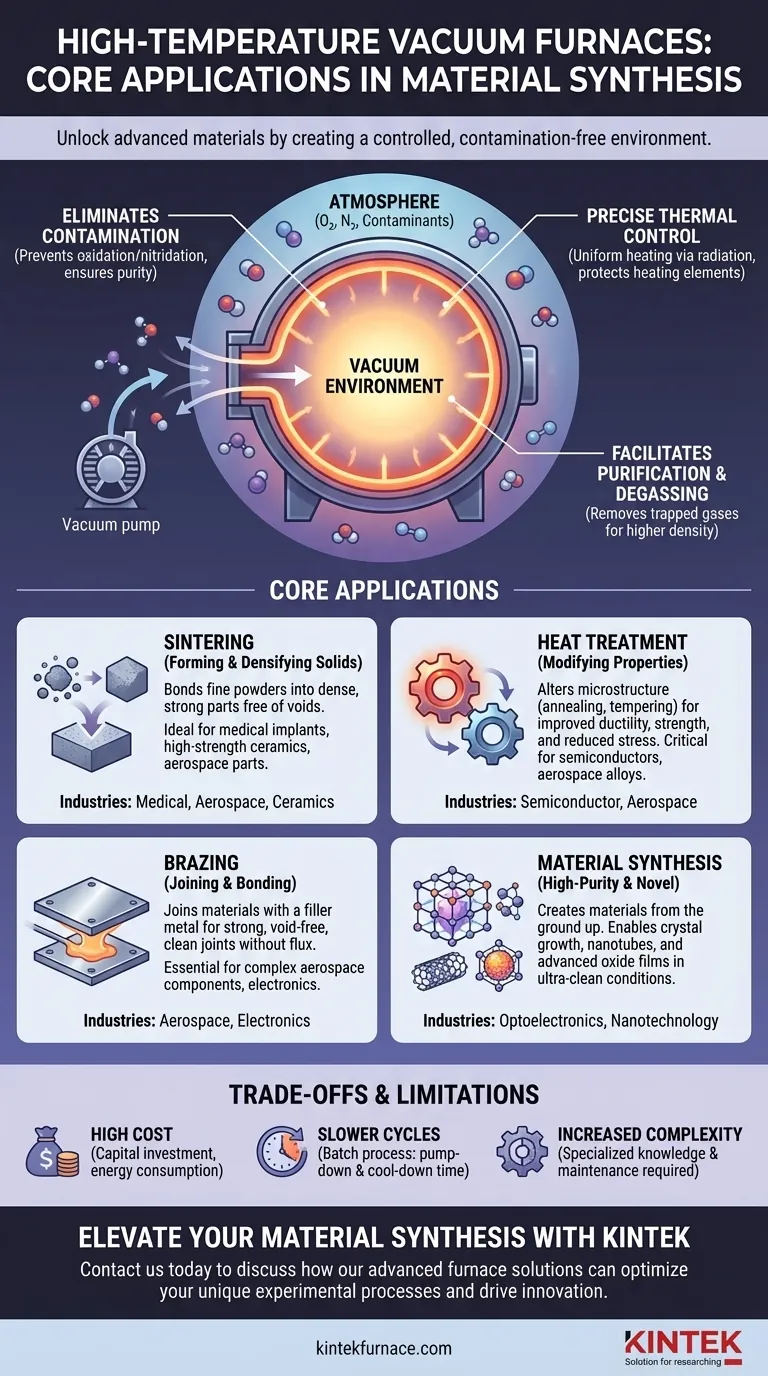

The core value of a high-temperature vacuum furnace is not just its ability to generate heat, but its power to create a controlled, contamination-free environment. By removing reactive atmospheric gases, these furnaces prevent unwanted oxidation and impurities, enabling the creation and refinement of materials with properties that would be unattainable in a standard atmosphere.

How Vacuum Enables Advanced Material Processing

To understand the applications, you must first understand the fundamental problem these furnaces solve: atmospheric contamination. At high temperatures, even trace amounts of oxygen or nitrogen react with materials, altering their chemical composition and degrading their performance.

Eliminating Contamination

A vacuum environment is essentially a pristine workbench. By removing atmospheric gases, the furnace prevents unwanted chemical reactions like oxidation and nitridation, which can compromise the structural integrity, conductivity, or purity of a material.

This is critical for reactive metals like titanium and for semiconductor materials where even parts-per-billion impurities can cause device failure.

Enabling Precise Thermal Control

In a vacuum, heat transfer occurs primarily through radiation, not convection. This allows for exceptionally uniform heating and cooling, preventing thermal stresses that can cause microscopic cracks or defects in sensitive components.

The controlled environment also protects the furnace's own high-temperature heating elements from burnout, allowing them to operate at extreme temperatures (above 1200°C) reliably.

Facilitating Purification and Degassing

The vacuum actively pulls trapped gases and volatile impurities out from within the bulk material, a process known as degassing. This results in a final product with higher density, fewer internal voids, and superior mechanical properties.

Core Applications in Synthesis and Preparation

Different processes leverage the vacuum environment to achieve specific material outcomes. These applications are foundational in both research and industrial production.

Forming and Densifying Solids (Sintering)

Sintering is the process of bonding fine powders together into a solid mass using heat, but without melting.

In a vacuum, sintering produces dense, strong parts free from the internal voids that can form when air is trapped. This is essential for manufacturing biocompatible medical implants, high-strength ceramic components, and metallic parts for aerospace.

Modifying Material Properties (Heat Treatment)

Heat treatment alters a material's microstructure to enhance its physical and mechanical properties.

Key processes include annealing, which softens materials to improve ductility and relieve internal stresses, and tempering, which increases toughness. These are vital for processing silicon wafers in the semiconductor industry and for optimizing the strength of aerospace alloys.

Joining and Bonding Materials (Brazing)

Vacuum brazing joins two or more materials using a filler metal that melts and flows between them.

The vacuum ensures a perfectly clean surface, allowing the filler metal to form an exceptionally strong, void-free joint without the need for corrosive chemical fluxes. This technique is standard for assembling complex aerospace components and electronic devices.

Synthesizing High-Purity and Novel Materials

The ultra-clean environment is ideal for creating materials from the ground up. This includes crystal growth for the semiconductor and artificial gem industries, where a single impurity can ruin the entire crystal lattice.

It also enables the synthesis of advanced materials like carbon nanotubes, quantum dots, and specialized oxide films for use in optoelectronics and nanomaterial research, where precise control over atomic structure is paramount.

Understanding the Trade-offs and Limitations

While powerful, vacuum furnaces are not a universal solution. Their benefits come with clear trade-offs that must be considered.

High Initial and Operational Cost

Vacuum furnaces, along with their required pumping systems and control instrumentation, represent a significant capital investment. They also consume substantial energy to both generate heat and maintain a high vacuum.

Slower Processing Cycles

Achieving a high vacuum is not instantaneous. The time required for the "pump-down" before heating and the controlled cool-down after the process is complete makes vacuum furnace operation a batch process, which is inherently slower than continuous atmospheric furnaces.

Increased Complexity and Maintenance

Operating and maintaining a high-vacuum system requires specialized knowledge. Seals, gaskets, and pumps require regular inspection and service to prevent leaks that would compromise the entire process.

Aligning the Process with Your Material Goal

Choosing the right furnace process depends entirely on your end goal. The vacuum environment is a powerful variable that can be tuned to achieve specific outcomes.

- If your primary focus is ultimate purity for electronics: Vacuum annealing, doping, and crystal growth are non-negotiable for creating semiconductor-grade wafers and optoelectronic components.

- If your primary focus is mechanical strength and integrity: Vacuum sintering and brazing are essential for producing void-free, high-strength parts for demanding aerospace, medical, or industrial applications.

- If your primary focus is novel material discovery: The pristine and controllable environment of a vacuum furnace is the ideal platform for synthesizing nanomaterials, advanced ceramics, and composites with unique properties.

Ultimately, a high-temperature vacuum furnace is the definitive tool for any application where material purity and structural integrity cannot be compromised.

Summary Table:

| Application | Key Process | Industries Benefited |

|---|---|---|

| Sintering | Bonding powders without melting | Medical implants, Aerospace, Ceramics |

| Heat Treatment | Annealing, tempering | Semiconductor, Aerospace |

| Brazing | Joining with filler metal | Aerospace, Electronics |

| Material Synthesis | Crystal growth, nanomaterial creation | Optoelectronics, Nanotechnology |

Elevate your material synthesis with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering contamination-free environments for superior purity and structural integrity in industries like aerospace, medicine, and electronics. Contact us today to discuss how our furnaces can optimize your processes and drive innovation!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics