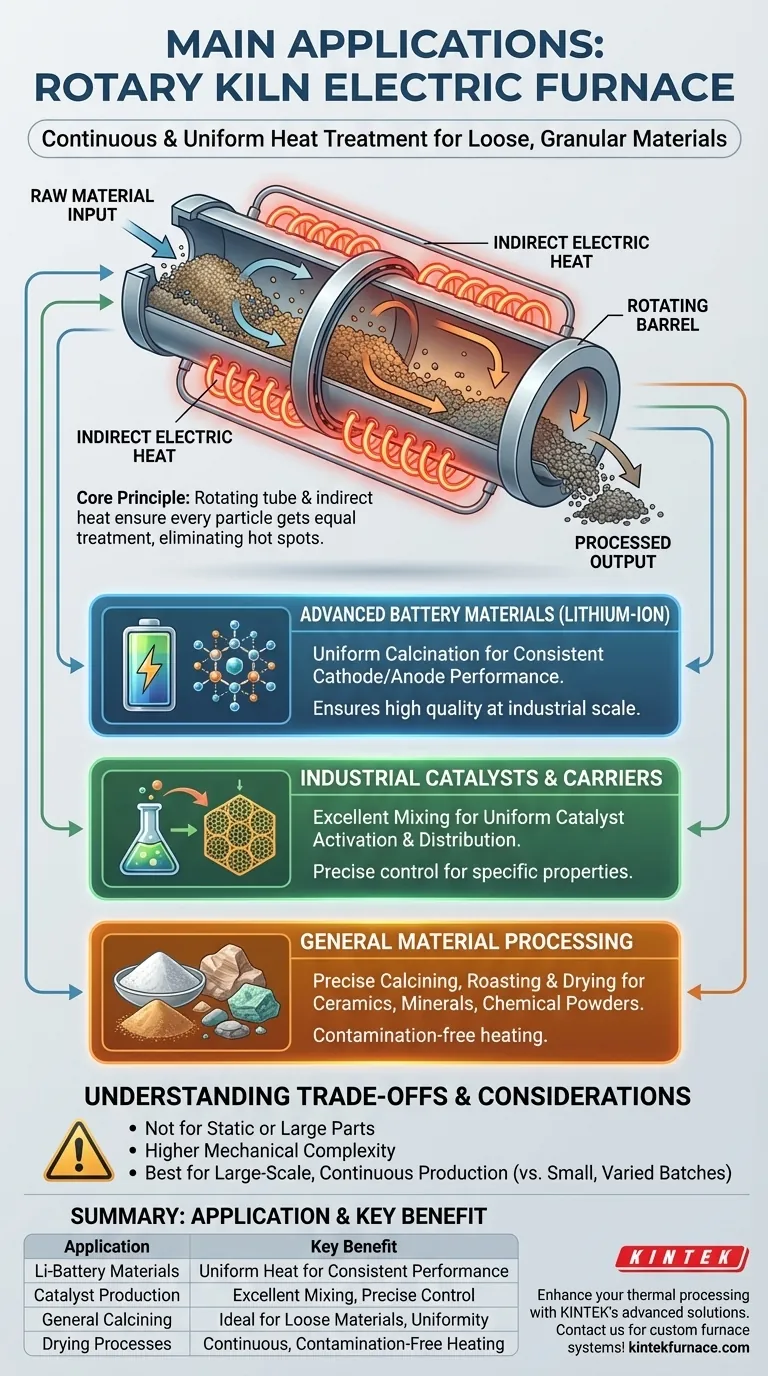

At its core, a rotary kiln electric furnace is a specialized tool for the continuous and highly uniform heat treatment of loose, granular materials. Its primary applications are found in advanced manufacturing sectors, particularly for producing lithium battery components and industrial catalysts, as well as for general calcining, roasting, and drying processes that demand precise temperature control and consistency.

The essential value of a rotary kiln electric furnace is not just its ability to heat materials, but its unique mechanism for ensuring every particle receives the exact same thermal treatment. This is achieved through continuous rotation and mixing, making it indispensable for high-performance materials where uniformity is non-negotiable.

How a Rotary Kiln Electric Furnace Achieves Unmatched Uniformity

Understanding the applications requires first understanding the operational principle. This furnace is not a simple static oven; its design is entirely centered on motion and control.

The Principle of Continuous Mixing

A rotary kiln consists of a long cylindrical tube, or barrel, that is slightly inclined and rotates slowly on its axis.

Raw material is fed into the higher end of the tube. As the tube rotates, the material tumbles and mixes, gradually moving down the incline toward the lower end.

This constant tumbling action is the key. It ensures that the material is thoroughly mixed and that every particle is exposed to the heat source evenly, eliminating hot spots and inconsistent processing.

The Advantage of Indirect Electric Heat

The heat is not generated inside the barrel with the material. Instead, electric heating elements are positioned outside the furnace tube.

This indirect heating prevents contamination of the material by combustion byproducts and allows for exceptionally precise temperature control.

The system can be designed with multiple independent heating zones along the length of the tube, allowing for a carefully controlled temperature profile as the material travels through the furnace.

Key Industrial Applications

The unique combination of continuous mixing and precise, clean heating makes the rotary kiln electric furnace the ideal choice for several demanding industrial processes.

Advanced Battery Materials

The production of cathode and anode materials for lithium-ion batteries is a primary application. These materials, often powders, require calcination at specific temperatures to achieve the desired crystal structure and electrochemical properties.

Inconsistency in heat treatment leads directly to inconsistent battery performance and reduced lifespan. The rotary kiln's ability to deliver exceptionally uniform heat treatment ensures high-quality, reliable battery materials at an industrial scale.

Catalyst and Catalyst Carrier Production

Rotary kilns are critical for roasting catalysts and their carriers. The performance of a catalyst is highly dependent on its physical and chemical properties, which are set during heat treatment.

The furnace's excellent mixing capabilities ensure that the active chemical species are uniformly distributed and activated. Its operational flexibility allows producers to fine-tune the process for different catalyst formulations and particle sizes.

General Material Processing

Beyond these specialized fields, the furnace is widely used for any process involving loose materials that requires calcining, roasting, or drying.

This includes the production of certain ceramics, the processing of minerals, and the thermal treatment of various chemical powders where consistent final properties are essential for product quality.

Understanding the Trade-offs

While powerful, the rotary kiln electric furnace is not a universal solution. Its specialized design comes with specific limitations.

Not for Static or Large Parts

This furnace is designed exclusively for powders, granules, and other loose materials. It is completely unsuitable for processing large, solid objects, components that must remain static, or materials that would melt and aggressively stick to the furnace walls.

Mechanical Complexity

The rotating mechanism, seals, and drive system make a rotary kiln more mechanically complex than a static box or tube furnace. This can translate to a higher initial investment and more demanding maintenance requirements.

Throughput vs. Flexibility

The continuous nature of a rotary kiln is a major advantage for large-scale, consistent production runs of a single material. However, it can be less efficient for small, varied batches often seen in research labs, where a simpler batch furnace would be more practical.

Making the Right Choice for Your Goal

Selecting the correct thermal processing equipment depends entirely on your material, your desired throughput, and your final quality requirements.

- If your primary focus is mass-producing high-performance powders like battery materials: The continuous processing and unparalleled uniformity of a rotary kiln electric furnace make it the superior choice.

- If your primary focus is developing or producing industrial catalysts: The excellent mixing and process control of a rotary kiln are essential for ensuring consistent catalytic activity.

- If your primary focus is general-purpose lab research with varied, small-batch samples: A simpler and more cost-effective static muffle or tube furnace is likely the more appropriate tool.

Ultimately, you choose a rotary kiln electric furnace when the uniformity of your final product is the single most critical factor for its performance.

Summary Table:

| Application | Key Benefit |

|---|---|

| Lithium Battery Materials | Ensures uniform heat treatment for consistent performance |

| Catalyst Production | Provides excellent mixing and precise temperature control |

| General Calcining/Roasting | Ideal for loose materials requiring high uniformity |

| Drying Processes | Offers continuous, contamination-free heating |

Upgrade your thermal processing with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems tailored to your needs. Our product line includes Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization capabilities to precisely meet unique experimental requirements. Whether you're mass-producing battery materials or developing catalysts, our expertise ensures optimal performance and efficiency. Contact us today to discuss how we can enhance your operations!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- What are the main components in the construction of a rotary kiln? A Guide to the Core Systems