The primary advantage of a retort furnace is its ability to create a highly controlled, isolated processing environment. This is achieved through a sealed chamber, known as a retort, which separates the material being treated from the furnace's heating elements and the outside air. This fundamental design leads to superior product purity by preventing oxidation, allows for a wide range of specialized heat treatments, and improves overall operational efficiency.

A retort furnace should be viewed not just as a heat source, but as a precision instrument. By physically separating the workload from the ambient environment, it gives engineers absolute control over the two most critical variables in materials processing: atmosphere and temperature.

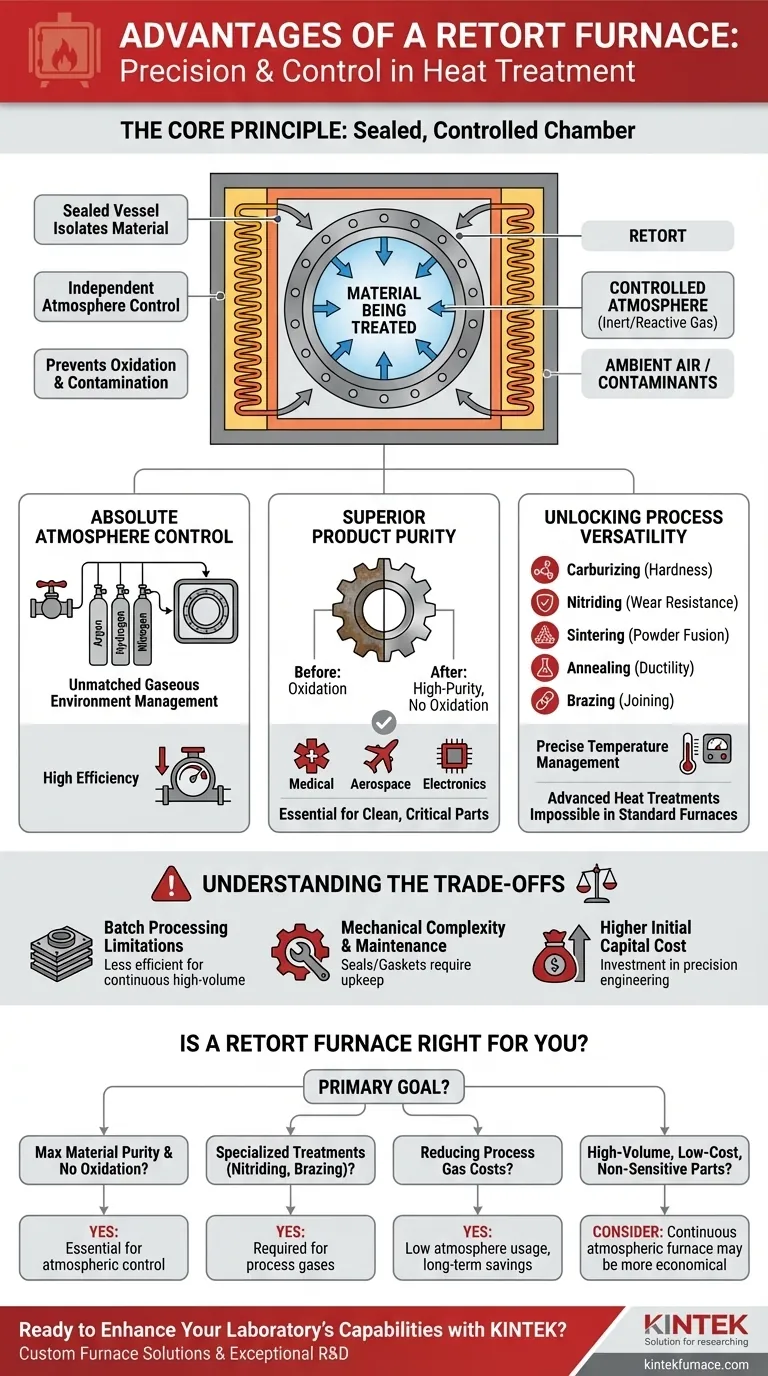

The Core Principle: A Sealed, Controlled Chamber

The defining feature of a retort furnace is the retort itself. Understanding this component is key to grasping all of its subsequent advantages.

What is a Retort?

A retort is a sealed vessel, typically made of metal alloy or ceramic, that holds the material being heat-treated. This entire vessel is then placed inside the furnace to be heated.

This design creates a completely isolated internal environment. The atmosphere inside the retort can be controlled independently of the air outside it.

Absolute Atmosphere Control

Because the retort is a closed system, it provides unmatched control over the gaseous environment surrounding the product. This prevents unwanted reactions with oxygen, moisture, and other contaminants present in the air.

This sealed design makes it highly efficient to introduce and maintain specialized process atmospheres, such as inert argon, reactive hydrogen, or nitrogen for nitriding.

The Impact on Product Purity

The direct result of precise atmosphere control is a significant increase in product quality. By preventing oxidation and contamination, retort furnaces are essential for producing clean, high-purity parts.

This is critical for applications in medical, aerospace, and electronics, where even microscopic levels of surface oxidation can lead to component failure.

Unlocking Process Versatility

The combination of a controlled atmosphere and precise temperature management makes retort furnaces exceptionally versatile.

Precise Temperature Management

Modern retort furnaces integrate sophisticated temperature control systems. When combined with the uniform heating environment inside the sealed chamber, these systems allow for extremely accurate and repeatable thermal cycles.

The furnace can be heated by either electric elements or gas burners, with the choice depending on the specific application and temperature requirements.

Enabling Advanced Heat Treatments

The ability to manipulate both temperature and atmosphere allows retort furnaces to perform a wide range of processes that are impossible in a standard atmospheric furnace.

Common applications include:

- Carburizing: Adding carbon to the surface of steel to increase hardness.

- Nitriding: Diffusing nitrogen into a metal's surface for wear resistance.

- Sintering: Fusing powdered materials together at high temperatures.

- Annealing: Altering a material's microstructure to improve ductility.

- Brazing: Joining metals using a filler metal in a clean, flux-free environment.

Understanding the Trade-offs

While powerful, retort furnaces are not the universal solution for all heating applications. Understanding their limitations is crucial for making an informed decision.

Batch Processing Limitations

Most retort furnaces operate on a batch-by-batch basis. While ideal for high-value or varied parts, this can be less efficient for continuous, high-volume production of a single item compared to conveyor or tunnel furnaces.

Mechanical Complexity and Maintenance

The sealed nature of the retort introduces mechanical components like gaskets, seals, and clamps. These components are critical for maintaining atmospheric integrity but can be points of failure and require regular maintenance or replacement.

Higher Initial Capital Cost

The precision engineering, control systems, and specialized materials required for a retort furnace typically result in a higher upfront investment compared to simpler, non-sealed atmospheric furnaces.

Is a Retort Furnace Right for Your Application?

Choosing the right furnace technology depends entirely on your process requirements and primary goals.

- If your primary focus is maximum material purity and preventing oxidation: The sealed retort is non-negotiable and provides the highest level of atmospheric control.

- If your primary focus is performing specialized treatments like nitriding or hydrogen brazing: A retort furnace is essential for safely and effectively managing the required process gases.

- If your primary focus is reducing process gas costs: The low atmosphere usage of a sealed retort offers significant long-term savings compared to continuously purged furnaces.

- If your primary focus is high-volume, low-cost production of non-sensitive parts: You should evaluate if the throughput of a batch retort system meets your needs, or if a continuous atmospheric furnace is a more economical choice.

Ultimately, choosing a retort furnace is an investment in process control, repeatability, and the final quality of your product.

Summary Table:

| Advantage | Description |

|---|---|

| Sealed Environment | Isolates material from external elements for superior purity and control. |

| Atmosphere Control | Allows use of inert or reactive gases to prevent oxidation and contamination. |

| Temperature Precision | Ensures accurate, repeatable thermal cycles for consistent results. |

| Process Versatility | Supports treatments like carburizing, nitriding, sintering, annealing, and brazing. |

| Operational Efficiency | Reduces gas usage and costs in specialized applications. |

Ready to enhance your laboratory's capabilities with a custom retort furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need superior purity, precise atmosphere control, or tailored heat treatments, we can help you achieve optimal results. Contact us today to discuss how our solutions can benefit your specific applications!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the key advantages of an experimental box type atmosphere furnace? Achieve Precise Environmental Control for Advanced Materials

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance