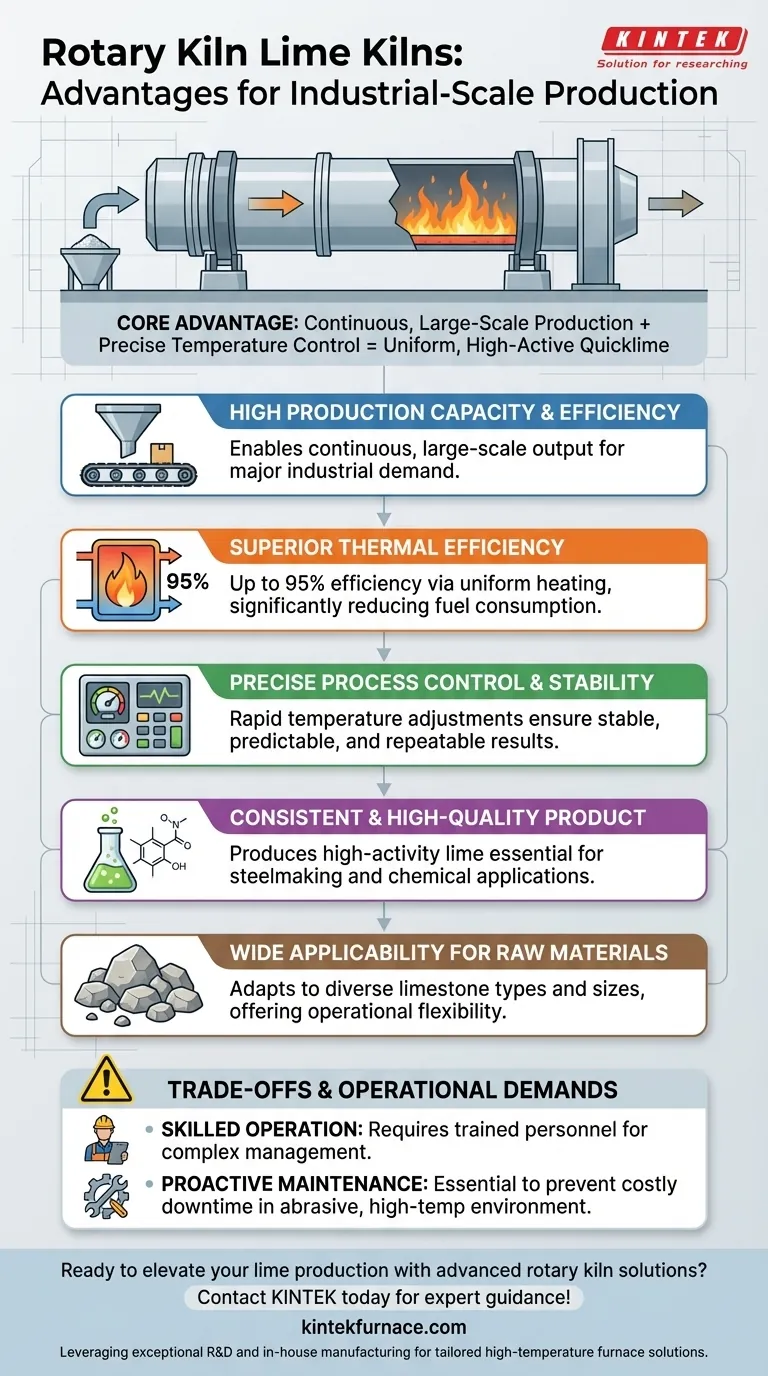

For industrial-scale lime production, rotary kilns offer a powerful combination of high capacity, superior thermal efficiency, and precise process control. These advantages result in a consistent, high-quality final product suitable for demanding applications in steelmaking, construction, and chemical manufacturing.

The core advantage of a rotary kiln is its ability to support continuous, large-scale production with exceptional control over temperature. This translates directly to a highly uniform and active quicklime, but it comes at the cost of higher operational complexity.

The Core Advantages of Rotary Kiln Technology

A rotary kiln calcines limestone into quicklime through a continuous, high-temperature process. Understanding the key benefits of this design is crucial for evaluating its suitability for your specific production goals.

High Production Capacity and Efficiency

Rotary kilns are designed for high-volume, continuous operation. Their ability to process large amounts of raw material in short cycles makes them the standard for major industrial applications.

This high throughput is a significant economic advantage for producers who need to meet substantial and consistent market demand.

Superior Thermal Efficiency

Modern rotary kilns achieve extremely high thermal efficiency, with some designs reaching up to 95%. The rotating motion of the kiln tumbles the material, ensuring uniform heat exposure.

This uniform heating minimizes energy waste and reduces fuel consumption per ton of product, making the operation more economical and environmentally sustainable compared to less advanced kiln types.

Precise Process Control and Stability

The design of a rotary kiln allows for very strong controllability over the calcination process. Operators can make rapid and precise temperature adjustments to meet narrow process requirements.

This level of control ensures the process remains stable, preventing under-burnt or over-burnt material and leading to predictable, repeatable outcomes.

Consistent and High-Quality Product

The direct result of precise temperature control and uniform heating is a stable, high-quality product. Rotary kilns consistently produce quicklime with high activity.

High-activity lime is essential for applications where reactivity and chemical purity are critical, such as in steel manufacturing flux or certain chemical synthesis processes.

Wide Applicability for Raw Materials

Rotary kilns demonstrate strong adaptability to a wide variety of limestone types and sizes. This flexibility is a key operational advantage, as it allows a plant to source raw materials from different quarries without compromising the production process.

Understanding the Trade-offs and Operational Demands

While the advantages are significant, a rotary kiln is a complex piece of industrial machinery that carries specific requirements and challenges.

The Requirement for Skilled Operation

The operational complexity of a rotary kiln is its primary trade-off. It requires skilled technical personnel to manage the process, perform regular inspections, and interpret control data.

Enterprises must invest in robust technical training and maintenance management programs to ensure safe, efficient operation and enhance equipment stability.

Maintenance and Potential for Downtime

Improper operation or delayed maintenance can lead to equipment failures and costly production accidents. The high-temperature, abrasive environment inside the kiln places significant stress on its components.

A proactive maintenance strategy is not optional; it is essential for achieving a long service life and minimizing unplanned downtime.

Making the Right Choice for Your Goal

Selecting a kiln technology is a strategic decision that must align with your production scale, quality targets, and operational capabilities.

- If your primary focus is large-scale, continuous output: The high capacity and efficiency of a rotary kiln make it the definitive choice for industrial production.

- If your primary focus is achieving the highest product quality and consistency: The precise process control of a rotary kiln ensures you can produce the stable, high-activity lime required for specialized applications.

- If your primary focus is minimizing operational complexity and initial investment: You may need to evaluate smaller or less complex kiln types, as a rotary kiln demands significant capital and specialized technical expertise.

Ultimately, choosing a rotary kiln is an investment in high-volume, high-quality production that requires a parallel commitment to operational excellence.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| High Production Capacity | Enables continuous, large-scale output for industrial demand |

| Superior Thermal Efficiency | Reduces fuel consumption with up to 95% efficiency, lowering costs |

| Precise Process Control | Ensures stable temperature adjustments for repeatable results |

| Consistent Product Quality | Produces high-activity lime ideal for steelmaking and chemicals |

| Wide Raw Material Applicability | Adapts to various limestone types and sizes for flexibility |

Ready to elevate your lime production with advanced rotary kiln solutions? Contact KINTEK today for expert guidance! Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse industries with tailored high-temperature furnace solutions. Our product line, including Rotary Furnaces, Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique production needs, ensuring enhanced efficiency, quality, and reliability for your operations.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control

- How does the heating process work in rotary tube furnaces? Achieve Uniform Heat for Powders and Granules

- How does a rotary tube furnace operate? Master Continuous Heating for Uniform Results

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries