Melting metals under a vacuum or protective atmosphere is a foundational technique for producing high-purity, high-performance materials. Its core advantages include the near-total prevention of oxidation, a significant reduction in dissolved gas content, the removal of volatile impurities, and superior control over the final alloy composition, all of which lead to a much higher quality casting.

The fundamental benefit is not just about avoiding contamination; it's about gaining absolute control. By removing the reactive atmosphere, you directly control the metal's purity and chemistry, which translates to predictable, superior mechanical properties in the final product.

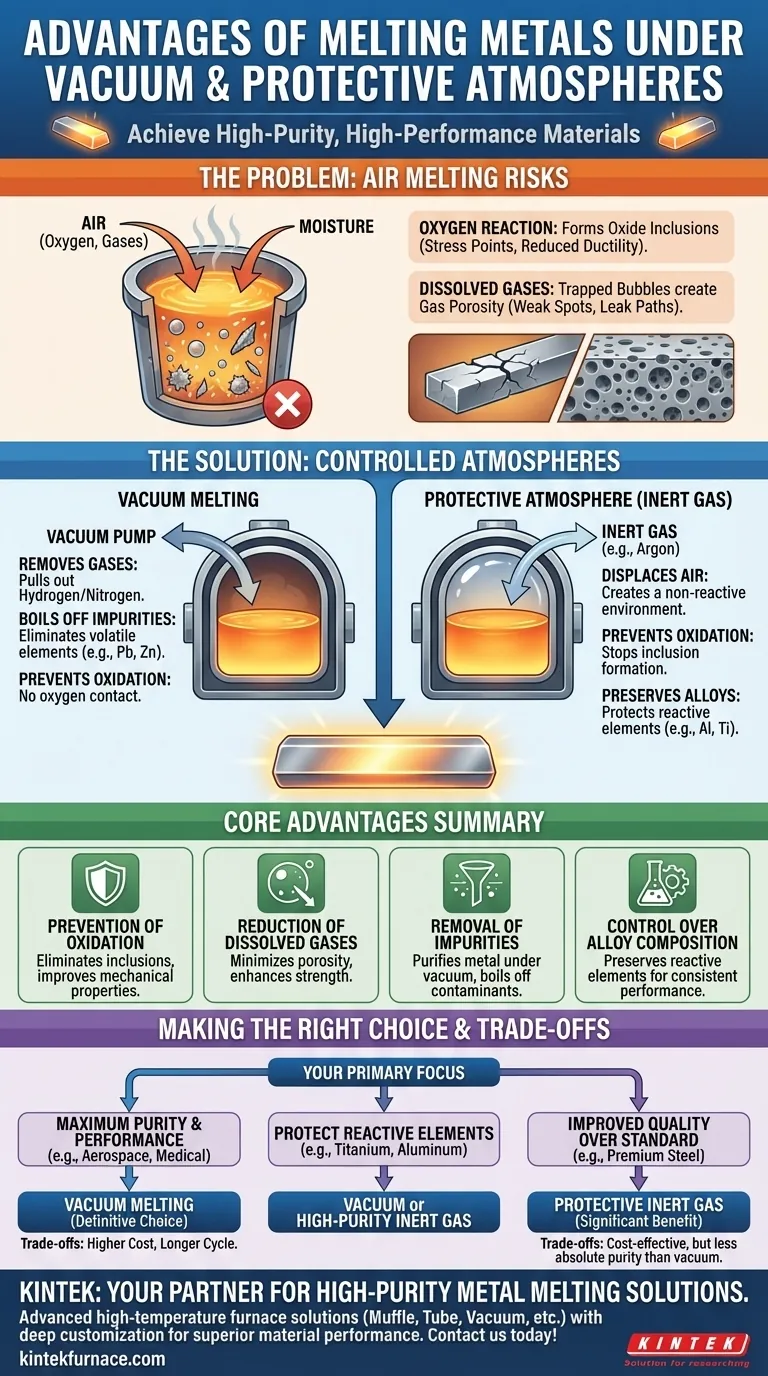

The Problem: Why Air is Hostile to Molten Metal

Melting metal in the open air introduces two primary contaminants: oxygen and dissolved gases. These contaminants are the root cause of many common material failures.

The Impact of Oxygen

Oxygen in the atmosphere aggressively reacts with molten metal, especially with highly reactive alloying elements like aluminum, titanium, and chromium. This reaction forms oxide inclusions, which are essentially tiny ceramic particles suspended in the metal.

These inclusions act as internal stress points, drastically reducing the material's ductility, fatigue life, and corrosion resistance. They also disrupt the intended microstructure of the alloy.

The Threat of Dissolved Gases

Gases like hydrogen and nitrogen, present in the air and moisture, readily dissolve into molten metal. As the metal cools and solidifies, the solubility of these gases drops sharply.

The gases are forced out of the solution, forming microscopic bubbles that get trapped in the solid metal. This results in gas porosity, a critical defect that creates weak spots and potential leak paths in a finished part.

How Controlled Atmospheres Deliver Purity and Performance

Using a vacuum or an inert protective atmosphere (like argon) directly counteracts the threats of atmospheric contamination. This provides precise control over the final material.

Preventing Oxidation and Inclusions

By removing oxygen from the environment, you prevent the formation of oxide inclusions. A vacuum physically removes the air, while a protective atmosphere displaces it with a non-reactive gas like argon.

This leads to a "cleaner" metal with vastly improved mechanical properties. The absence of inclusions is critical for components subjected to high stress or cyclical loading, such as turbine blades or medical implants.

Degassing and Removing Impurities

Placing molten metal under a vacuum does more than just prevent new contamination; it actively cleanses the metal. The low-pressure environment effectively "pulls" dissolved gases like hydrogen out of the liquid.

Furthermore, the combination of high heat and low pressure causes certain impurities with high vapor pressures (like lead, cadmium, or zinc) to boil off, further purifying the melt.

Preserving Precise Alloy Chemistry

Many advanced alloys depend on precise amounts of highly reactive elements to achieve their properties. In an air melt, these elements would be lost to oxidation, making the final chemistry unpredictable and inconsistent.

Melting under a vacuum or inert gas protects these expensive and critical alloying elements. This ensures the final product has the exact chemical composition and uniform structure intended by its designers.

Understanding the Trade-offs

While the benefits are significant, these processes are not a universal solution. The decision to use them involves clear trade-offs.

Cost and Complexity

Vacuum induction melting (VIM) furnaces and the associated equipment are significantly more expensive to purchase, operate, and maintain than standard air-melt furnaces. They require highly skilled operators and more complex process controls.

Process Limitations and Cycle Times

Achieving and maintaining a deep vacuum takes time, leading to longer overall cycle times compared to air melting. This can reduce throughput for high-volume production. Additionally, the vacuum can inadvertently remove beneficial volatile elements from certain alloys if not controlled properly.

Making the Right Choice for Your Application

The choice between air, protective atmosphere, or vacuum melting depends entirely on the required performance and cost constraints of your final product.

- If your primary focus is maximum purity and performance (e.g., aerospace superalloys, medical implants): Vacuum melting is the definitive choice and often a mandatory requirement.

- If your primary focus is protecting reactive elements (e.g., titanium or aluminum alloys): A vacuum or a high-purity inert gas atmosphere is essential to prevent the loss of critical alloy additions and ensure material properties.

- If your primary focus is improved quality over standard casting (e.g., premium steel or copper components): A protective inert gas atmosphere provides a significant benefit by reducing oxidation and porosity without the full cost of a vacuum system.

Ultimately, choosing the right melting environment is a foundational decision that dictates the ultimate capability and reliability of your material.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Prevention of Oxidation | Eliminates oxide inclusions for improved mechanical properties |

| Reduction of Dissolved Gases | Minimizes gas porosity to enhance strength and durability |

| Removal of Volatile Impurities | Purifies metal by boiling off contaminants under vacuum |

| Control over Alloy Composition | Preserves reactive elements for consistent, high-performance alloys |

Need high-purity metal melting solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental requirements for superior material performance. Contact us today to discuss how our tailored solutions can benefit your lab!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control