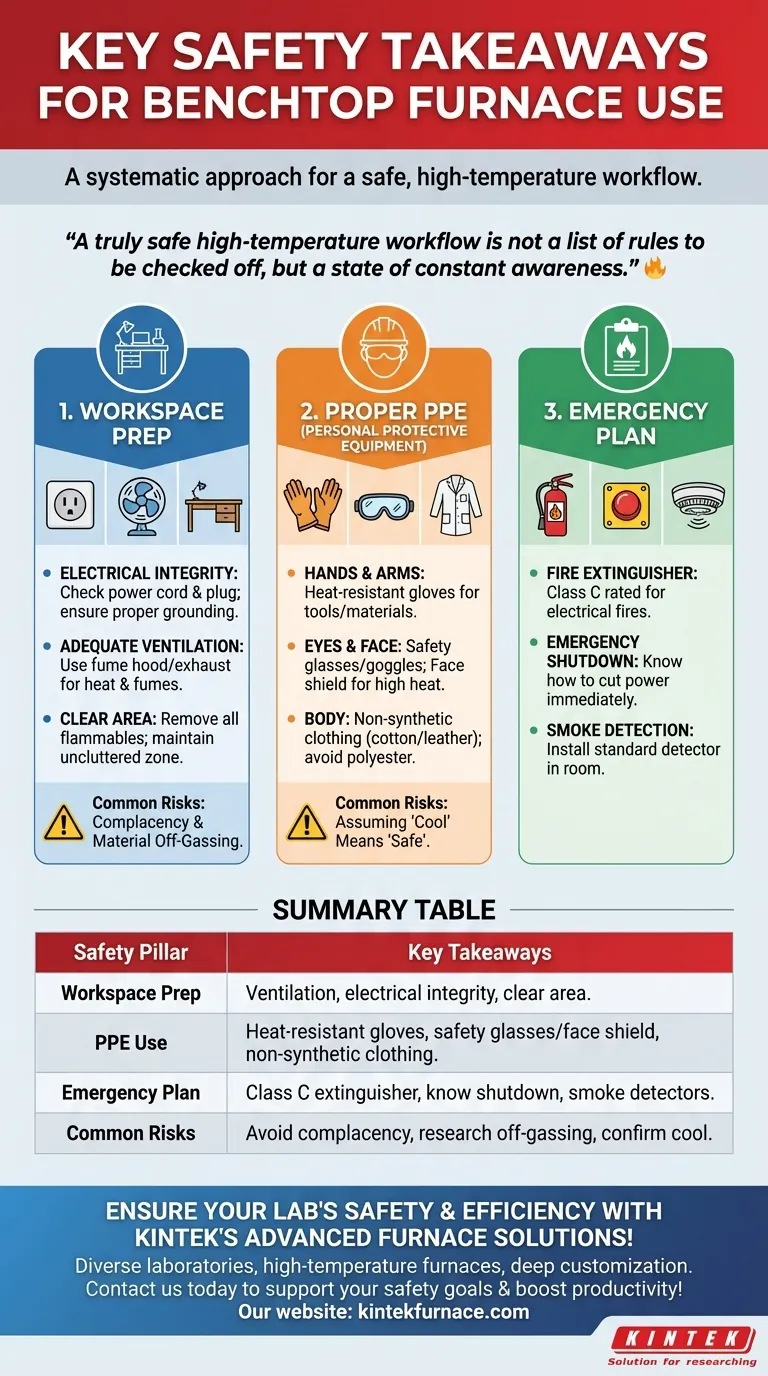

Operating a benchtop furnace requires a systematic approach to safety that extends beyond simply turning it on. The key safety takeaways involve three core pillars: preparing the workspace with proper ventilation and electrical checks, using the correct Personal Protective Equipment (PPE) for heat and debris, and establishing a clear emergency plan that includes a suitable fire extinguisher and knowledge of the shutdown procedure.

A truly safe high-temperature workflow is not a list of rules to be checked off, but a state of constant awareness. It begins with preparing the environment before the furnace heats up and ends only after the equipment and material have fully cooled.

Foundational Safety: Preparing Your Workspace

Before you even consider turning on the furnace, you must verify the integrity of the environment around it. This foundational step prevents the most common and dangerous incidents.

Prioritizing Electrical Integrity

The furnace is a high-draw electrical appliance, making its power source a primary point of failure. Always inspect the power cord for any signs of fraying, cracking, or damage to the plug.

Ensure the outlet is properly grounded to prevent electrical shock. If you have any doubt about the electrical setup, consult the user manual or a qualified electrician.

Ensuring Adequate Ventilation

Furnaces generate significant ambient heat and can release fumes from the materials being processed. Proper ventilation is non-negotiable to prevent heat buildup in the room and to exhaust potentially hazardous or toxic gases.

An active ventilation system, such as a fume hood or dedicated exhaust fan, is strongly recommended, especially when working with binders, coatings, or unknown materials.

Staging the Immediate Area

Maintain a clear, uncluttered zone around the furnace. Remove all flammable materials—including liquids, paper, and plastics—from the vicinity. A clean workspace not only reduces fire risk but also ensures you have a clear path in an emergency.

Personal Protective Equipment (PPE): Your First Line of Defense

PPE is your last and most personal barrier between you and a potential accident. Never operate a furnace without it.

Protecting Your Hands and Arms

Heat-resistant gloves are mandatory for handling any tools or materials that will go into or come out of the furnace. Ensure they are rated for the temperatures you are working with.

Shielding Your Eyes and Face

Safety glasses or goggles protect your eyes from projectiles or sparks. For operations involving opening the furnace door at high temperatures, a full face shield provides an essential extra layer of protection against intense radiant heat.

Covering Your Body

Wear non-synthetic clothing, like a cotton lab coat or leather apron, to protect against sparks and heat. Synthetic fabrics like polyester can melt and adhere to skin, causing severe burns.

Common Pitfalls and Overlooked Risks

Familiarity can lead to complacency. The most experienced users can fall victim to accidents by overlooking subtle but significant risks.

The Danger of Complacency

The most common cause of accidents is not equipment failure, but human error born from routine. Treat every operation with the same focus and respect for the heat and energy involved, even tasks you have performed a hundred times.

Ignoring Material Off-Gassing

Many materials release chemical fumes when heated. These can range from irritating to highly toxic. Always research the material you are heating and consult its Safety Data Sheet (SDS) to understand any potential off-gassing hazards.

Assuming 'Cool' Means 'Safe'

A furnace and its contents can remain dangerously hot long after the power has been turned off. Never touch any part of the unit or its contents without heat-resistant gloves unless you have confirmed it has returned to ambient temperature.

Emergency Preparedness: Your Action Plan

When an incident occurs, you will not have time to read a manual. A clear, rehearsed plan is your most critical safety tool.

The Correct Fire Extinguisher

Keep a fire extinguisher rated for electrical fires (Class C) within easy reach. A furnace fire starts as an electrical fire, and using the wrong type of extinguisher (like water) can make the situation catastrophically worse.

Knowing the Emergency Shutdown

You must know how to shut off power to the furnace immediately. This may involve a button on the unit, a specific breaker in your electrical panel, or an emergency stop button for the room. Identify and label this shutdown method before you begin work.

Smoke and Fume Detection

A standard smoke detector should be installed in the room as a baseline safety measure to alert you to any fire that might originate from a malfunction.

Making the Right Choice for Your Goal

Your specific application dictates which safety measures demand the most attention.

- If your primary focus is hobbyist work at home: Your priority is robust electrical safety and establishing a dedicated, cleared workspace away from all combustibles.

- If your primary focus is a professional lab or shared space: Your priority must be documented procedures and ensuring every potential user is trained on the emergency shutdown protocol.

- If your primary focus is material testing or R&D: Comprehensive ventilation and researching material off-gassing are your most critical safety concerns.

Ultimately, integrating safety into every step of your process is the only way to ensure a productive and secure outcome.

Summary Table:

| Safety Pillar | Key Takeaways |

|---|---|

| Workspace Prep | Ensure proper ventilation, electrical integrity, and clear area free of flammables. |

| PPE Use | Wear heat-resistant gloves, safety glasses/face shield, and non-synthetic clothing. |

| Emergency Plan | Have a Class C fire extinguisher, know shutdown procedures, and install smoke detectors. |

| Common Risks | Avoid complacency, research material off-gassing, and confirm equipment is cool before handling. |

Ensure your lab's safety and efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs, enhancing precision and reliability. Contact us today to discuss how our tailored solutions can support your safety goals and boost productivity!

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- How does vacuum heat treatment reduce workpiece deformation? Achieve Superior Dimensional Stability

- How are parts loaded into a vacuum furnace? Ensure Precision and Efficiency in Your Process