In essence, an effective heating element is defined by a precise balance of properties that allow it to reliably convert electricity into heat without degrading. The most critical properties are high electrical resistivity, a high melting point, strong resistance to oxidation at operating temperatures, mechanical durability, and a stable temperature coefficient of resistance. These ensure the element produces heat efficiently, maintains its shape, and has a long service life.

The selection of a heating element is not a search for a single "best" material, but a calculated trade-off. The optimal choice aligns the material's electrical, thermal, and mechanical properties with the specific temperature, environment, and performance demands of the application.

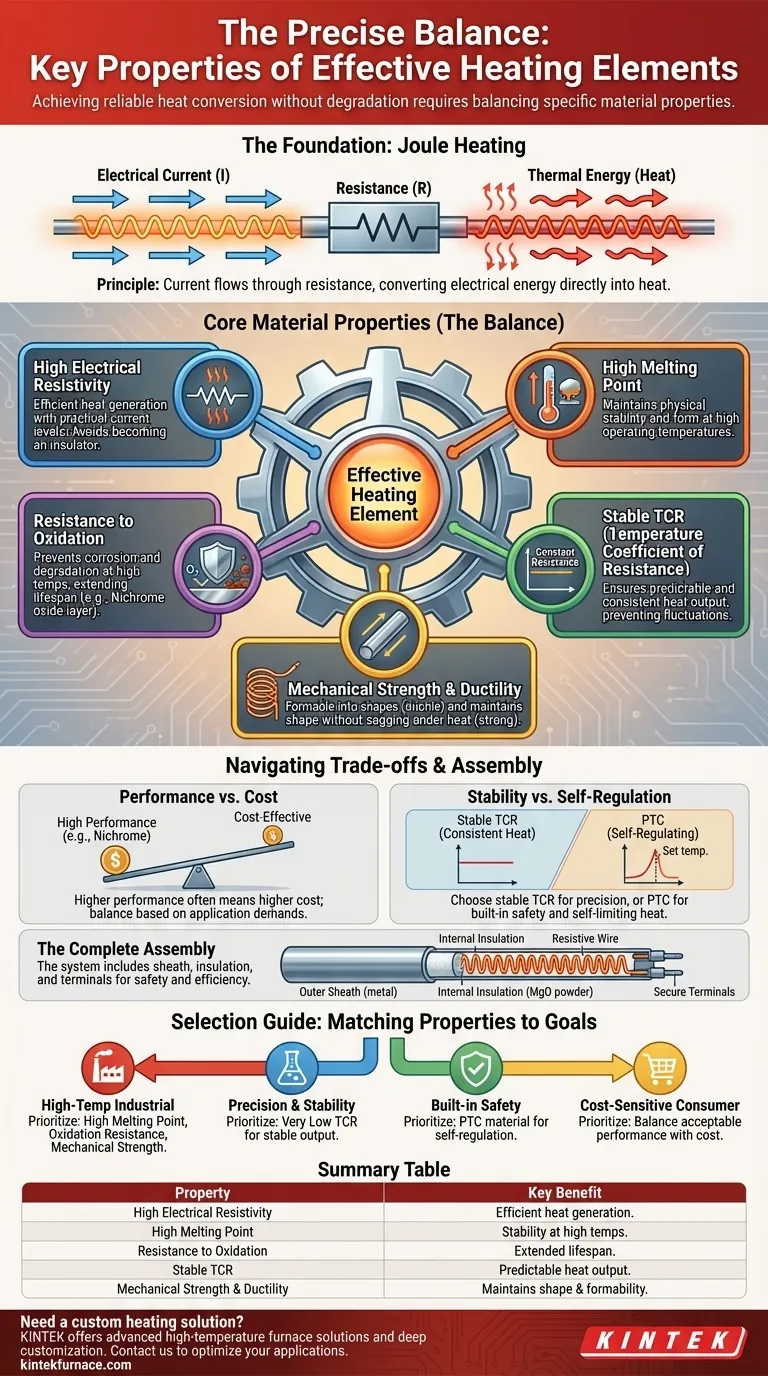

The Foundation: How Heating Elements Work

The Principle of Joule Heating

A heating element operates on a principle known as Joule heating. When an electrical current flows through a material, it encounters resistance.

This resistance impedes the flow of electrons, causing electrical energy to be converted directly into thermal energy, or heat. The effectiveness of this conversion is central to the element's function.

Core Properties of the Resistive Material

The heart of any heating element is its resistive wire or strip. Its material composition dictates its performance and suitability for a given task.

High Electrical Resistivity

The material must have high electrical resistance to generate substantial heat with a reasonable amount of current. However, if resistivity is too high, it becomes an insulator, preventing current from flowing at all.

The goal is a "Goldilocks" level of resistivity—high enough for efficient heat generation, but low enough to allow for practical voltage and current levels.

High Melting Point

A heating element must operate well below its melting point to remain physically stable. A high melting point is a prerequisite for any high-temperature application.

This property ensures the element can generate significant heat without changing its state, deforming, or failing.

Resistance to High-Temperature Oxidation

At elevated temperatures, most metals react with oxygen in the air, a process called oxidation. This corrosion causes the material to degrade, become brittle, and eventually fail.

Effective heating elements, like nickel-chromium (Nichrome) alloys, form a protective outer layer of oxide that prevents further oxidation, dramatically extending their operational lifespan.

Stable Temperature Coefficient of Resistance (TCR)

For most applications, it is crucial that the element's resistance remains relatively constant as its temperature changes. This is known as a low Temperature Coefficient of Resistance (TCR).

A low TCR ensures a stable and predictable heat output, preventing temperature fluctuations as the element cycles on and off.

Mechanical Strength and Ductility

A heating element must possess two key mechanical properties. First, it needs to be ductile enough to be drawn into wires and formed into coils or other shapes without breaking.

Second, it must have high mechanical strength at operating temperatures. This prevents it from sagging, stretching, or becoming brittle, ensuring it holds its intended shape throughout its life.

Understanding the Trade-offs

Choosing a heating element involves balancing competing priorities. An ideal material for one factor may be a poor choice for another.

Performance vs. Cost

High-performance materials that excel at high temperatures and resist oxidation, such as nickel-chromium alloys, are generally more expensive.

For less demanding consumer applications, a more cost-effective material may provide adequate performance, representing a common engineering trade-off.

Stability vs. Self-Regulation

While most applications require a stable TCR for consistent heat, some require the opposite. Polymer PTC (Positive Temperature Coefficient) materials are designed so their resistance increases dramatically at a specific temperature.

This feature allows for the design of self-regulating heaters that automatically reduce their heat output as they reach their target temperature, which is ideal for safety-critical, low-temperature applications.

The Complete Assembly

An effective heating element is more than just its resistive wire. It is a system where each component plays a role. The protective sheath, internal insulation (like magnesium oxide), and secure terminals are all critical to its overall safety, efficiency, and longevity.

Making the Right Choice for Your Application

Your final selection should be guided by your primary goal. Use the element’s intended function to prioritize its properties.

- If your primary focus is high-temperature industrial processes: Prioritize a high melting point, excellent oxidation resistance, and high mechanical strength.

- If your primary focus is precision and stable heat output: Prioritize a material with a very low Temperature Coefficient of Resistance (TCR).

- If your primary focus is built-in safety and over-temperature protection: Choose a PTC material that offers self-regulating properties.

- If your primary focus is a cost-sensitive consumer product: Balance acceptable performance on all fronts with the overall material and manufacturing cost.

Ultimately, selecting the right heating element is an engineering decision that aligns material science with the specific demands of the task at hand.

Summary Table:

| Property | Key Benefit |

|---|---|

| High Electrical Resistivity | Efficient heat generation with practical current levels |

| High Melting Point | Stability and durability at high temperatures |

| Resistance to Oxidation | Extended lifespan by preventing corrosion |

| Stable Temperature Coefficient of Resistance | Predictable and consistent heat output |

| Mechanical Strength and Ductility | Maintains shape and withstands forming processes |

Need a custom heating solution for your lab or industrial process? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements—enhancing efficiency, durability, and performance. Contact us today to discuss how we can optimize your heating applications!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure