When selecting a dental sintering furnace, the most critical features to evaluate are its temperature accuracy, the quality of its heating elements, and its chamber capacity. These factors directly determine the quality of your zirconia restorations, the furnace's lifespan, and its ability to meet your lab's production demands.

Choosing a sintering furnace is not just a technical decision; it's a strategic investment in the consistency and quality of your final dental restorations. The right furnace moves beyond simply heating materials to precisely controlling a complex metallurgical process.

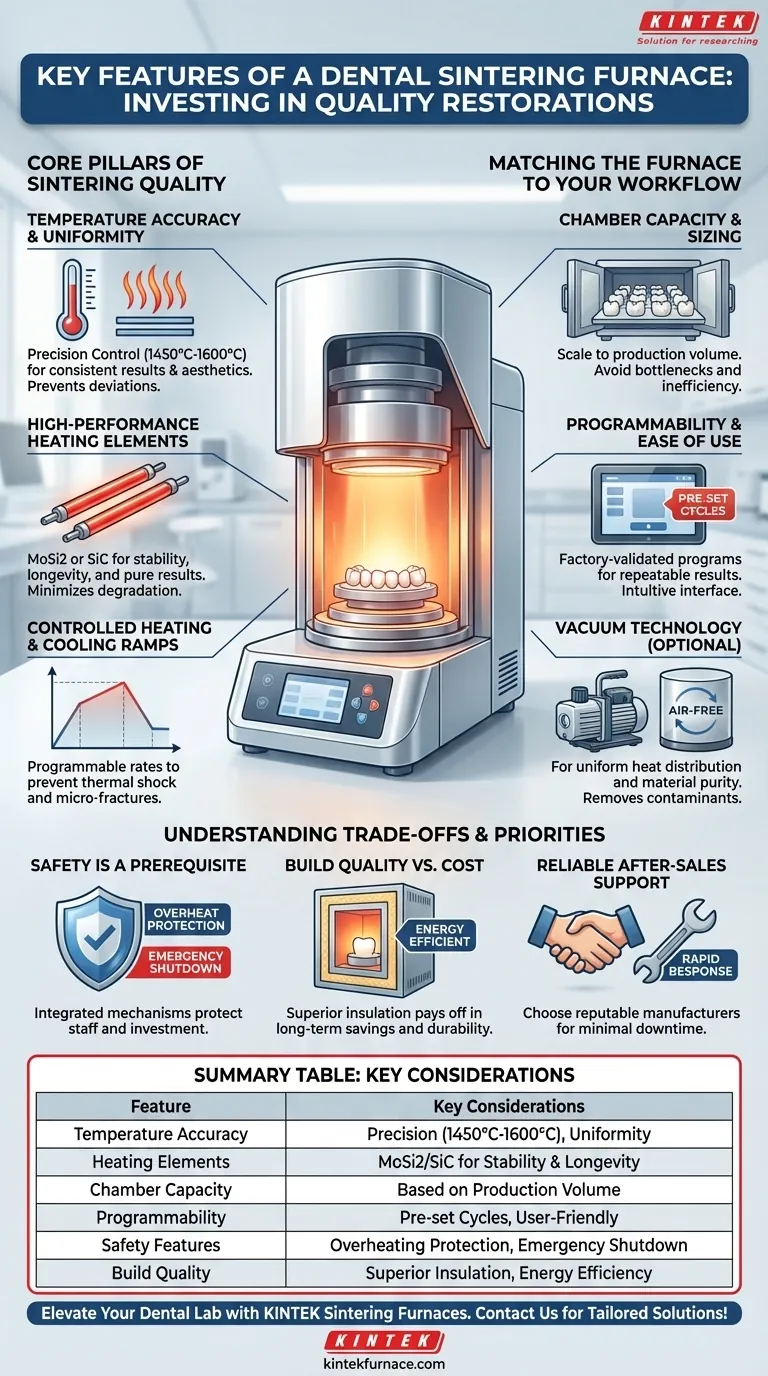

The Core Pillars of Sintering Quality

The final strength, fit, and aesthetic of a zirconia crown are not determined by the milling machine, but by the precision of the sintering cycle. The furnace is where the material's final properties are locked in.

Temperature Accuracy and Uniformity

A furnace's primary job is to achieve and hold a precise temperature. Zirconia requires a sintering temperature typically between 1450°C and 1600°C, and even minor deviations can compromise the restoration's translucency and strength.

Look for furnaces that guarantee temperature uniformity throughout the chamber. This ensures every restoration, regardless of its position on the tray, is sintered under identical conditions.

High-Performance Heating Elements

The heating elements are the engine of the furnace. Low-quality elements degrade quickly, leading to temperature fluctuations and costly replacements.

High-quality furnaces use either molybdenum disilicide (MoSi2) or silicon carbide (SiC) elements. These materials provide excellent temperature stability, a long service life, and are less likely to release contaminants that can discolor zirconia.

Controlled Heating and Cooling Ramps

The "ramp rate" refers to how quickly the furnace heats up and cools down. A rapid, uncontrolled cool-down can induce thermal shock, causing micro-fractures in the zirconia that lead to premature failure in the mouth.

A programmable furnace that allows you to control these ramp rates is essential for high-quality work, especially with high-translucency zirconia materials that are more sensitive to thermal stress.

Matching the Furnace to Your Workflow

Beyond the core technical specifications, a furnace must integrate seamlessly into your lab's daily operations. Practical features that support efficiency and reduce user error are just as important.

Sizing Your Chamber for Production Needs

Furnace capacity is a simple calculation. Analyze your average daily and weekly production of zirconia units to determine the chamber size you need.

Buying a furnace that is too small creates a production bottleneck. Conversely, consistently running a very large furnace for only a few units is inefficient. Plan for your current needs with an eye toward future growth.

Programmability and Ease of Use

Modern furnaces should come with pre-set, factory-validated programs for a variety of common zirconia materials. This removes guesswork and ensures consistent, repeatable results.

A clear, intuitive user interface reduces the learning curve for technicians and minimizes the risk of programming errors that could ruin an entire batch of restorations.

The Role of Vacuum Technology

Some advanced furnaces offer vacuum-assisted sintering. By removing air from the chamber during the cycle, a vacuum ensures perfectly uniform heat distribution and eliminates any atmospheric contaminants.

This feature is particularly valuable for achieving the highest level of material purity and is often used for sintering non-precious metal alloys.

Understanding the Trade-offs and Priorities

A higher price tag often corresponds to better components and more precise control, but it's crucial to understand where your money is going and what is truly essential for your goals.

Safety is Not a Feature, It's a Prerequisite

Any furnace you consider must have integrated safety mechanisms. These include automatic overheating protection and an emergency shutdown function.

Given the extremely high operating temperatures, these features protect your staff, your facility, and your investment. Do not consider any model that compromises on safety.

Build Quality vs. Initial Cost

A furnace's long-term value is tied to its build quality. Superior insulation, often made of high-purity ceramic fiberboard, means better heat retention, lower energy consumption, and a cooler external surface.

While a furnace with higher-quality heating elements and better insulation may have a higher initial cost, it will pay for itself over time through energy savings and reduced maintenance needs.

The Hidden Cost of Poor Support

A sintering furnace is a critical piece of equipment that cannot have significant downtime. Choosing a reputable manufacturer with reliable after-sales service and readily available parts is essential.

Before purchasing, investigate the manufacturer's reputation for customer support. A cheap furnace with no support can quickly become the most expensive piece of equipment in your lab.

Making the Right Choice for Your Lab

Your decision should be guided by your lab's specific priorities and production goals.

- If your primary focus is high-volume production: Prioritize a larger chamber capacity and a furnace known for reliable, repeatable cycles that require minimal supervision.

- If your primary focus is the highest aesthetic quality: Invest in a furnace with exceptionally precise temperature control, programmable cooling ramps, and high-purity MoSi2 elements.

- If your primary focus is a new or growing in-house lab: Emphasize ease of use with pre-programmed cycles for your chosen materials and select a manufacturer known for strong customer support.

Ultimately, selecting the right furnace is your final check on quality control, ensuring the restorations you produce are strong, beautiful, and built to last.

Summary Table:

| Feature | Key Considerations |

|---|---|

| Temperature Accuracy | Precision control (1450°C-1600°C), uniformity for consistent results |

| Heating Elements | High-quality materials like MoSi2 or SiC for stability and longevity |

| Chamber Capacity | Size based on production volume to avoid bottlenecks or inefficiency |

| Programmability | Pre-set cycles, user-friendly interface for repeatable outcomes |

| Safety Features | Overheating protection, emergency shutdown for lab safety |

| Build Quality | Superior insulation for energy efficiency and durability |

Elevate your dental lab's capabilities with KINTEK's advanced sintering furnaces. Leveraging exceptional R&D and in-house manufacturing, we provide tailored solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization ensures precise alignment with your unique experimental needs, delivering superior temperature control, reliability, and efficiency for high-quality zirconia restorations. Contact us today to discuss how we can support your production goals and enhance your lab's performance!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations