Choosing the right dental furnace requires looking beyond a simple feature list. The most critical factors are precise temperature control, programmability for different materials, and a chamber size that matches your workload. A reliable furnace must also have quality heating elements and, for porcelain work, effective vacuum technology.

The ideal furnace is not the one with the most features; it's the one that precisely and consistently processes your specific dental materials. Your decision should be driven by the requirements of the restorations you create, from high-strength zirconia to highly aesthetic porcelain veneers.

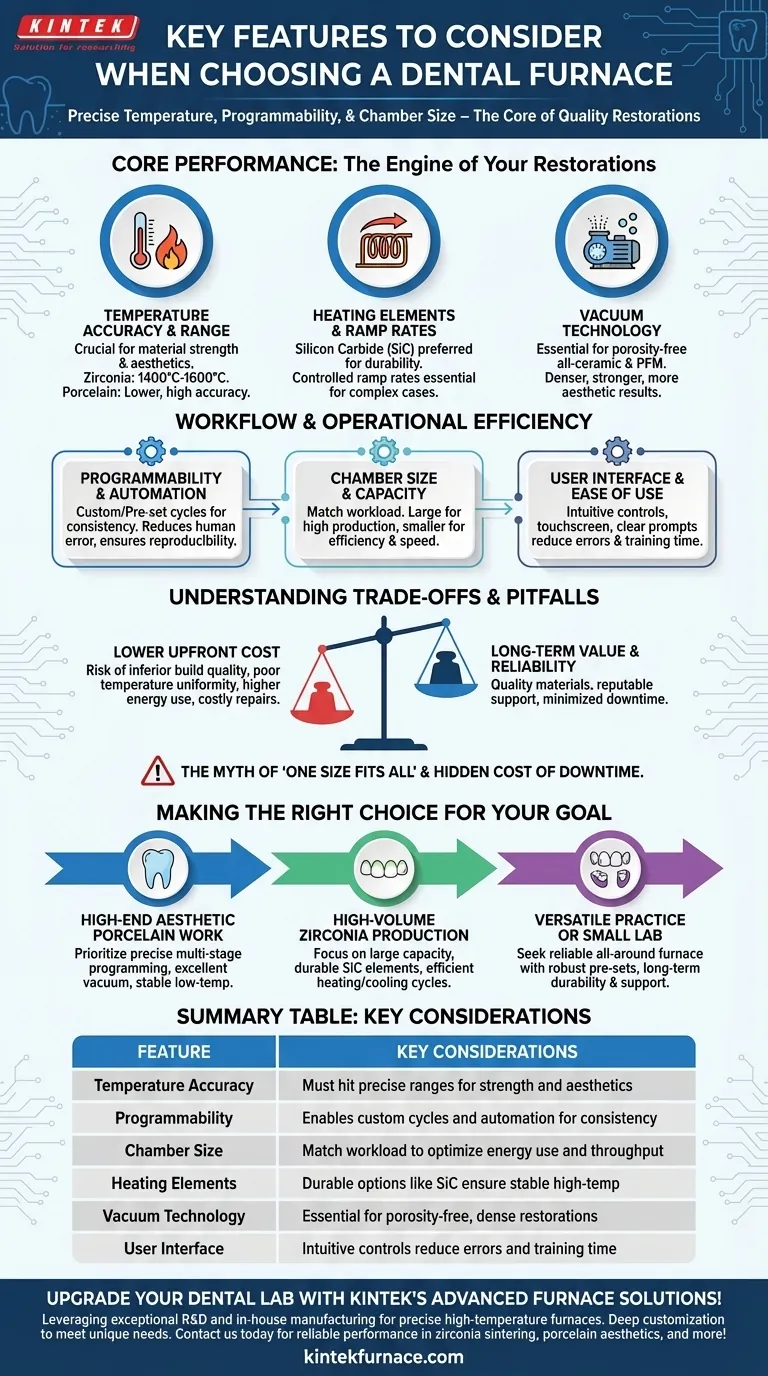

Core Performance: The Engine of Your Restorations

The fundamental purpose of a furnace is to transform materials through controlled heat. Its core performance characteristics directly dictate the quality, strength, and fit of the final restoration.

Temperature Accuracy and Range

A furnace's ability to hit and hold a precise temperature is non-negotiable. Different materials have vastly different firing and sintering requirements.

Modern zirconia, for example, often requires temperatures between 1400°C and 1600°C to achieve full strength and translucency. In contrast, many porcelains require lower temperatures but with even stricter accuracy to achieve the desired shade and vitality.

Heating Elements and Ramp Rates

The heating elements are the heart of the furnace. Silicon carbide (SiC) elements are often preferred for their durability and stability at high temperatures, especially for sintering zirconia.

The ramp rate—how quickly the furnace heats up and cools down—is also critical. Aggressive ramp rates can improve throughput but may introduce thermal stress into the restoration, while slow, controlled rates are essential for complex aesthetic porcelain cases.

Vacuum Technology

For all-ceramic and porcelain-fused-to-metal (PFM) restorations, a vacuum pump is essential. By removing air from the chamber during the firing cycle, it prevents bubbles and porosity.

This process results in a denser, stronger, and more aesthetic restoration with superior light-reflecting properties. The quality of the vacuum seal and pump directly impacts the final result.

Workflow and Operational Efficiency

A furnace that is difficult to use or doesn't match your workflow will create bottlenecks and introduce the potential for costly errors.

Programmability and Automation

The ability to save custom programs or use reliable pre-set cycles is a cornerstone of consistency. Automation reduces the chance of human error and ensures every unit is fired under the exact same conditions.

Look for a furnace that allows for both simple, pre-programmed cycles for common materials and the flexibility to create multi-stage custom programs for specialized cases.

Chamber Size and Capacity

The size of the firing chamber must align with your practice or lab's output. A large production lab needs a furnace that can handle many units simultaneously.

A smaller practice, however, might be better served by a smaller, more efficient furnace that can complete cycles faster without wasting energy heating an empty chamber.

User Interface and Ease of Use

A complicated interface increases the learning curve and the risk of inputting incorrect parameters. A modern furnace should have a clear, intuitive display and a logical menu structure.

Features like a touchscreen interface and clear on-screen prompts can significantly streamline daily operation and reduce training time for new staff.

Understanding the Trade-offs and Pitfalls

Investing in a dental furnace is a significant capital expenditure. Being aware of the common pitfalls ensures you are investing in long-term value, not just short-term savings.

The Myth of "One Size Fits All"

No single furnace excels at every task. A furnace optimized for high-temperature, long-cycle zirconia sintering may not be the most efficient or precise for low-fusing aesthetic porcelains. Be realistic about your primary material needs.

Build Quality vs. Initial Cost

A lower upfront cost can be tempting, but it often comes at the expense of build quality. Inferior insulation (like lower-grade ceramic fiberboard) or less durable heating elements can lead to poor temperature uniformity, higher energy consumption, and more frequent, costly repairs.

The Hidden Cost of Downtime

Every hour a furnace is out of service, your production stops. A reputable manufacturer with a strong track record for reliability and responsive customer support is a critical part of your investment. A cheaper unit from an unknown brand can become a major liability if you cannot get timely service or replacement parts.

Making the Right Choice for Your Goal

Select your furnace based on the primary type of work you perform. Aligning the technology with your clinical or business objective is the key to a successful investment.

- If your primary focus is high-end aesthetic porcelain work: Prioritize a furnace with precise, multi-stage programming, excellent vacuum control, and stable low-temperature performance.

- If your primary focus is high-volume zirconia production: Focus on a large-capacity furnace with durable silicon carbide heating elements and efficient, rapid heating and cooling cycles.

- If you are a versatile practice or small lab with a mixed workload: Seek a reliable all-around furnace with a robust library of pre-set programs and a reputation for long-term durability and support.

This deliberate approach ensures your furnace becomes a reliable asset that consistently produces high-quality restorations for your patients.

Summary Table:

| Feature | Key Considerations |

|---|---|

| Temperature Accuracy | Must hit precise ranges (e.g., 1400-1600°C for zirconia) for material strength and aesthetics |

| Programmability | Enables custom cycles and automation for consistency across different materials |

| Chamber Size | Should match workload to optimize energy use and throughput |

| Heating Elements | Durable options like silicon carbide ensure stable high-temperature performance |

| Vacuum Technology | Essential for porosity-free, dense restorations in porcelain and PFM work |

| User Interface | Intuitive controls reduce errors and training time for efficient operation |

Upgrade your dental lab with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precise high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, delivering reliable performance for zirconia sintering, porcelain aesthetics, and more. Contact us today to discuss how our tailored solutions can enhance your restoration quality and operational efficiency!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations