At its core, film uniformity in a Plasma-Enhanced Chemical Vapor Deposition (PECVD) system is achieved through equipment features that create an identical processing environment for every point on the substrate. The most critical features are a reactor design that enables uniform gas distribution across the wafer, precise and stable temperature control of the substrate holder, and a power delivery system that generates a consistent plasma density.

The goal of advanced PECVD equipment is not just to deposit a film, but to precisely manage the physics of the plasma and chemistry of the reaction. True uniformity comes from creating a perfectly stable and homogenous environment directly above the substrate surface.

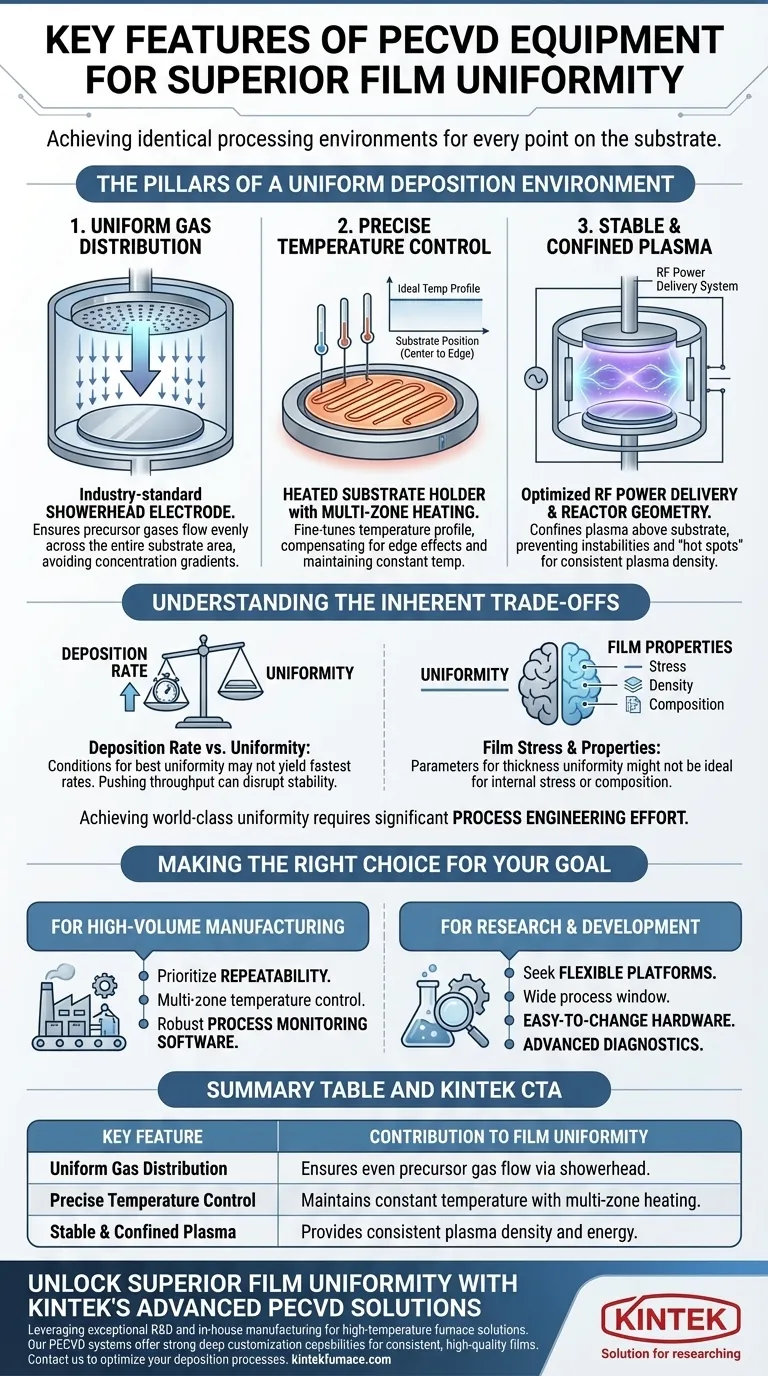

The Pillars of a Uniform Deposition Environment

Achieving a uniform film—whether in thickness, refractive index, or stoichiometry—requires that the flux and energy of reactive species arriving at the substrate surface are identical everywhere. Modern PECVD equipment is engineered specifically to control these factors.

1. Uniform Gas Distribution

The most fundamental feature for uniformity is the gas delivery system. Precursor gases must be introduced into the chamber in a way that avoids concentration gradients.

The industry-standard solution is the showerhead electrode. This is a large, plate-like electrode positioned directly above the substrate, perforated with thousands of precisely engineered holes.

This design forces the precursor gases to flow evenly across the entire substrate area, ensuring every point receives the same initial concentration of reactants.

2. Precise Temperature Control

Chemical reaction rates are highly sensitive to temperature. Even a small temperature variation across the substrate can lead to significant differences in film thickness and properties.

PECVD systems use a heated substrate holder, often called a chuck or a platen, with embedded heating elements and multiple temperature sensors.

Advanced systems feature multi-zone heating, allowing the controller to fine-tune the temperature profile and compensate for any edge effects or non-uniformities in plasma heating, ensuring the substrate remains at a constant temperature from center to edge.

3. Stable and Confined Plasma

The plasma is the engine of PECVD, breaking down stable precursor gases into highly reactive radicals. The density and energy of this plasma must be uniform.

This is achieved through the careful design of the RF power delivery system and the reactor geometry. The electrodes (often the showerhead and the substrate holder) are engineered to create a stable, capacitive discharge.

The chamber walls and pumping configuration are also designed to confine the plasma to the region directly above the substrate, preventing instabilities or "hot spots" that would disrupt uniformity.

Understanding the Inherent Trade-offs

Optimizing a PECVD system for uniformity is a balancing act. The features that promote uniformity can sometimes conflict with other process goals.

Deposition Rate vs. Uniformity

Often, the conditions that produce the most uniform films (e.g., lower pressure, specific gas flow ratios) do not produce the fastest deposition rates.

Pushing for higher throughput by increasing power or gas flows can introduce turbulence and disrupt the stable environment, degrading uniformity. A key part of process development is finding the optimal point between these two parameters.

Film Stress and Other Properties

The process parameters chosen for best thickness uniformity might not be ideal for other film properties, such as internal stress, density, or chemical composition.

For example, adjusting plasma power to improve uniformity can alter ion bombardment energy, which directly impacts the compressive or tensile stress of the resulting film.

The Complexity of Process Tuning

State-of-the-art equipment provides the tools for control, but it does not guarantee results out of the box. The interaction between gas flow, pressure, temperature, and plasma power is complex.

Achieving world-class uniformity requires significant process engineering effort to develop a recipe where all these parameters work in harmony for a specific film and substrate size.

Making the Right Choice for Your Goal

The ideal PECVD equipment depends entirely on your primary application. You must evaluate features based on the problems you need to solve.

- If your primary focus is high-volume manufacturing: Prioritize equipment with exceptional repeatability, multi-zone temperature control, and robust software for process monitoring to ensure wafer-to-wafer consistency.

- If your primary focus is research and development: Seek a flexible platform with a wide process window, easy-to-change hardware configurations, and advanced diagnostics to understand the underlying plasma physics.

Ultimately, superior film quality is a direct result of superior environmental control.

Summary Table:

| Key Feature | Contribution to Film Uniformity |

|---|---|

| Uniform Gas Distribution | Ensures even precursor gas flow across substrate via showerhead electrode |

| Precise Temperature Control | Maintains constant substrate temperature with multi-zone heating to prevent variations |

| Stable and Confined Plasma | Provides consistent plasma density and energy for uniform reactive species generation |

Unlock Superior Film Uniformity with KINTEK's Advanced PECVD Solutions

At KINTEK, we leverage exceptional R&D and in-house manufacturing to deliver high-temperature furnace solutions tailored for diverse laboratories. Our PECVD systems, part of a comprehensive product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, are designed with strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're in high-volume manufacturing or R&D, our equipment ensures precise environmental control for consistent, high-quality films.

Contact us today to discuss how we can optimize your deposition processes and achieve unparalleled results. Get in touch now!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- Is PECVD directional? Understanding Its Non-Line-of-Sight Advantage for Complex Coatings

- How does the PECVD process work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition