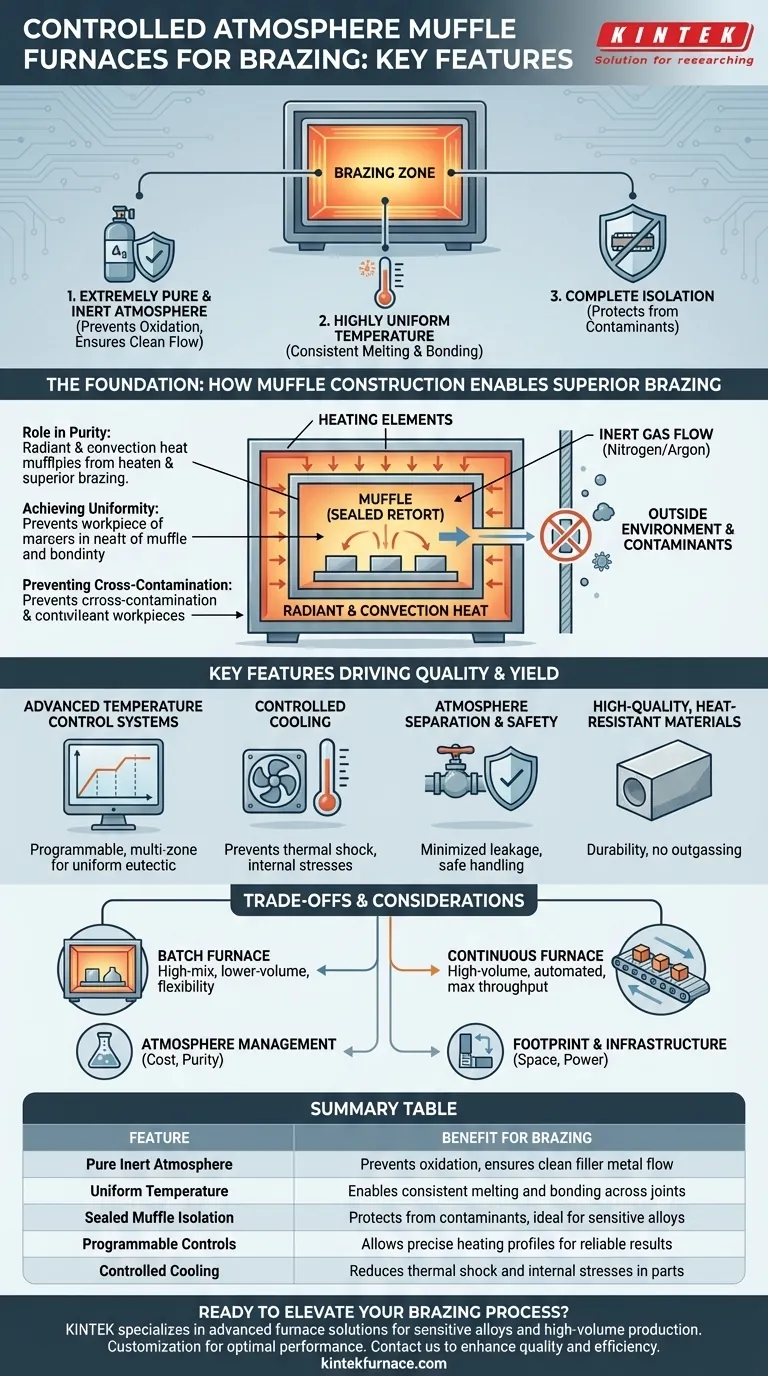

At their core, Controlled Atmosphere Muffle Furnaces are engineered to provide three critical capabilities for successful brazing: an extremely pure and inert atmosphere, highly uniform temperature, and complete isolation of the workpiece from external contaminants. These features work in concert to prevent oxidation and ensure the brazing filler metal can flow cleanly, creating strong, reliable, and repeatable joints.

The central challenge in brazing is not just applying heat, but controlling the environment in which that heat is applied. A controlled atmosphere muffle furnace solves this by creating a chemically stable, thermally uniform chamber, ensuring the integrity of both the base metals and the brazed joint itself.

The Foundation: How Muffle Construction Enables Superior Brazing

A "muffle" is the key architectural feature that defines this furnace type. It is essentially a sealed inner chamber or retort that separates the parts being processed from the heating elements and the outside environment.

The Role of the Muffle in Atmosphere Purity

The sealed muffle allows for the complete evacuation of ambient air and its replacement with a precisely controlled atmosphere. This is typically an inert gas, such as nitrogen or argon.

By creating this inert environment, the furnace prevents the formation of oxides on the metal surfaces during the high-temperature brazing cycle. This is critical for ensuring the filler metal can properly wet and bond with the parent materials.

Achieving Precise Temperature Uniformity

Muffle furnaces utilize a combination of radiant and convection heat transfer to ensure the entire workpiece reaches a homogeneous temperature. The heating elements heat the muffle, which then radiates heat evenly onto the parts inside.

This uniform heating is essential for consistent melting and flow of the brazing filler across the entire joint. It directly contributes to improved part uniformity and a higher process yield by eliminating hot or cold spots.

Preventing Cross-Contamination

The muffle acts as a physical barrier, isolating the high-purity interior from any potential contaminants. This prevents furnace insulation particles or other impurities from settling on the parts and interfering with the brazing process.

This isolation is especially vital when working with sensitive materials like superalloys or refractory metals, where even minor contamination can compromise the final product's metallurgical properties.

Key Features Driving Brazing Quality and Yield

Beyond the basic muffle design, several advanced features are optimized specifically for the demands of high-quality brazing.

Advanced Temperature Control Systems

Modern furnaces feature programmable, multi-zone controls. This allows operators to create precise heating profiles with specific ramps and soaks, ensuring the brazing filler material melts and solidifies at the exact right time and temperature.

This level of control is what allows for the creation of a uniform eutectic across the joint, leading to maximum strength and reliability.

Controlled Cooling of Heavy Loads

Just as important as heating is the cooling cycle. These furnaces offer controlled cooling rates, which are crucial for preventing thermal shock and internal stresses in the brazed assembly, particularly with heavy or complex parts.

Superior Atmosphere Separation and Safety

The design ensures excellent atmosphere separation, minimizing the leakage of the expensive inert gas and preventing air from entering the chamber.

These systems are also built with safe atmosphere compliance in mind, incorporating features to safely handle flammable atmospheres like hydrogen if used in the brazing process.

High-Quality, Heat-Resistant Materials

The muffle and other interior components are constructed from high-quality, heat-resistant materials like specialized ceramics or high-nickel alloys. This ensures durability, longevity, and prevents the furnace itself from outgassing and contaminating the process at high temperatures.

Understanding the Trade-offs and Considerations

While powerful, these furnaces are not a one-size-fits-all solution. Understanding their operational context is key to successful implementation.

Batch vs. Continuous Processing

Muffle furnaces come in two primary configurations. Batch furnaces are ideal for high-mix, lower-volume production or laboratory work due to their flexibility.

Continuous or "humpback" furnaces are designed for high-volume, automated production lines. They move parts through various temperature zones on a conveyor belt, offering maximum throughput and consistency for a specific product.

Atmosphere Management and Cost

Maintaining a high-purity atmosphere is an ongoing operational cost. The system requires a steady supply of inert gas, and its purity must be monitored, often using dew point sensors. Higher purity requirements translate to higher costs.

Footprint and Infrastructure

Even furnaces with "shorter footprints" are significant pieces of industrial equipment. They require dedicated floor space, substantial electrical power, and infrastructure for gas supply and cooling water.

Making the Right Choice for Your Brazing Application

Your final decision should be guided by the specific demands of your parts, materials, and production volume.

- If your primary focus is high-value, sensitive alloys: Prioritize a furnace with proven superior atmosphere purity (low dew point) and precise, programmable temperature controls.

- If your primary focus is high-volume production: A continuous muffle furnace with automated loading and pre-heating/cooling zones will deliver the best consistency and throughput.

- If your primary focus is process flexibility for varied parts: A batch-type muffle furnace offers the most versatility for different part sizes, materials, and heating profiles.

Ultimately, selecting the right furnace is about matching its environmental control capabilities to the metallurgical demands of your brazing process.

Summary Table:

| Feature | Benefit for Brazing |

|---|---|

| Pure Inert Atmosphere | Prevents oxidation, ensures clean filler metal flow |

| Uniform Temperature | Enables consistent melting and bonding across joints |

| Sealed Muffle Isolation | Protects from contaminants, ideal for sensitive alloys |

| Programmable Controls | Allows precise heating profiles for reliable results |

| Controlled Cooling | Reduces thermal shock and internal stresses in parts |

Ready to elevate your brazing process with precision and reliability? KINTEK specializes in advanced high-temperature furnace solutions, including Controlled Atmosphere Muffle Furnaces, designed to meet the unique needs of industries working with sensitive alloys and high-volume production. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to ensure optimal performance for your specific applications. Contact us today to discuss how our expertise can enhance your brazing quality and efficiency—Get in touch now!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality