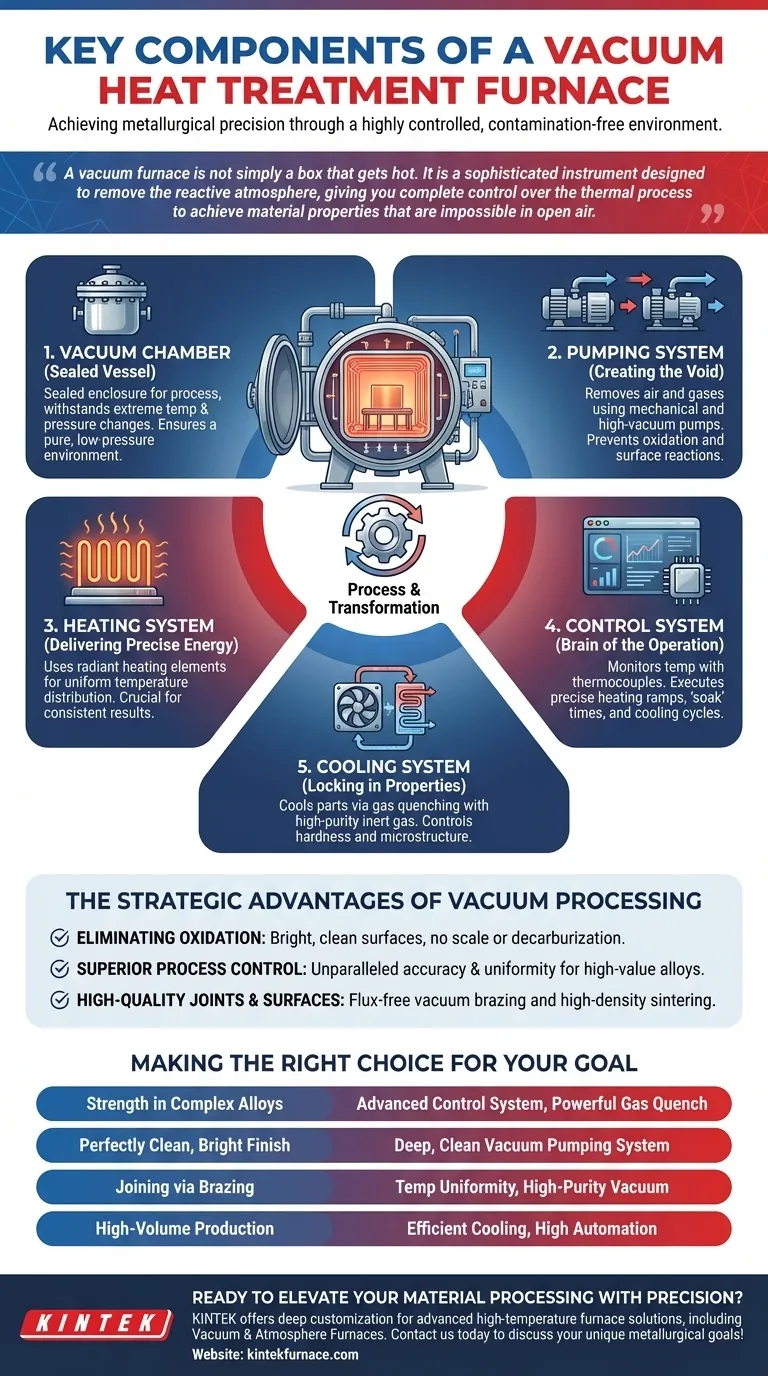

At the heart of any vacuum heat treatment furnace are five core systems working in concert to achieve metallurgical precision. The primary components are the vacuum chamber, the heating system, the temperature control system, the vacuum pumping system, and the cooling system. Together, they create a highly controlled, contamination-free environment for modifying the properties of metals and alloys.

A vacuum furnace is not simply a box that gets hot. It is a sophisticated instrument designed to remove the reactive atmosphere, giving you complete control over the thermal process to achieve material properties that are impossible in open air.

How the Core Components Create a Controlled Environment

The function of a vacuum furnace emerges from the seamless integration of its essential systems. Each component has a specific role in creating the vacuum, applying heat, and controlling the final properties of the workpiece.

The Vacuum Chamber: The Sealed Vessel

The vacuum chamber is the physical enclosure where the entire heat treatment process takes place. It is engineered to withstand extreme temperature changes and the immense external pressure when a deep vacuum is drawn inside. The integrity of this chamber is the first step in ensuring a pure, low-pressure environment.

The Pumping System: Creating the Void

This system is responsible for removing air and other gases from the chamber. It typically consists of a series of pumps, starting with a mechanical "roughing" pump to remove the bulk of the air, followed by a high-vacuum pump (like a diffusion or turbomolecular pump) to achieve the required low-pressure state. The quality of the vacuum is what prevents oxidation and other surface reactions.

The Heating System: Delivering Precise Energy

Inside the chamber, heating elements (often made of graphite or refractory metals like molybdenum) generate the required process heat. In a vacuum, heat is transferred primarily through radiation, which allows for extremely uniform temperature distribution across the workpiece. This uniformity is critical for consistent results and avoiding internal stresses.

The Control System: The Brain of the Operation

The temperature control system is the furnace's nerve center. It uses thermocouples to monitor the temperature of the workload and executes a pre-programmed cycle of heating ramps, "soak" times at specific temperatures, and controlled cooling. This high degree of electromechanical integration ensures that complex metallurgical processes like annealing, hardening, or brazing are perfectly repeatable.

The Cooling System: Locking in Material Properties

Once the heating cycle is complete, the part must be cooled at a specific rate to achieve the desired hardness and microstructure. The cooling system accomplishes this by backfilling the chamber with a high-purity inert gas (like nitrogen or argon) and circulating it with a powerful fan across a heat exchanger. This process is often called gas quenching.

The Strategic Advantages of Vacuum Processing

Understanding the components reveals why vacuum heat treatment is superior for many demanding applications. The benefits are a direct result of how the systems work together.

Eliminating Oxidation and Decarburization

The single greatest advantage is the complete elimination of surface reactions. By removing oxygen, the pumping system ensures parts emerge from the furnace with a bright, clean surface, free of scale or the loss of carbon (decarburization) that can plague conventional furnaces.

Achieving Superior Process Control

The combination of radiant heating and a sophisticated control system allows for unparalleled temperature accuracy and uniformity. This precision is essential for treating sensitive, high-value alloys used in industries like aerospace and medical, where material properties must meet exacting standards.

Ensuring High-Quality Joints and Surfaces

For processes like vacuum brazing, the clean environment allows filler metal to flow freely without the use of corrosive flux, resulting in stronger, cleaner joints. For sintering, the vacuum promotes the bonding of powder metal particles, leading to high-density components with minimal porosity.

Making the Right Choice for Your Goal

The capabilities of a vacuum furnace directly map to specific manufacturing outcomes. Your end goal should dictate which component capabilities you prioritize.

- If your primary focus is strength in complex alloys: Prioritize a furnace with an advanced control system for precise cycle execution and a powerful gas quench system for achieving specific hardness.

- If your primary focus is a perfectly clean, bright finish: Ensure the vacuum pumping system can achieve a deep, clean vacuum to prevent any possibility of surface oxidation.

- If your primary focus is joining dissimilar materials via brazing: The furnace's ability to maintain temperature uniformity and a high-purity vacuum is the most critical factor.

- If your primary focus is high-volume production: An efficient cooling system and a high degree of automation are key to minimizing cycle times and maximizing throughput.

By mastering the environment within the furnace, you gain ultimate control over the final properties of your material.

Summary Table:

| Component | Key Function |

|---|---|

| Vacuum Chamber | Sealed enclosure for process, withstands extreme conditions |

| Pumping System | Removes air and gases to create a low-pressure environment |

| Heating System | Uses radiation for uniform heat distribution |

| Control System | Monitors and executes precise temperature cycles |

| Cooling System | Cools parts via gas quenching to lock in properties |

Ready to elevate your material processing with precision? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for superior results in aerospace, medical, and other demanding industries. Contact us today to discuss how our tailored vacuum furnaces can enhance your lab's efficiency and achieve your specific metallurgical goals!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity