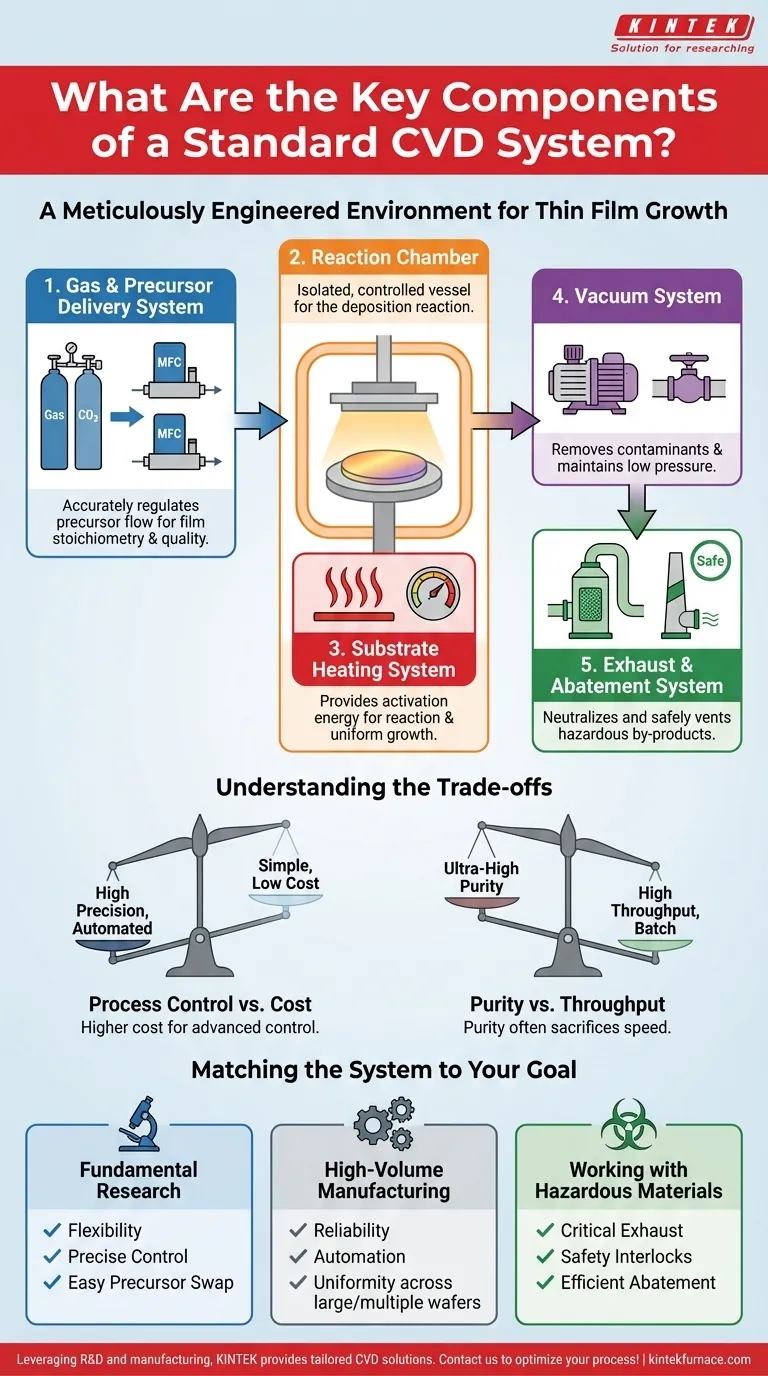

At its core, a standard Chemical Vapor Deposition (CVD) system is comprised of five key components. These are a gas delivery system, a reaction chamber, a substrate heating mechanism, a vacuum system, and an exhaust system. Each part performs a distinct function, working in concert to create a highly controlled environment for growing thin films on a substrate.

A CVD system is best understood not as a collection of parts, but as a meticulously engineered environment. Each component is a control lever for managing the flow of matter and energy, enabling the precise, layer-by-layer construction of new materials from gaseous precursors.

The Core Functional Blocks of a CVD System

To understand how a CVD system operates, it's helpful to follow the path of the precursor gases from their source to their final deposition and exhaustion. Each component plays a critical role in this journey.

The Gas & Precursor Delivery System

This is the starting point of the entire process. Its purpose is to supply the necessary chemical precursors—the building blocks of the film—to the reaction chamber in precise, repeatable amounts.

This system uses Mass Flow Controllers (MFCs) to accurately regulate the flow rate of each gas. This control is fundamental to determining the final stoichiometry and quality of the deposited film.

The Reaction Chamber

The reaction chamber is the heart of the CVD system. It is an enclosed vessel designed to contain the chemical reaction and isolate it from the outside atmosphere.

Chambers come in various designs, from simple horizontal tube furnaces for research to complex "showerhead" reactors for industrial production, but the core function is the same: to provide a stable stage for the deposition to occur.

The Substrate Heating System

Energy is required to break the chemical bonds of the precursor gases and initiate the deposition reaction on the substrate surface. The heating system provides this critical activation energy.

This can be achieved through various methods, such as resistive heating elements surrounding the chamber or lamps for rapid thermal processing. The ability to program and maintain a stable, uniform temperature is essential for consistent film growth.

The Vacuum System

The vacuum system serves two critical purposes. First, it removes ambient air and contaminants from the chamber before the process begins, ensuring a high-purity environment.

Second, it maintains the desired low pressure during deposition. By using pumps and throttle valves, the system controls the residence time of gases in the chamber and influences the mean free path of molecules, which directly impacts film properties like conformity.

The Exhaust & Abatement System

Once the gases have reacted or passed through the chamber, they must be safely removed. The exhaust system transports unreacted precursors and volatile by-products away from the chamber.

Because many CVD precursors and by-products are toxic, flammable, or corrosive, this stream is often fed into an abatement system (or "scrubber"). This final component neutralizes the hazardous materials before they are vented to the atmosphere.

Understanding the Trade-offs: Simplicity vs. Precision

No single CVD system design is perfect for every application. The choice and configuration of components involve fundamental trade-offs between cost, complexity, and performance.

Process Control vs. System Cost

A simple tube furnace with manual gas valves is inexpensive but offers limited control over film uniformity and repeatability. It may be suitable for basic material exploration.

In contrast, a production-grade system with automated MFCs, advanced chamber geometry, and in-situ monitoring provides exceptional precision. This precision comes at a significantly higher cost and operational complexity.

Purity vs. Throughput

Achieving ultra-high purity films requires a high-performance vacuum system (often using turbomolecular pumps) and meticulous contamination control, which can be slow and expensive.

For applications where throughput is more critical than absolute purity, a simpler vacuum system and a batch processing chamber might be used. This increases the number of substrates per run at the expense of the ultimate vacuum level.

Matching the System to Your Goal

The ideal configuration of a CVD system is defined entirely by its intended purpose. Understanding your primary objective is the first step in evaluating or designing a system.

- If your primary focus is fundamental research: Prioritize a system with maximum flexibility, precise programmable controls for temperature and pressure, and the ability to easily swap different precursors.

- If your primary focus is high-volume manufacturing: Emphasize reliability, automation, and chamber designs that maximize film uniformity across large substrates or multiple wafers at once.

- If your primary focus is working with hazardous materials: The design of the exhaust, safety interlocks, and abatement system becomes the most critical factor, outweighing almost all other considerations.

Ultimately, mastering CVD begins with recognizing that each component is a lever you can use to influence the final properties of your material.

Summary Table:

| Component | Key Function |

|---|---|

| Gas Delivery System | Supplies and regulates precursor gases for film stoichiometry |

| Reaction Chamber | Contains and isolates the chemical reaction for deposition |

| Substrate Heating System | Provides activation energy for uniform film growth |

| Vacuum System | Removes contaminants and controls pressure for film quality |

| Exhaust System | Safely removes and neutralizes hazardous by-products |

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're focused on research, manufacturing, or handling hazardous materials, our tailored CVD systems can enhance your precision, reliability, and safety. Contact us today to discuss how we can optimize your thin film deposition processes!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- How is silicon dioxide (SiO2) used in PECVD applications? Key Roles in Microfabrication

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition