At its core, a Chemical Vapor Deposition (CVD) furnace is a highly sophisticated reaction chamber designed for a single purpose: creating high-performance, solid thin films from gaseous precursors. Its defining characteristics are not just high heat, but an integrated system of extreme environmental controls. This includes precise temperature management, a tightly regulated atmosphere or vacuum, and the controlled introduction of reactive gases to deposit material atom-by-atom onto a substrate.

A CVD furnace should not be viewed as merely a high-temperature oven. Its true value lies in its ability to precisely orchestrate a chemical reaction at a molecular level, enabling the synthesis of exceptionally pure materials and uniform coatings that are impossible to create with other methods.

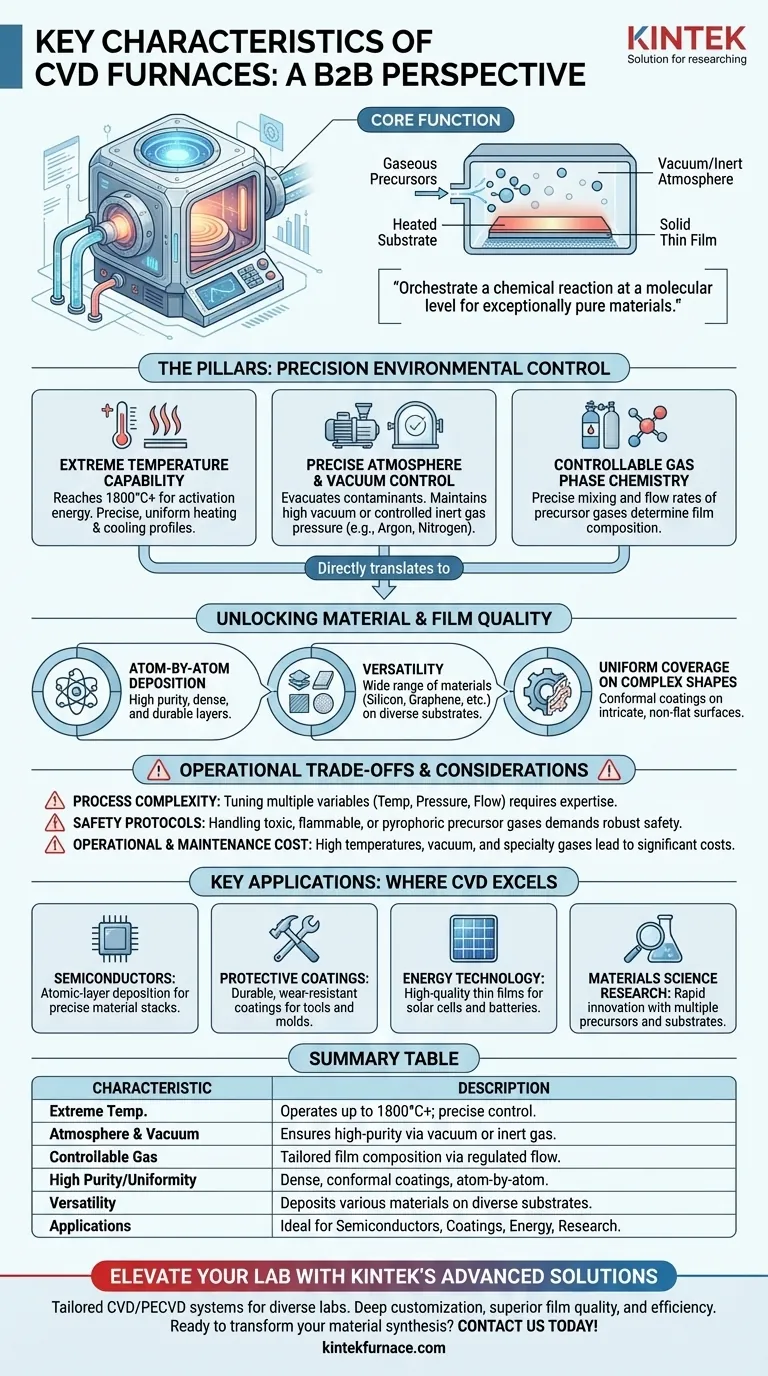

The Pillars of CVD: Precision Environmental Control

The effectiveness of any CVD process hinges on the furnace's ability to create and maintain a highly stable and predictable environment. This control is the foundation upon which film quality and reproducibility are built.

Extreme Temperature Capability

CVD furnaces are engineered to operate at very high temperatures, often reaching 1800°C or higher. This heat provides the necessary activation energy for the chemical reactions to occur on the substrate surface.

Crucially, this is paired with precise temperature control and uniform heating distribution. Advanced systems use programmable profiles to ensure the substrate is heated and cooled at an exact rate, which is vital for managing film stress and achieving the desired crystalline structure.

Precise Atmosphere and Vacuum Control

CVD is fundamentally a vacuum deposition method. The process chamber is first evacuated to remove contaminants like oxygen and water vapor, which would otherwise interfere with the reaction.

The system then maintains this vacuum or introduces specific inert gases (like argon or nitrogen) at a controlled low pressure. This control over the atmosphere is non-negotiable for depositing pure, high-quality films.

Controllable Gas Phase Chemistry

The furnace incorporates a sophisticated gas delivery system. This allows for the precise mixing and introduction of one or more precursor gases into the chamber.

By controlling the flow rates and composition of these gases, an operator has direct command over the chemistry of the deposition process, determining the final composition and properties of the deposited film.

Unlocking Material & Film Quality

The precise environmental controls directly translate into the ability to create materials with superior characteristics and apply them in versatile ways.

Atom-by-Atom Deposition for High Purity

Because the process builds films molecule by molecule, the resulting layers are exceptionally dense, pure, and durable. This atomic-level control is what distinguishes CVD and makes it essential for high-performance applications like semiconductor manufacturing.

Versatility in Materials and Substrates

A single CVD system can often be used to deposit a wide range of materials, including silicon, silicon nitride, graphene, and various hard coatings. This is achieved simply by changing the precursor gases.

Furthermore, the gaseous nature of the process allows it to be used on substrates of nearly any material that can withstand the process temperatures.

Uniform Coverage on Complex Shapes

Unlike line-of-sight deposition methods, the precursor gases in a CVD process can flow around and into complex, three-dimensional shapes. This results in a highly conformal and uniform coating, even on intricate or non-flat surfaces.

Understanding the Operational Trade-offs

While powerful, CVD technology comes with inherent complexities and considerations that must be managed for successful operation.

Process Complexity and Parameter Tuning

The number of variables—temperature, pressure, gas flow rates, and timing—creates a complex process window. Achieving optimized results requires expertise and careful, systematic experimentation to fine-tune the parameters for each specific application.

Precursor and Gas Handling Safety

Many precursor gases used in CVD are toxic, flammable, or pyrophoric (igniting spontaneously in air). Safe and reliable operation demands robust safety protocols, leak detection systems, and proper handling procedures.

Cost of Operation and Maintenance

The high temperatures, vacuum systems, and use of purified specialty gases contribute to significant operational costs. The complexity of the equipment also necessitates a rigorous preventative maintenance schedule to ensure reliability and uptime.

Key Applications: Where CVD Excels

The unique characteristics of CVD furnaces make them indispensable in several high-tech industries.

- If your primary focus is cutting-edge semiconductor fabrication: The precise control over atomic-layer deposition of materials like silicon is the most critical feature.

- If your primary focus is developing durable protective coatings: The furnace's ability to uniformly coat complex tools and molds with hard, wear-resistant materials is its key advantage.

- If your primary focus is energy technology: The capability to produce high-quality thin-film solar cells or components for next-generation batteries relies on CVD's material purity and deposition control.

- If your primary focus is materials science research: The flexibility to use multiple precursor gases and substrates allows for rapid innovation and the discovery of novel materials.

Understanding these core characteristics empowers you to leverage CVD technology not just as a tool, but as a gateway to advanced material creation.

Summary Table:

| Characteristic | Description |

|---|---|

| Extreme Temperature Capability | Operates up to 1800°C+ with precise control for uniform heating and cooling. |

| Precise Atmosphere and Vacuum Control | Maintains vacuum or inert gases to ensure high-purity film deposition. |

| Controllable Gas Phase Chemistry | Uses precursor gases with regulated flow for tailored film composition. |

| High Purity and Uniformity | Enables atom-by-atom deposition for dense, conformal coatings on complex shapes. |

| Versatility | Deposits various materials (e.g., silicon, graphene) on diverse substrates. |

| Applications | Ideal for semiconductors, protective coatings, energy tech, and materials research. |

Elevate your laboratory's capabilities with KINTEK's advanced CVD furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces, including CVD/PECVD Systems, tailored for diverse labs. Our deep customization ensures precise alignment with your unique experimental needs, delivering superior thin film quality and efficiency. Ready to transform your material synthesis? Contact us today to discuss how our expertise can drive your innovations forward!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment