At its core, a modern porcelain furnace is the critical instrument that allows a dental laboratory to transform raw ceramic materials into durable, lifelike, and perfectly fitting dental restorations. Its primary advantages are the ability to achieve superior aesthetic results that mimic natural teeth, engineer restorations with high clinical durability through precise heat treatment, and streamline laboratory workflow with efficient, repeatable processes.

A porcelain furnace is not merely an oven; it is a precision tool that grants the technician ultimate control over the final physical and aesthetic properties of a ceramic restoration. This control is the deciding factor in achieving clinical success, operational efficiency, and patient satisfaction.

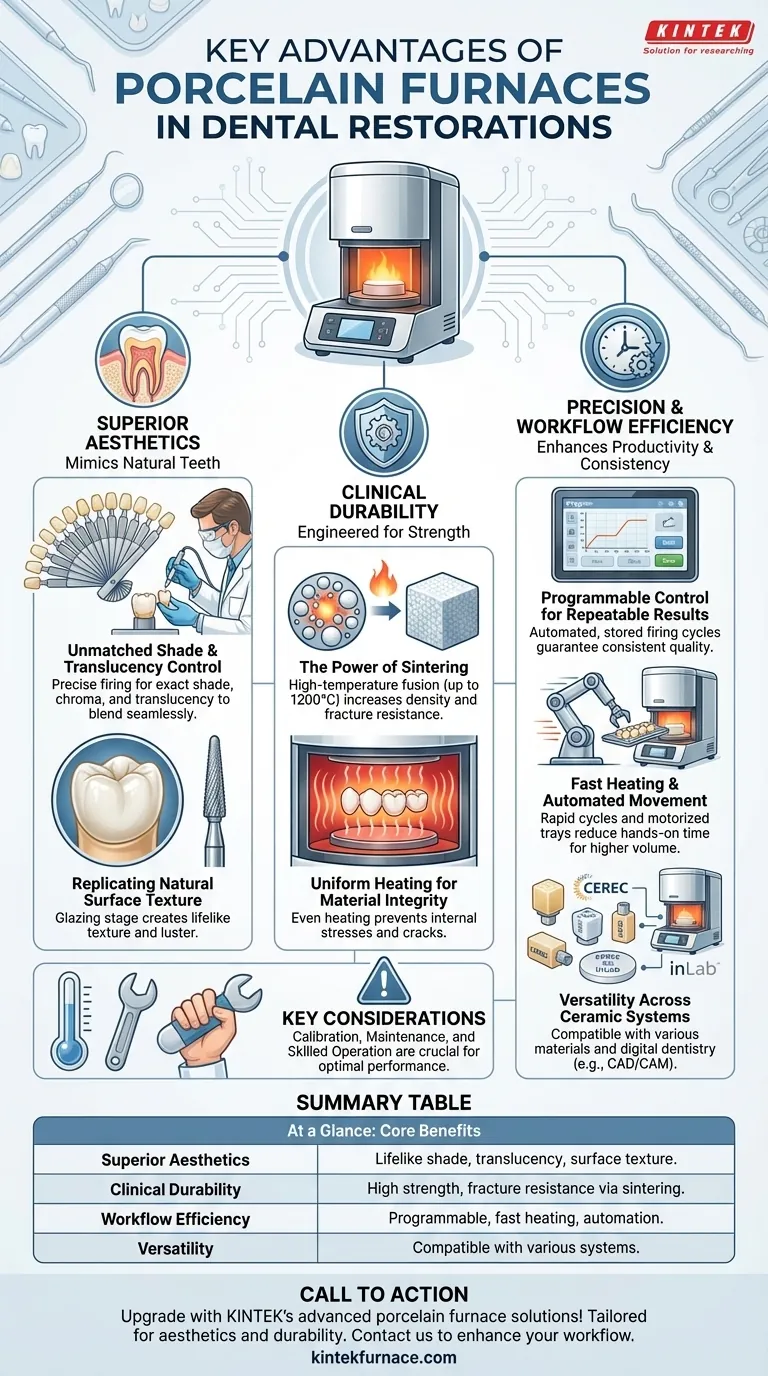

The Foundation of Superior Aesthetics

The most visible advantage of a quality porcelain furnace is its ability to produce restorations that are virtually indistinguishable from natural teeth. This is achieved through precise control over the firing process.

Unmatched Shade and Translucency Control

A furnace enables the technician to execute complex, multi-stage firing programs. This precision is essential for developing the exact shade, chroma, and translucency required to match a patient's adjacent teeth, ensuring the restoration blends seamlessly.

Replicating Natural Surface Texture

The final firing cycles, particularly the glazing stage, are managed by the furnace to create a final surface that replicates the texture and luster of natural tooth enamel. This is a critical detail for achieving a truly lifelike result.

Engineering for Clinical Durability

Aesthetics are meaningless if the restoration fails under the functional stresses of the oral environment. The furnace is directly responsible for imparting the necessary strength to the ceramic material.

The Power of Sintering

The primary function of the furnace is sintering—a process of heating ceramic particles to a high temperature (up to 1200°C or more) without melting them. This causes the particles to fuse together, eliminating pores and dramatically increasing the material's density, flexural strength, and fracture resistance.

Uniform Heating for Material Integrity

Modern furnaces are designed with uniform heating zones and highly reliable automatic process control. This ensures that the entire restoration is heated evenly, preventing internal stresses or weak spots that could lead to cracks and premature failure in the mouth.

Achieving Precision and Workflow Efficiency

Beyond the quality of the final product, porcelain furnaces bring significant operational benefits to the dental lab, enhancing productivity and consistency.

Programmable Control for Repeatable Results

With multi-segment programmable controllers and touch-screen displays, technicians can create, store, and execute precise firing cycles for different ceramic materials. This automation guarantees consistent, repeatable results for every case, reducing errors and remakes.

Fast Heating and Automated Movement

Features like rapid heating rates and motorized trays for automatic loading and unloading reduce hands-on time and shorten the overall processing duration. This allows a laboratory to handle a higher volume of work without compromising quality.

Versatility Across Ceramic Systems

Today's furnaces are not limited to one type of material. They are designed to cover a wide range of indications and are often built to complement specific digital dentistry product ranges, such as CEREC or inLab, providing versatility for labs that work with various ceramic systems.

Understanding the Key Considerations

While the advantages are clear, a furnace's performance is dependent on its proper use and maintenance.

The Critical Role of Calibration

A furnace is only as accurate as its temperature. Regular calibration is non-negotiable. An uncalibrated furnace that runs too hot or too cool will ruin restorations, wasting significant time and material.

Maintenance and Consumables

Reliability depends on upkeep. Components like the vacuum pump and heating muffle have a finite lifespan and require periodic maintenance or replacement. Accessories like sintering trays and tweezers are also part of the ongoing operational cost.

The Human Factor

While modern furnaces are easy to operate for standard programs, achieving the highest level of aesthetic customization still requires a skilled technician. The furnace is a tool, and its ultimate potential is unlocked by the artist who operates it.

Making the Right Choice for Your Goal

Selecting a furnace should be based on the specific needs and priorities of your laboratory.

- If your primary focus is high-end aesthetic restorations: Prioritize a furnace with advanced programmable controls and superior vacuum systems to manipulate translucency and characterization.

- If your primary focus is high-volume production: Look for models with fast heating/cooling cycles, robust automation features, and a reputation for reliability to maximize throughput.

- If your primary focus is versatility and digital integration: Select a furnace proven to work with a wide range of ceramic materials and that explicitly complements your existing CAD/CAM systems.

Ultimately, investing in the right porcelain furnace is a direct investment in your ability to deliver predictable, high-quality outcomes for your clients and their patients.

Summary Table:

| Advantage | Description |

|---|---|

| Superior Aesthetics | Achieves lifelike shade, translucency, and surface texture for natural-looking teeth. |

| Clinical Durability | Provides high strength and fracture resistance through precise sintering and uniform heating. |

| Workflow Efficiency | Offers programmable control, fast heating, and automation for consistent, high-volume results. |

| Versatility | Compatible with various ceramic systems and digital dentistry tools like CEREC and inLab. |

Upgrade your dental lab with KINTEK's advanced porcelain furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide dental laboratories with high-temperature furnaces tailored for superior aesthetics and durability. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique restoration needs. Contact us today to enhance your workflow and deliver predictable, high-quality outcomes for your clients!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations