In the field of thermal processing, rotary furnaces offer a unique combination of benefits that set them apart from static alternatives. Their primary advantages are exceptionally uniform heating, high energy efficiency, precise process control, and the versatility to handle continuous workflows with a wide variety of materials. This is achieved by combining indirect heating with the constant, gentle tumbling of the material within a rotating tube.

The defining feature of a rotary furnace is its ability to transform heating from a static event into a dynamic process. This rotation ensures every particle of the material receives identical thermal treatment, resulting in unparalleled product uniformity and process efficiency.

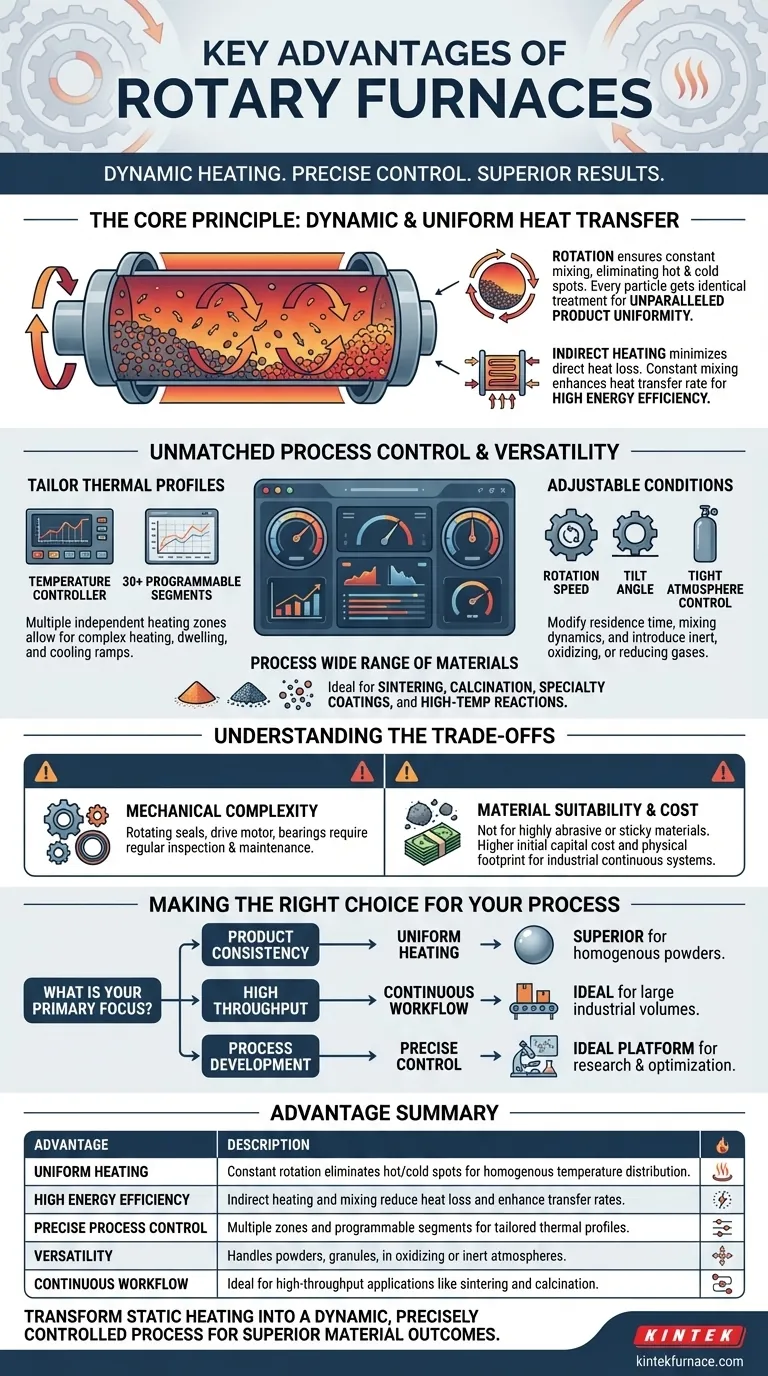

The Core Principle: Dynamic and Uniform Heat Transfer

The fundamental value of a rotary furnace comes from its constant motion. Unlike a static box furnace where material sits idle, a rotary furnace actively manipulates the material to achieve superior results.

How Rotation Guarantees Uniformity

The slow rotation of the furnace tube causes the material inside to gently tumble. This continuous mixing action eliminates hot and cold spots that can plague static systems.

Every particle is repeatedly brought to the heated inner surface of the tube and then folded back into the bulk of the material, ensuring a homogenous temperature distribution throughout the entire batch.

Achieving High Thermal Efficiency

Rotary furnaces typically use indirect heating, where external heating elements heat the outside of the processing tube. The heat then transfers through the tube wall to the material inside.

This design minimizes direct heat loss to the surrounding environment and ensures that energy is transferred efficiently to the target material. The constant mixing also enhances the rate of heat transfer, reducing the overall time and energy needed for a given process.

Unmatched Process Control and Versatility

Modern rotary furnaces are not just heaters; they are highly controllable processing environments. This allows for precise tailoring of the entire thermal cycle to meet specific material requirements.

Tailoring the Thermal Profile

Many rotary furnaces feature multiple, independently controlled heating zones along the length of the tube. This allows you to create a precise, custom temperature profile for the material as it travels.

Advanced digital controllers, some with up to 30 programmable segments, enable complex heating, dwelling, and cooling ramps. This level of control is critical for multi-stage processes like calcination or advanced material synthesis.

Adjusting Mechanical and Atmospheric Conditions

Beyond temperature, operators can control key mechanical and environmental variables. Adjusting the rotation speed changes the mixing dynamics, while modifying the tilt angle controls the residence time of the material in the tube.

Furthermore, these systems allow for tight atmosphere control. By introducing specific gases, you can run processes that require inert, oxidizing, or reducing environments, essential for applications like oxidation or specific chemical reactions.

Processing a Wide Range of Materials

This combination of control and dynamic heating makes rotary furnaces incredibly versatile. They are ideal for processing powders, granules, and other free-flowing solids.

Common applications include sintering to increase density, calcination to induce thermal decomposition, preparing specialty coatings, and running a wide array of high-temperature chemical reactions.

Understanding the Trade-offs

While powerful, rotary furnaces are not the universal solution for every thermal application. Acknowledging their specific limitations is key to making an informed decision.

Mechanical Complexity and Maintenance

The primary advantage—rotation—is also a source of mechanical complexity. The rotating seals, drive motor, and support bearings are moving parts that require regular inspection and maintenance compared to a simpler static furnace.

Material Suitability

The tumbling action is not suitable for all materials. Highly abrasive materials can cause premature wear on the inside of the tube, while very fragile or sticky materials may not flow or mix properly, leading to agglomeration or damage.

System Cost and Footprint

Generally, the initial capital cost of a rotary furnace can be higher than that of a static box furnace of similar capacity due to its mechanical components. Industrial-scale continuous systems also require a significant physical footprint.

Making the Right Choice for Your Process

Selecting the correct furnace depends entirely on your end goal. The rotary furnace excels where uniformity, control, and throughput are the dominant requirements.

- If your primary focus is product consistency: The unmatched temperature uniformity from rotation makes it the superior choice for producing homogenous powders and materials.

- If your primary focus is high throughput: The ability to operate continuously makes it ideal for industrial production where large volumes of material must be processed efficiently.

- If your primary focus is process development: The precise control over temperature profiles, residence time, and atmosphere provides an ideal platform for research and optimization.

Ultimately, the rotary furnace transforms static heating into a dynamic, precisely controlled process to achieve superior and repeatable material outcomes.

Summary Table:

| Advantage | Description |

|---|---|

| Uniform Heating | Constant rotation eliminates hot/cold spots for homogenous temperature distribution. |

| High Energy Efficiency | Indirect heating and mixing reduce heat loss and enhance transfer rates. |

| Precise Process Control | Multiple heating zones and programmable segments for tailored thermal profiles. |

| Versatility | Handles powders, granules, and various materials in oxidizing or inert atmospheres. |

| Continuous Workflow | Ideal for high-throughput applications like sintering and calcination. |

Ready to enhance your thermal processing with a custom rotary furnace solution?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization capabilities to precisely meet your unique experimental and production requirements.

Contact us today to discuss how our expertise can optimize your material outcomes and boost efficiency!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- What are the benefits of continuous sample movement in rotary tube furnaces? Boost Uniformity and Efficiency

- What are the common applications of a rotary tube furnace? Achieve Uniform Heating for Powders and Granules

- Why is efficient heat transfer important in rotary tube furnaces? Boost Uniformity and Throughput

- What are the key features of rotary tube furnaces regarding heat treatment? Achieve Uniform Heating and High Throughput