In high-performance manufacturing, hot pressing stands out for its unique ability to simultaneously apply intense heat and mechanical pressure. This combination allows for the creation of components with near-perfect density, superior mechanical strength, and exceptional uniformity by forcing material consolidation and eliminating internal voids in a highly controlled environment.

Hot pressing is more than a simple bonding method; it is a transformative process. By using controlled heat and pressure to fundamentally re-engineer a material's internal structure, it solves the core problem of defects like porosity, enabling the production of materials that approach their theoretical maximum performance.

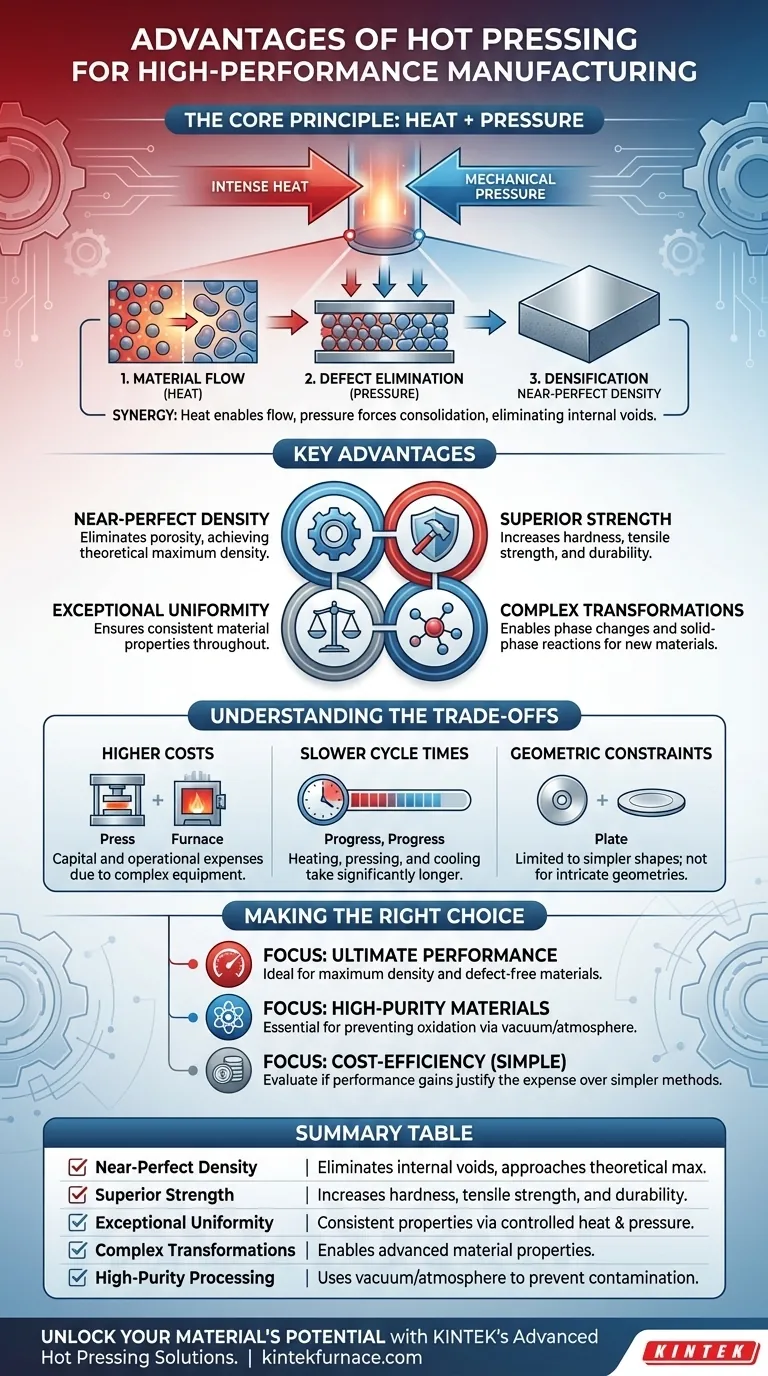

The Fundamental Principle: Combining Heat and Pressure

Hot pressing leverages the synergy between thermal energy and mechanical force to achieve results that neither could accomplish alone. This principle is the foundation of all its advantages.

How Heat Enables Material Flow

Applying heat to a material increases its atomic energy, making it softer and more plastic. This heightened malleability is crucial, as it allows the material's particles to deform and move.

Without sufficient heat, pressure alone would likely fracture the material's particles rather than fuse them together.

How Pressure Eliminates Internal Defects

While the material is in its heated, plastic state, mechanical pressure is applied. This force physically compacts the particles, squeezing out the empty spaces (porosity) between them.

The pressure ensures intimate contact between all particle surfaces, which is a prerequisite for strong, uniform bonding to occur throughout the material.

The Synergistic Effect on Densification

The combination of heat and pressure accelerates the process of densification, which is the elimination of porosity. The heat allows the material to yield, and the pressure provides the driving force for consolidation.

This results in a final product with a density that is exceptionally close to the theoretical maximum for that material, a feat difficult to achieve with other methods.

Achieving Near-Theoretical Material Properties

The goal of hot pressing is not just to form a shape, but to create a material with an optimized internal structure. This translates directly into superior real-world performance.

Maximizing Density and Reducing Porosity

Porosity is the primary enemy of material performance, acting as an internal weak point where fractures can initiate. Hot pressing directly attacks this problem.

By producing parts with minimal to no porosity, the process yields materials that are stronger, less permeable to fluids, and more reliable under stress.

Enhancing Mechanical Strength and Durability

A material's strength is directly linked to its density. By creating a dense, void-free structure, hot pressing significantly increases properties like hardness, tensile strength, and overall durability.

This is why the process is essential for producing high-wear components, armor, and cutting tools.

Enabling Complex Material Transformations

Hot pressing provides the precise, high-energy environment needed to drive phase transformations and solid-phase reactions.

This allows engineers to create entirely new material structures or alloys that would not form under normal conditions, unlocking advanced properties for specific applications.

Understanding the Trade-offs

While powerful, hot pressing is a specialized technique. Its advantages come with practical limitations that are critical to understand.

Higher Equipment and Operational Costs

The machinery required for hot pressing—combining a high-force press, a high-temperature furnace, and a vacuum or controlled atmosphere system—is complex and expensive.

This higher capital investment and operational cost means the process is typically reserved for applications where maximum performance justifies the expense.

Slower Cycle Times

Compared to simpler methods like cold pressing and sintering, hot pressing is a slower process. Heating, pressing, and cooling a component in a controlled manner takes significantly more time.

This makes it less suitable for high-volume, low-cost manufacturing where speed is a primary driver.

Constraints on Geometric Complexity

The need to apply uniform pressure generally limits hot pressing to simpler geometries. While effective for billets, discs, and plates, it is not practical for producing highly complex or intricate shapes.

Making the Right Choice for Your Application

Selecting the right manufacturing process requires aligning its capabilities with your primary goal.

- If your primary focus is ultimate performance and density: Hot pressing is the ideal choice, as it is specifically designed to eliminate porosity and achieve properties near the material's theoretical limit.

- If your primary focus is high-purity or reactive materials: The ability to use a vacuum or inert gas atmosphere makes hot pressing essential for preventing oxidation and contamination during consolidation.

- If your primary focus is cost-efficiency for simple shapes: You should evaluate whether the performance gains from hot pressing are necessary, as simpler methods like die pressing may be more economical.

Understanding these core principles allows you to select hot pressing not just for what it does, but for the fundamental material problems it is engineered to solve.

Summary Table:

| Key Advantage | Description |

|---|---|

| Near-Perfect Density | Eliminates internal voids for materials approaching theoretical maximum density. |

| Superior Mechanical Strength | Increases hardness, tensile strength, and durability in high-wear applications. |

| Exceptional Uniformity | Ensures consistent material properties through controlled heat and pressure. |

| Complex Transformations | Enables phase changes and solid-phase reactions for advanced material properties. |

| High-Purity Processing | Uses vacuum or controlled atmospheres to prevent oxidation and contamination. |

Unlock the Full Potential of Your Materials with KINTEK's Advanced Hot Pressing Solutions

Are you striving for maximum density, superior strength, and defect-free components in your high-performance manufacturing? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements.

Let us help you achieve near-theoretical material properties and solve core problems like porosity. Contact us today to discuss how our tailored hot pressing systems can enhance your research and production outcomes!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- What considerations guide the selection of heating elements and pressurization methods for a vacuum hot press furnace?

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?

- What role does a high-performance laboratory hot press machine play in curing? Unlock Superior Composite Strength

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%