For engineers and designers, the primary advantage of furnace brazing is its ability to produce exceptionally clean, strong, and dimensionally stable joints in a controlled atmosphere. By heating an entire assembly to a precise temperature, it melts a filler metal that flows into the joints via capillary action, creating a metallurgical bond that is often as strong as the parent materials themselves, all without the contamination or thermal stress common in other joining methods.

While many joining methods force a trade-off between strength, cleanliness, and material integrity, furnace brazing offers a unique solution. It leverages a controlled thermal environment to create superior, stress-free metallurgical bonds, making it the definitive choice for high-performance applications.

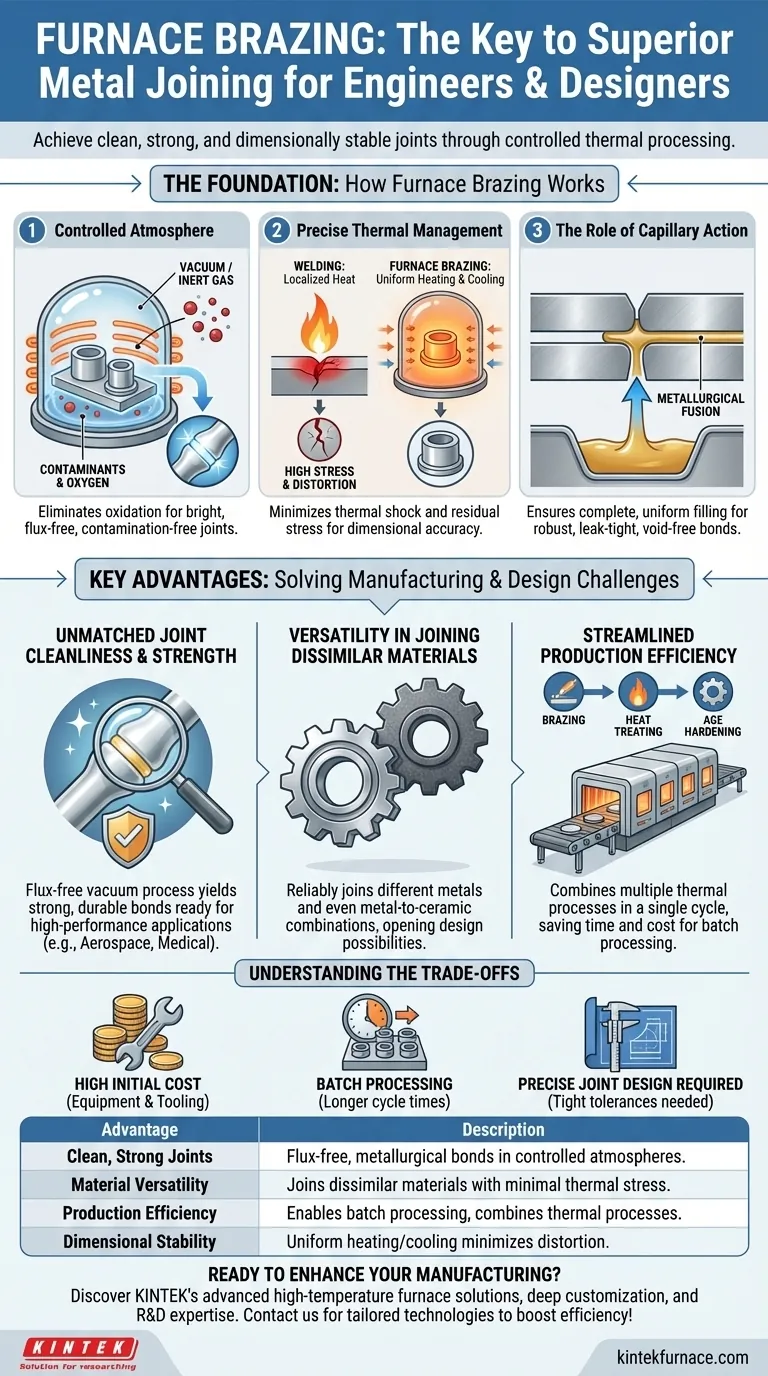

The Foundation: How Furnace Brazing Achieves Superior Joints

To understand the advantages of furnace brazing, it is essential to understand the core principles that set it apart. The process is not merely about melting metal; it's about controlling the entire environment to achieve a perfect metallurgical outcome.

A Controlled Atmospheric Environment

The defining feature of this process is the furnace's atmosphere, which is typically a vacuum or filled with an inert gas.

This controlled environment is critical because it eliminates oxygen and other contaminants. The result is a bright, clean joint that requires no post-process cleaning and is free from the oxides that can compromise strength and create failure points.

Precise Thermal Management

Unlike welding, which applies intense, localized heat, furnace brazing heats the entire assembly uniformly. This is followed by a controlled cooling cycle.

This method of uniform heating and cooling is crucial for minimizing thermal shock and residual stress. It ensures that components, especially those with complex geometries or thin walls, maintain their dimensional accuracy and structural integrity without distortion.

The Role of Capillary Action

Furnace brazing relies on capillary action to draw the molten filler metal into the tight-fitting gap between the base materials.

This natural phenomenon ensures the joint is completely and uniformly filled, creating a robust, leak-tight, and void-free connection across the entire interface. The resulting bond is a true metallurgical fusion, not just a surface connection.

Key Advantages for Manufacturing and Design

The principles of the process translate directly into tangible benefits that solve common manufacturing and design challenges, from material compatibility to production efficiency.

Unmatched Joint Cleanliness and Strength

Because the process often occurs in a vacuum, there is no need for flux, which is a common source of corrosion and contamination in other brazing methods.

This flux-free process yields exceptionally clean joints that are immediately ready for use. The metallurgical bond is incredibly strong and durable, making it ideal for applications in aerospace, medical devices, and high-performance tooling.

Versatility in Joining Dissimilar Materials

The lower temperatures and uniform heating of furnace brazing make it one of the few methods capable of reliably joining dissimilar materials.

This includes joining different metals (like copper to steel) or even metals to non-metals like ceramics. This capability opens up design possibilities that are impossible with fusion welding processes.

Streamlined Production Efficiency

Modern vacuum furnaces allow for multiple processes to be completed in a single cycle. It's possible to combine brazing, heat treating, and age hardening into one continuous operation.

This consolidation saves significant time, energy, and handling costs, making furnace brazing highly efficient for both small-batch and high-volume production runs. Furthermore, multiple assemblies can often be processed in a single furnace load.

Understanding the Trade-offs

No process is without its limitations. Objectivity requires acknowledging the areas where furnace brazing presents challenges.

Initial Equipment and Tooling Costs

Vacuum furnaces and the associated tooling represent a significant capital investment. This can make the initial barrier to entry higher compared to manual brazing or welding setups.

Batch Processing and Cycle Times

Furnace brazing is a batch process. The heating, soaking, and cooling cycles can take several hours, which may not be suitable for applications requiring immediate, continuous part flow.

Requirement for Precise Joint Design

The process relies entirely on capillary action, which demands very precise and consistent gaps between the parts being joined. Poor joint design or inconsistent part tolerances will result in a failed bond.

Making the Right Choice for Your Application

Choosing furnace brazing depends entirely on your project's specific requirements for performance, materials, and production scale.

- If your primary focus is mission-critical joint integrity: Furnace brazing is the superior choice for creating leak-tight, strong, and contaminant-free joints for aerospace, medical, or high-vacuum applications.

- If your primary focus is joining complex or dissimilar materials: This is one of the most reliable methods for bonding metals to ceramics or different alloys without compromising material properties.

- If your primary focus is manufacturing efficiency at scale: Leverage furnace brazing's ability to process many parts at once and combine thermal processes to reduce overall production time and cost.

By understanding its principles and trade-offs, you can leverage furnace brazing to solve your most demanding joining challenges.

Summary Table:

| Advantage | Description |

|---|---|

| Clean, Strong Joints | Produces flux-free, metallurgical bonds in controlled atmospheres, ideal for high-integrity applications. |

| Material Versatility | Joins dissimilar materials like metals and ceramics with minimal thermal stress. |

| Production Efficiency | Enables batch processing and combines multiple thermal processes in one cycle for cost savings. |

| Dimensional Stability | Uniform heating and cooling minimize distortion and residual stress for precise components. |

Ready to enhance your manufacturing with superior furnace brazing solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today via our contact form to discuss how our tailored furnace technologies can deliver clean, strong joints and boost your production efficiency!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- How do atmosphere furnaces contribute to ceramic manufacturing? Enhance Purity and Performance

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing