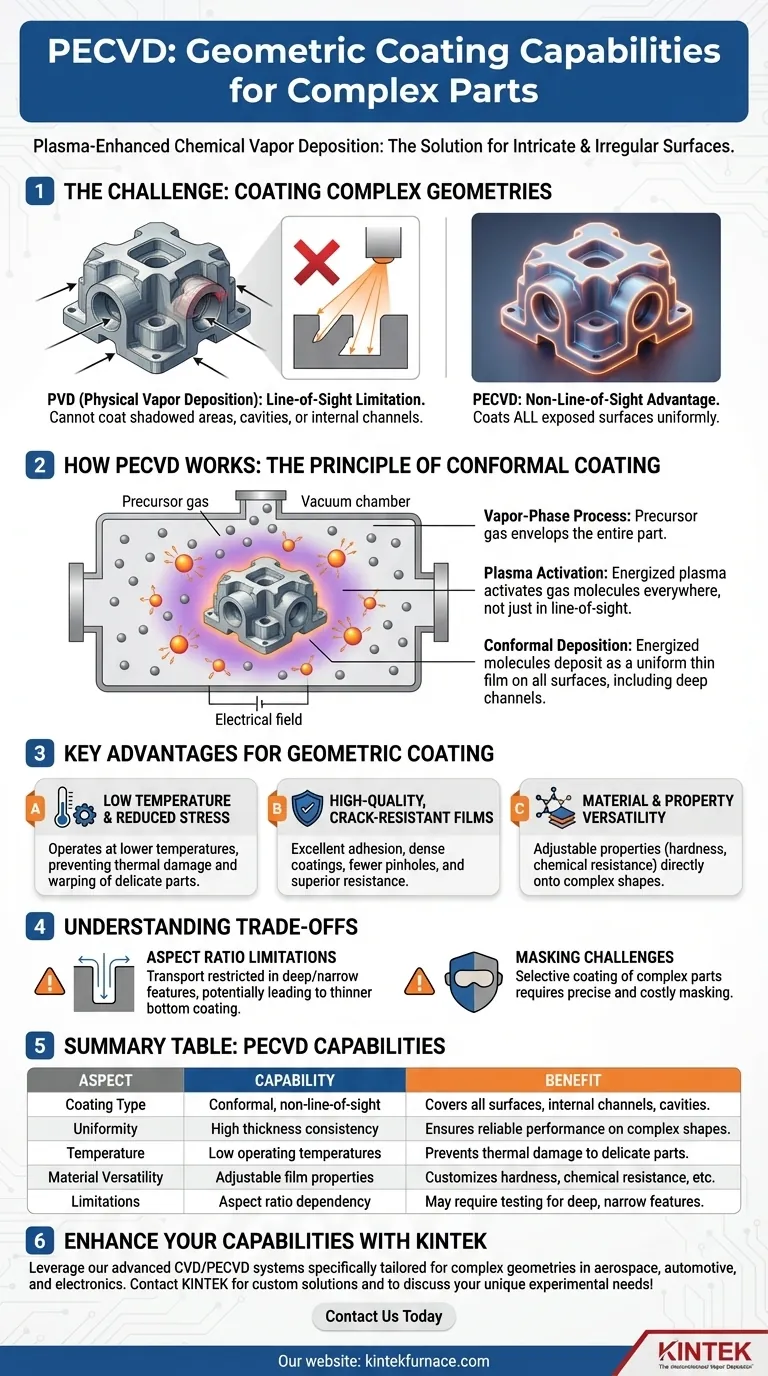

In short, Plasma-Enhanced Chemical Vapor Deposition (PECVD) is exceptionally well-suited for applying uniform, high-quality coatings to parts with complex geometries and irregular surfaces. Its fundamental process is not limited by line-of-sight, allowing it to coat intricate features that are inaccessible to many other deposition techniques. This capability makes it invaluable for advanced components in the aerospace, automotive, and electronics industries.

The true strength of PECVD lies in its process chemistry. By using an energized plasma to activate a precursor gas, the process enables deposition to occur conformally on all exposed surfaces, rather than just those in a direct line from a source.

The Principle of Conformal Coating in PECVD

The ability of PECVD to coat complex shapes stems directly from its non-directional nature. Unlike physical deposition methods, it relies on a gas that fills the entire processing chamber.

Non-Line-of-Sight Deposition

At its core, PECVD is a vapor-phase process. This means the material to be deposited is introduced as a gas (a "precursor") that envelops the component completely.

This is a fundamental distinction from Physical Vapor Deposition (PVD), which operates on a line-of-sight principle, essentially spraying material from a source onto a target. Any surface not in this direct line will not be coated.

How Plasma Enables Uniformity

The "plasma-enhanced" aspect is what drives the reaction. An electrical field energizes the precursor gas, creating a plasma within the chamber.

This plasma activates the gas molecules everywhere around the part. These energized molecules can then react and deposit as a solid thin film on all surfaces they touch, including internal channels, cavities, and the backside of the component.

Resulting Film Quality on Complex Parts

This process results in a conformal coating that mimics the topography of the substrate. The films are highly uniform in thickness, even over sharp edges and curved surfaces.

This uniformity ensures consistent performance across the entire part, which is critical for components with complex, functional surfaces.

Key Process Advantages for Geometric Coating

Several inherent benefits of the PECVD process make it ideal for preserving the integrity of geometrically complex and often delicate components.

Low Temperature and Reduced Stress

PECVD operates at significantly lower temperatures than traditional Chemical Vapor Deposition (CVD). This minimizes the risk of thermal stress, warping, or damage to the substrate material.

This is critical when coating precisely engineered parts or temperature-sensitive materials, ensuring the component's geometric accuracy is maintained.

High-Quality, Crack-Resistant Films

The resulting films exhibit excellent adhesion and are less prone to cracking. The uniform, low-stress deposition ensures the coating remains intact, even on parts with sharp corners or those subjected to mechanical stress.

The coatings are also dense and have fewer pinholes, providing superior corrosion and chemical resistance across the entire complex surface.

Material and Property Versatility

By adjusting the gas composition and plasma parameters, PECVD can create films with a wide range of properties. This allows for the engineering of specific characteristics, such as hardness, chemical resistance, or polymer-like qualities, directly onto a complex shape.

Understanding the Trade-offs

While powerful, PECVD is not without limitations. Acknowledging its trade-offs is key to making an informed decision.

Aspect Ratio Limitations

For extremely deep and narrow features, such as deep trenches or very small-diameter holes, the transport of precursor gas can become restricted.

This can lead to a thinner coating at the bottom of the feature than at the top. This is known as an aspect ratio dependency, and its effect must be evaluated for your specific geometry.

Masking and Selective Deposition

Because PECVD coats everything, selectively coating only a specific area of a complex part requires masking.

Creating a precise mask for an intricate 3D object can be complex and costly, sometimes adding significant overhead to the process.

Making the Right Choice for Your Goal

To determine if PECVD is the correct approach, consider the primary geometric challenge you are trying to solve.

- If your primary focus is coating parts with intricate designs, irregular surfaces, or internal channels: PECVD is a superior choice due to its non-line-of-sight, conformal coating capability.

- If your primary focus is coating simple, flat substrates where line-of-sight is not a concern: Other methods like PVD might be a more straightforward or cost-effective solution.

- If your primary focus is coating features with a very high aspect ratio (deep and narrow): You must conduct tests to validate that PECVD can provide the required coating uniformity at the bottom of the feature.

Ultimately, PECVD empowers you to apply advanced surface properties to components whose geometry makes them impossible to coat with conventional methods.

Summary Table:

| Aspect | Capability | Benefit |

|---|---|---|

| Coating Type | Conformal, non-line-of-sight | Covers all surfaces, including internal channels and cavities |

| Uniformity | High thickness consistency | Ensures reliable performance on complex shapes |

| Temperature | Low operating temperatures | Prevents thermal damage to delicate parts |

| Material Versatility | Adjustable film properties | Customizes hardness, chemical resistance, and more |

| Limitations | Aspect ratio dependency | May require testing for deep, narrow features |

Enhance your lab's capabilities with KINTEK's advanced PECVD solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces and CVD/PECVD systems tailored for complex geometries. Our deep customization ensures precise performance for aerospace, automotive, and electronics applications. Contact us today to discuss how we can meet your unique experimental needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings

- How is silicon dioxide (SiO2) used in PECVD applications? Key Roles in Microfabrication