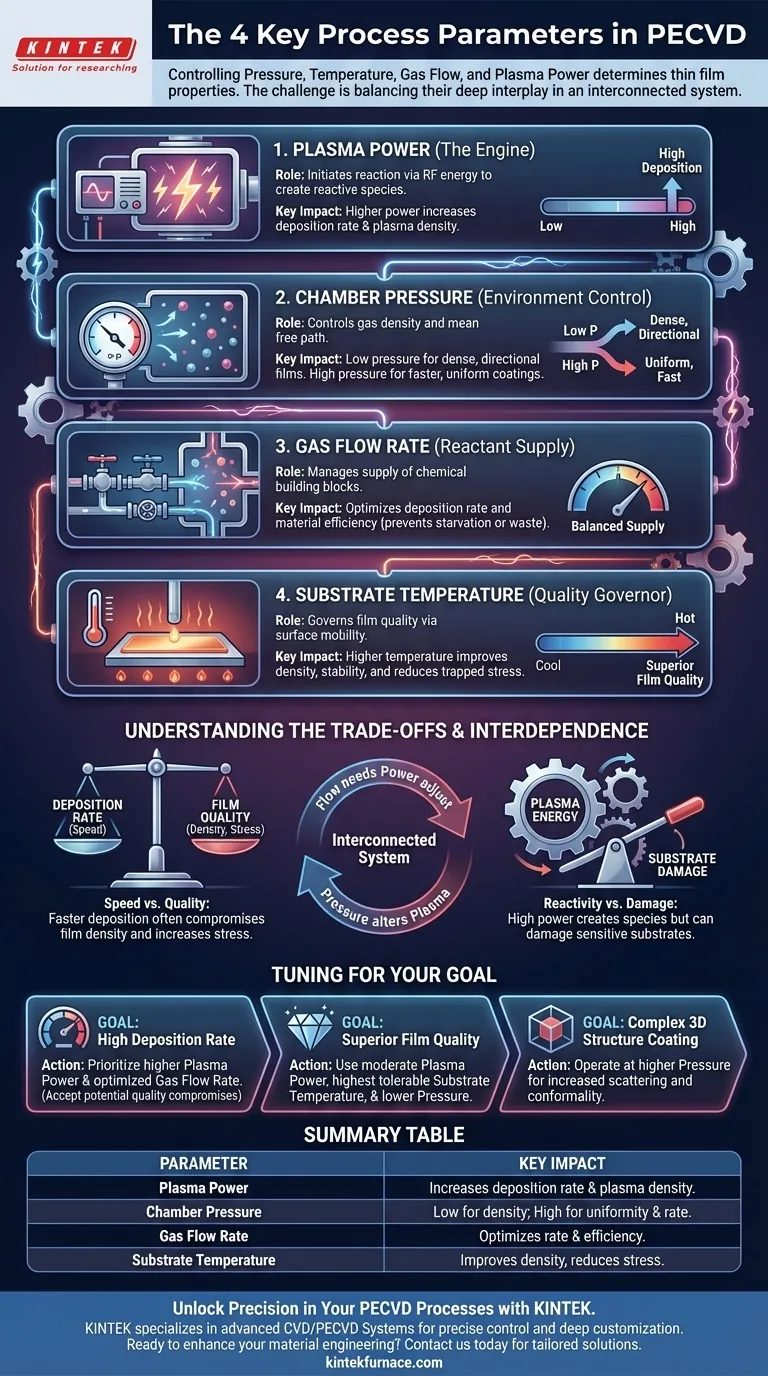

In Plasma-Enhanced Chemical Vapor Deposition (PECVD), the four key process parameters you must control are Pressure, Temperature, Gas Flow Rate, and Plasma Power. These variables are the fundamental levers that determine the chemical reactions in the chamber and, consequently, the final properties of the deposited thin film.

The core challenge of PECVD is not simply knowing these four parameters, but understanding their deep interplay. They are not independent knobs to turn; they form an interconnected system where adjusting one directly impacts the effects of the others, requiring a balanced approach to achieve the desired film characteristics.

Deconstructing the Core PECVD Parameters

To truly master the PECVD process, you must understand the specific role each parameter plays. Think of it as a tightly controlled chemical assembly line where each parameter governs a critical stage of production.

H3: Plasma Power: The Engine of the Reaction

Plasma power, typically delivered via a radio frequency (RF) generator, is what initiates the entire process. It provides the energy to dissociate stable precursor gases into highly reactive radicals and ions.

Increasing plasma power generally creates a denser plasma with more reactive species. This directly leads to a higher deposition rate.

H3: Chamber Pressure: Controlling the Plasma Environment

Pressure governs the density of gas molecules in the chamber and, critically, the mean free path—the average distance a particle travels before colliding with another.

At low pressure, particles travel further, leading to more energetic and directional bombardment of the substrate surface. This can be beneficial for creating dense films but may also cause damage.

At high pressure, frequent collisions occur in the gas phase. This can increase the deposition rate and improve the uniformity of the film over complex topographies but may result in less dense or even powdery films.

H3: Gas Flow Rate: Managing the Reactant Supply

Gas flow rate determines how quickly reactant gases are introduced into and removed from the chamber. It essentially controls the concentration of available chemical building blocks for the film.

If the flow rate is too low, the process becomes "reactant-starved," limiting the deposition rate. If it's too high, precursor gases may not have enough residence time in the plasma to react efficiently, wasting material.

H3: Substrate Temperature: Governing Film Quality

While PECVD is prized for its low-temperature operation compared to conventional CVD, substrate temperature remains a crucial lever for controlling film quality.

Higher temperatures provide more thermal energy to the atoms and molecules that have landed on the substrate. This increased surface mobility allows them to move around, find more stable positions in the film's structure, and release trapped stress. This results in denser, more stable, and often less stressed films.

Understanding the Trade-offs

Optimizing a PECVD process is always a balancing act. Pushing one parameter to its extreme to maximize a single property, like deposition rate, will almost certainly compromise another, like film quality.

H3: Deposition Rate vs. Film Quality

There is a classic trade-off between speed and quality. Increasing plasma power and gas flow will accelerate deposition, but this rapid growth can lead to defects, higher internal stress, and poor structural density in the film. A slower, more controlled deposition at moderate power and higher temperature often yields a superior film.

H3: Plasma Energy vs. Substrate Damage

While high plasma power creates the reactive species needed for deposition, it also increases the energy of ion bombardment on the substrate. For sensitive substrates or devices, this bombardment can cause significant damage, degrading the material's electrical or optical performance.

H3: The Interdependence of Parameters

No parameter exists in a vacuum. For example, increasing the gas flow rate might require a corresponding increase in plasma power to ensure the additional gas is effectively dissociated. Similarly, changing the pressure will alter the nature of the plasma, potentially requiring adjustments to power and gas chemistry to maintain stability.

How to Tune Parameters for Your Goal

Your specific process "recipe" will depend entirely on the desired outcome for your thin film. Use these principles as your starting point for process development.

- If your primary focus is high deposition rate: Prioritize higher plasma power and an optimized gas flow rate, but be prepared to accept potential compromises in film stress and density.

- If your primary focus is superior film quality (low stress, high density): Use a moderate plasma power, the highest substrate temperature your material can tolerate, and a lower pressure to promote a well-structured film.

- If your primary focus is coating a complex 3D structure: Consider operating at a higher pressure to increase gas-phase scattering, which makes the deposition less directional and more conformal.

By understanding these fundamental relationships, you can move beyond simple recipes and begin to engineer materials with precision.

Summary Table:

| Parameter | Role in PECVD | Key Impact |

|---|---|---|

| Plasma Power | Initiates reactions via RF energy | Higher power increases deposition rate and plasma density |

| Chamber Pressure | Controls gas density and particle collisions | Low pressure for dense films, high pressure for uniformity |

| Gas Flow Rate | Manages reactant supply and removal | Optimizes deposition rate and material efficiency |

| Substrate Temperature | Governs film quality and structure | Higher temperature improves density and reduces stress |

Unlock Precision in Your PECVD Processes with KINTEK

Struggling to balance PECVD parameters for optimal thin film results? KINTEK specializes in advanced high-temperature furnace solutions, including our CVD/PECVD Systems, designed to deliver precise control over pressure, temperature, gas flow, and plasma power. Leveraging exceptional R&D and in-house manufacturing, we provide deep customization to meet your unique experimental needs—whether you're aiming for high deposition rates, superior film quality, or conformal coatings on complex structures. Our expertise ensures reliable performance for diverse laboratory applications.

Ready to enhance your material engineering? Contact us today to discuss how our tailored solutions can drive your success!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is PECVD specification? A Guide to Choosing the Right System for Your Lab

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods

- What are the classifications of CVD based on vapor characteristics? Optimize Your Thin Film Deposition Process