At its core, a hot press sintering furnace is a sophisticated system designed to simultaneously apply high temperature and immense pressure within a controlled atmosphere. Its primary features are not just individual components, but integrated systems working in concert: a hydraulic system for pressure, a heating and insulation system for temperature, a vacuum system for atmospheric control, and a robust cooling system to maintain structural integrity and precision.

A hot press furnace is best understood not as a simple oven, but as a precision instrument. Its defining features work together to force material densification, achieving properties that are impossible to obtain through heat alone.

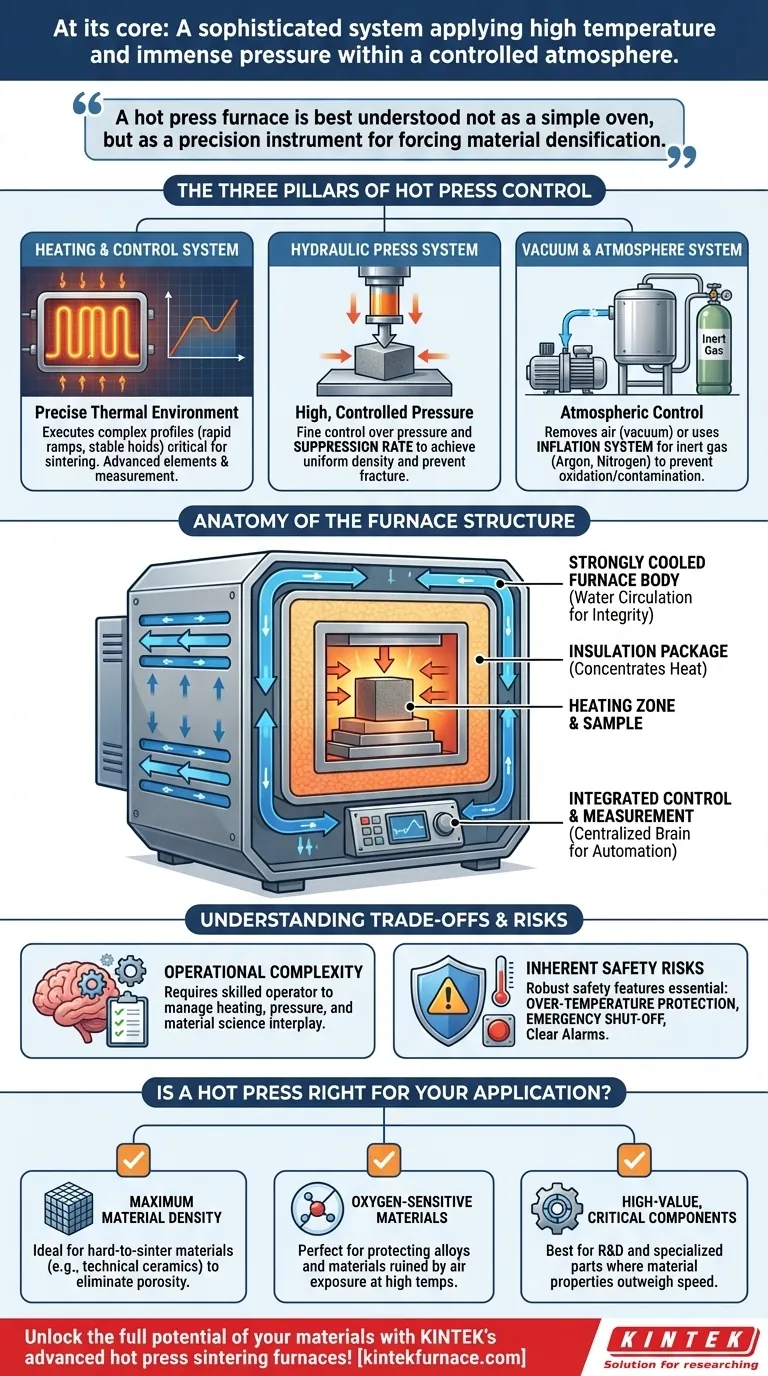

The Three Pillars of Hot Press Control

The power of a hot press furnace comes from its ability to precisely manage three critical variables: temperature, pressure, and atmosphere. Each is governed by a dedicated set of features.

The Heating and Control System

A hot press furnace provides exceptionally high-precision control over the thermal environment. This is achieved through a combination of advanced heating elements and a sophisticated temperature measuring system.

This allows the furnace to execute complex temperature profiles, including rapid ramps and extended periods of constant, stable temperature, which are critical for many sintering processes.

The Hydraulic Press System

The "press" in hot press comes from an integrated hydraulic system. This feature allows for the application of high, controlled pressure onto the material during the heating cycle.

Modern systems offer fine control over not just the final pressure but also the suppression rate—how quickly that pressure is applied. This precision is essential for preventing material fracture and achieving uniform density.

The Vacuum and Atmosphere System

To prevent oxidation and contamination at high temperatures, these furnaces incorporate a powerful vacuum system. Removing air from the chamber is a prerequisite for processing sensitive materials like advanced ceramics and certain metal alloys.

Additionally, an inflation system is often included. This allows for the backfilling of the chamber with a specific inert gas, such as argon or nitrogen, creating a tailored, non-reactive atmosphere for the sintering process.

Anatomy of the Furnace Structure

The physical design of the furnace is engineered to contain extreme forces and temperatures while ensuring operational safety and precision.

The Furnace Body and Insulation

The furnace body is the main structural vessel. Inside, a high-performance insulation package surrounds the heating zone, ensuring that heat is concentrated on the sample and not lost to the furnace body.

The Critical Role of Water Cooling

A defining feature is a strongly cooled furnace body. Channels within the furnace walls circulate water to actively remove heat from the structure.

This may seem counterintuitive, but it is essential. Cooling the body prevents thermal expansion and warping, maintains vacuum integrity, and protects sensitive components, ensuring the furnace can operate reliably and precisely for years.

Integrated Control and Measurement

A centralized control system acts as the brain of the furnace. It integrates and automates the function of all other systems—heating, pressure, vacuum, and cooling—allowing the user to program and monitor the entire sintering cycle from a single interface.

Understanding the Trade-offs and Risks

While powerful, a hot press furnace is a complex piece of equipment with inherent trade-offs and necessary safety considerations.

Operational Complexity

The high degree of control means the process is not "set it and forget it." It requires a skilled operator who understands the interplay between heating rates, pressure application, and material science to develop a successful process recipe.

Inherent Safety Risks

The combination of high temperature, high pressure, and high voltage requires robust safety features. These are not optional add-ons but core components of the design.

Essential safety mechanisms include over-temperature protection, which automatically cuts power if a set point is exceeded, and emergency shut-off buttons that can halt all operations instantly. Clear alarm systems are also critical to alert operators to any system malfunction.

Is a Hot Press Furnace Right for Your Application?

Choosing this technology depends entirely on your material and your final goal.

- If your primary focus is maximum material density: Hot pressing is an exceptional choice for eliminating porosity and achieving near-theoretical density in hard-to-sinter materials like technical ceramics.

- If your primary focus is processing oxygen-sensitive materials: The integrated vacuum and controlled atmosphere systems make this technology ideal for protecting materials that would be ruined by air exposure at high temperatures.

- If your primary focus is high-value, performance-critical components: Hot pressing is best suited for research, development, and the production of specialized parts where material properties are more important than production speed.

By understanding these integrated systems, you can leverage hot press sintering not just as a furnace, but as a precise tool for engineering materials from the inside out.

Summary Table:

| Feature Category | Key Components | Primary Function |

|---|---|---|

| Heating System | Advanced heating elements, temperature sensors | Provides precise thermal control and stable profiles |

| Hydraulic System | Hydraulic press, suppression rate control | Applies high pressure for uniform material densification |

| Vacuum/Atmosphere System | Vacuum pumps, inert gas inflation | Prevents oxidation and contamination in sensitive materials |

| Cooling System | Water-cooled furnace body | Maintains structural integrity and protects components |

| Control System | Centralized automation interface | Integrates and monitors all systems for precise operation |

Unlock the full potential of your materials with KINTEK's advanced hot press sintering furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental requirements are met precisely. Contact us today to discuss how our expertise can enhance your research and development outcomes!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a hot press machine work? Master Heat, Pressure, and Time for Perfect Results

- What is a hot press used for? Fabricate Dense, High-Performance Materials

- What is the mechanism of hot press? Achieve Full Densification for Advanced Materials

- What are the applications of hot pressing? Achieve Maximum Material Performance

- What is the process of vacuum hot pressing? Achieve Ultra-Dense, High-Purity Materials